Extrusion forming device for agricultural biomass fuel

A biomass fuel and extrusion molding technology, which is applied in the direction of material molding presses, presses, manufacturing tools, etc., can solve the problem of insufficient density of extruded products, insufficient force of extrusion screw, and incomplete specifications of molded products and other problems, to achieve the effect of simple structure, high compaction rate and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing:

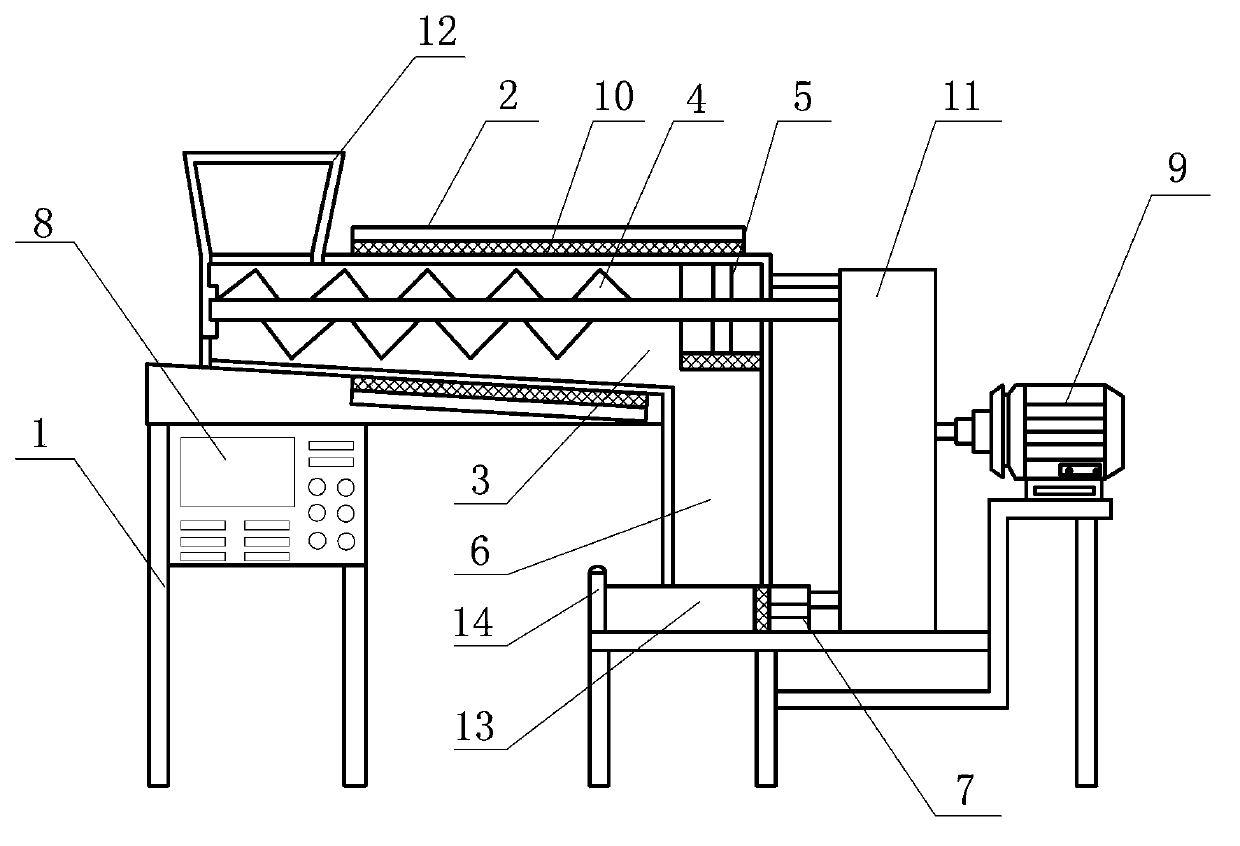

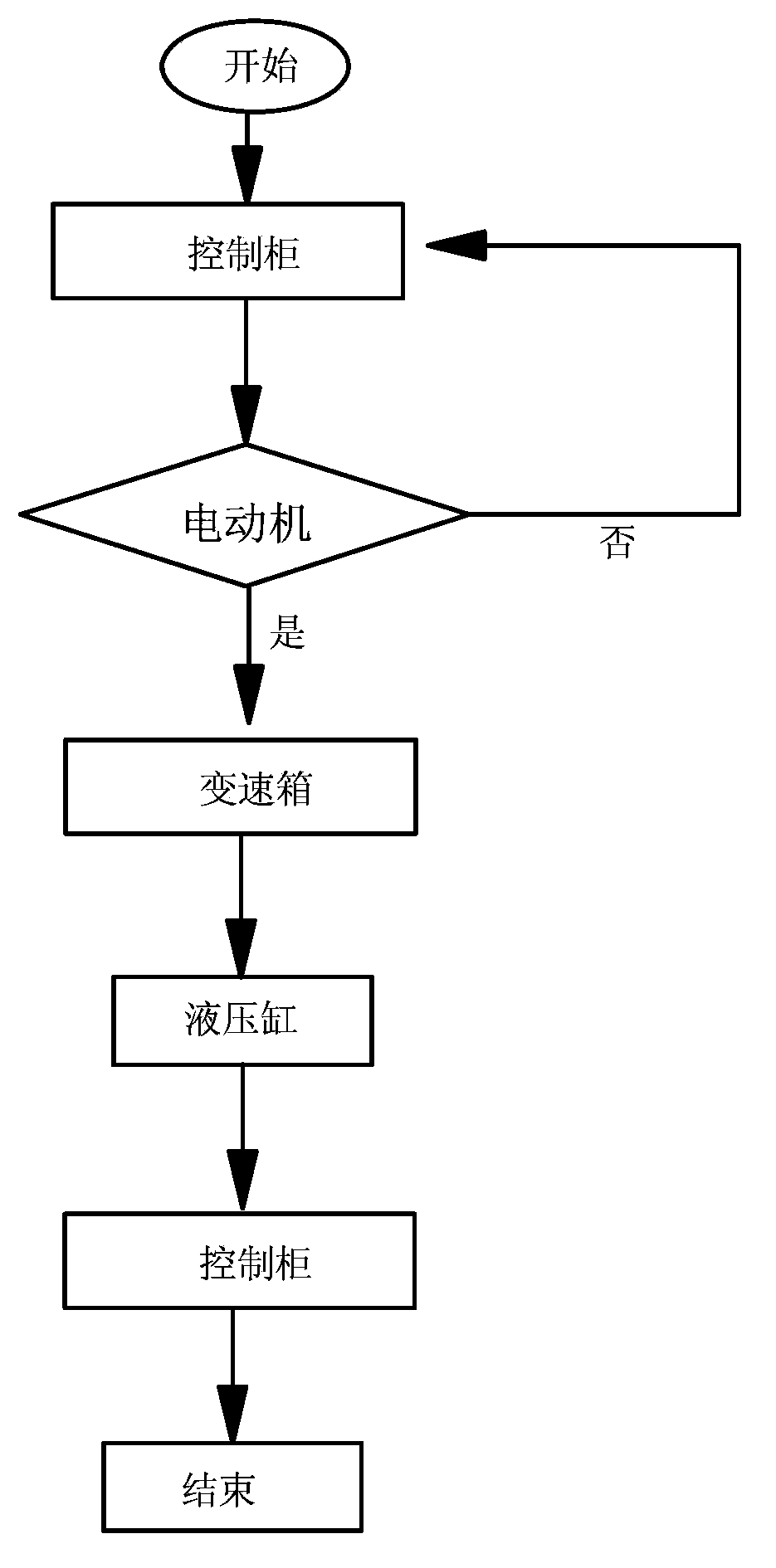

[0021] An agricultural biomass fuel extrusion molding device, including a frame 1, a shell 2, a channel 3, an auger feeding device 4, a compression hydraulic cylinder 5, a compression channel 6, an extrusion hydraulic cylinder 7, a control cabinet 8, and a motor 9 , Heating plate 10, gearbox 11, feed hopper 12, compression cavity 13, discharge port 14.

[0022] The frame 1 also has a housing 2, the housing 2 has an inclined channel 3, and an auger feeding device 4 and a compression hydraulic cylinder 5 are arranged in the channel 3, and a compression channel 6 is located below the compression hydraulic cylinder 5. A squeeze hydraulic cylinder 7 is arranged below the compression channel 6 ; a motor 9 is arranged on one side of the casing 2 , and a control cabinet 8 is also arranged on the frame 1 .

[0023] The motor 9 as the power plant of the present invention is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com