Aqueous cleaning agent

A water-based cleaning agent and amine salt technology, applied in the direction of non-surface active detergent composition, detergent composition, detergent compounding agent, etc., can solve the problems of chip residue, surface stickiness, etc., and achieve excellent rust resistance, Excellent hard water stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

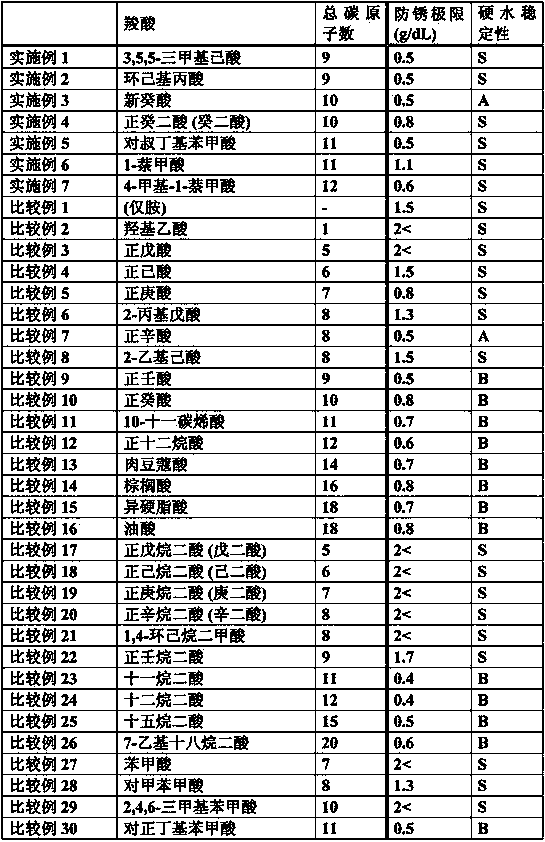

Embodiment 1~7、 comparative example 1~36

[0062] Various carboxylic acids shown in Table 1 were mixed with N-methyldiethanolamine and diluted with water to prepare aqueous amine salt solutions of carboxylic acids. This amine salt aqueous solution was used as a sample, and the rust prevention and hard water stability were evaluated. The evaluation results are also shown in Table 1. The evaluation method is as follows.

[0063] (Evaluation method of rust resistance)

[0064] 1) Measure 2.00g of N-methyldiethanolamine and carboxylic acid in a 100mL beaker such that "amine / acid equivalent ratio = 3".

[0065] 2) Add about 20 mL of ion-exchanged water, and dissolve it uniformly while heating and stirring.

[0066] 3) Quantitatively transfer the dissolved amine salt solution into a 100mL graduated cylinder with a stopper, dilute it with ion-exchanged water, and set the volume to 100mL to prepare an aqueous solution with a concentration of 2.0g / dL.

[0067] 4) Mix the ion-exchanged water and the above aqueous solution at...

Embodiment 8、9、10

[0083] Examples 8 and 9 in Table 2 show recipes (stock solutions) that are assumed to be cleaning agents for both iron and aluminum, and Example 10 shows recipes (stock solutions) that are supposed to be cleaning agents dedicated to aluminum. These stock solutions were diluted with water and evaluated. Specifically, in addition to the above-mentioned rust resistance and hard water stability, defoaming and the degree of discoloration of the aluminum flakes were evaluated by the methods shown below.

[0084] (defoaming)

[0085] Evaluation was performed by a cylinder method (Silinder method). Specifically, 98 mL of tap water was placed in a 100 mL graduated cylinder with a stopper, 2 mL of the stock solution was added, and lightly shaken to prepare a 2% by volume dilution. Vigorously shake the barrel up and down for 5 seconds, then let it stand. The time at which 50% of the liquid interface was observed was recorded as defoaming time (seconds).

[0086]

[0087] When the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com