Rare earth Sc micro-alloyed Al-Mg-Si-Cu alloy and preparation method thereof

A technology of al-mg-si-cu-sc and microalloying, applied in the field of rare earth Sc microalloyed Al-Mg-Si-Cu alloy and its preparation, to achieve simple preparation process and heat treatment method, and improve comprehensive performance , the effect of uniform grain size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] This embodiment prepares the rare earth Sc microalloyed Al-Mg-Si-Cu alloy according to the following steps:

[0042] Step 1: Preparation of Alloy Ingot

[0043] 1a, ingredients: according to the mass percentage of 97.45% Al, 0.9% Mg, 0.6% Si, 0.7% Cu, 0.2% Mn and 0.15% Sc, weigh 1065.7g metal Al (purity is 99.99%), 23.2gAl-50.38% Mg master alloy, 71.4gAl-10.92%Si master alloy, 25gAl-10.4%Mn master alloy, 18.2gAl-50.02%Cu master alloy and 96.5gAl-2.02%Sc master alloy are batched, and the total mass of the batch is 1300g;

[0044] 1b. Melting: First, add metal Al, Al-Mn master alloy, Al-Si master alloy and Al-Cu master alloy as raw material group A into a crucible preheated to 280°C, heat to 730°C, and keep the temperature until the raw material group When A softens and collapses, sprinkle a covering agent on the surface of the raw material group A (the quality of the covering agent is 6.5g); continue to keep constant temperature until the raw material group A is complet...

Embodiment 2

[0058] This example prepares the Al-Mg-Si-Cu-0.3Sc alloy material according to the same steps as Example 1, the difference is that in step 1a, 97.3% Al, 0.9% Mg, 0.6% Si, 0.7% Cu, 0.2% Mn And the mass percentage of 0.3% Sc, weigh 969.1g metal Al (purity is 99.99%), 23.2gAl-50.38%Mg master alloy, 71.4gAl-10.92%Si master alloy, 25gAl-10.4%Mn master alloy, 18.2gAl- 50.02% Cu master alloy and 193.1g Al-2.02% Sc master alloy are batched, and the total mass of the batch is 1300g;

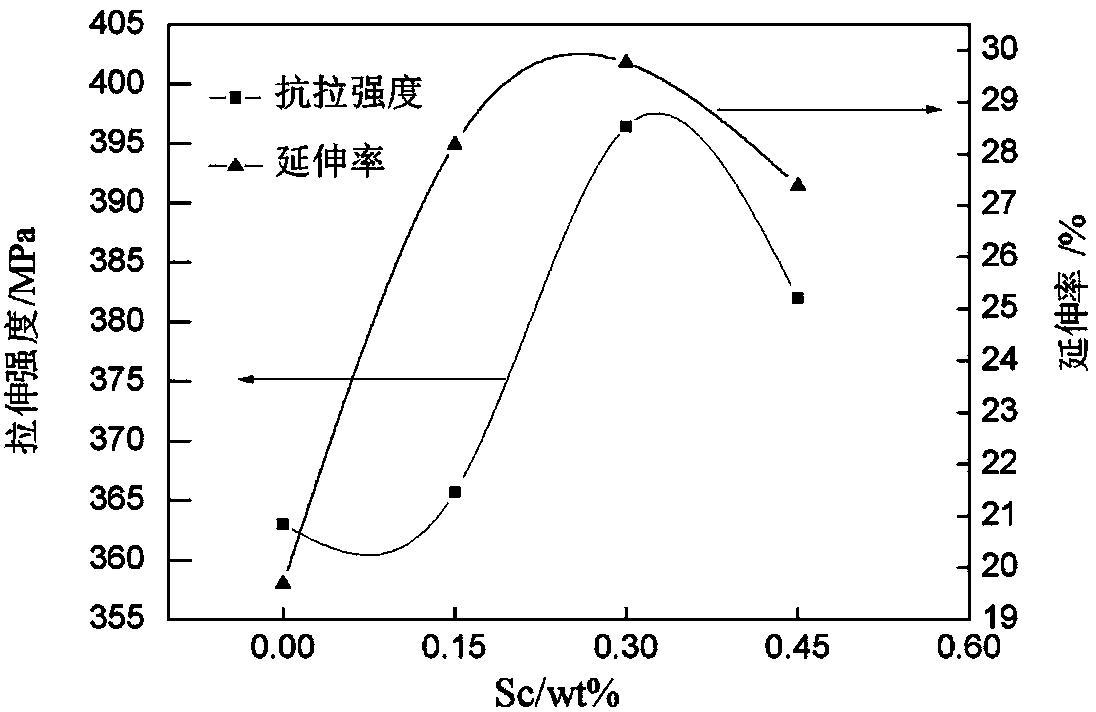

[0059] Carry out room temperature tensile test to Al-Mg-Si-Cu-Mn-0.3Sc alloy material by the same method of embodiment 1, the obtained mechanical performance index is: tensile strength is 396.4MPa, and yield strength is 377MPa, and elongation is 29.76 %, see Table 1 for specific data.

Embodiment 3

[0061] This example prepares the Al-Mg-Si-Cu-0.45Sc alloy material according to the same steps as Example 1, the difference is that in step 1a, 97.15% Al, 0.9% Mg, 0.6% Si, 0.7% Cu, 0.2% Mn And the mass percentage of 0.45% Sc, weigh 872.6g metal Al (purity is 99.99%), 23.2gAl-50.38%Mg master alloy, 71.4gAl-10.92%Si master alloy, 25gAl-10.4%Mn master alloy, 18.2gAl- 50.02% Cu master alloy and 289.6g Al-2.02% Sc master alloy are batched, and the total mass of the batch is 1300g;

[0062] Carry out the tensile test at room temperature to Al-Mg-Si-Cu-0.45Sc alloy material by the same method of embodiment 1, the obtained mechanical property index is: tensile strength is 382MPa, and yield strength is 371MPa, and elongation is 27.38%, specifically See Table 1 for the data.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com