Brushless direct-current motor high-performance speed measuring method

A brushed DC motor, high-performance technology, used in linear/angular velocity measurement, measurement device, velocity/acceleration/shock measurement, etc., and can solve problems such as limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Specific embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings, but it is not intended to limit the present invention. according to figure 1 The application process implementation:

[0017] (1) Obtain the correction coefficient of the displacement in each Hall state.

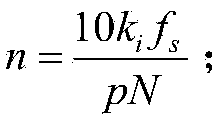

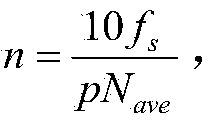

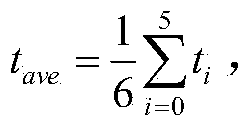

[0018] In the open-loop state, the motor runs at a constant speed and direction, and the installation error of the three-phase Hall sensor causes the electrical angle of the motor to be different in each Hall state, such as figure 2 shown. When the Hall signal does not change, count the high-frequency clock signal until the Hall signal changes, read and save the count value of the motor in the previous Hall state, and then obtain the running time of the motor in each Hall state . Among them, the corresponding relationship between each Hall state and the count value is: three-phase Hall signal h a 、h b 、h c is "101", the count v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com