A fault detection method for fused magnesia furnace operation based on common subspace separation

A technology of an electric fused magnesia furnace and a detection method, applied in the directions of electrical program control, comprehensive factory control, comprehensive factory control, etc., can solve the problems of difficulty in determining a new sampling operation mode, large operation volume, and ignoring the similarity of modes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

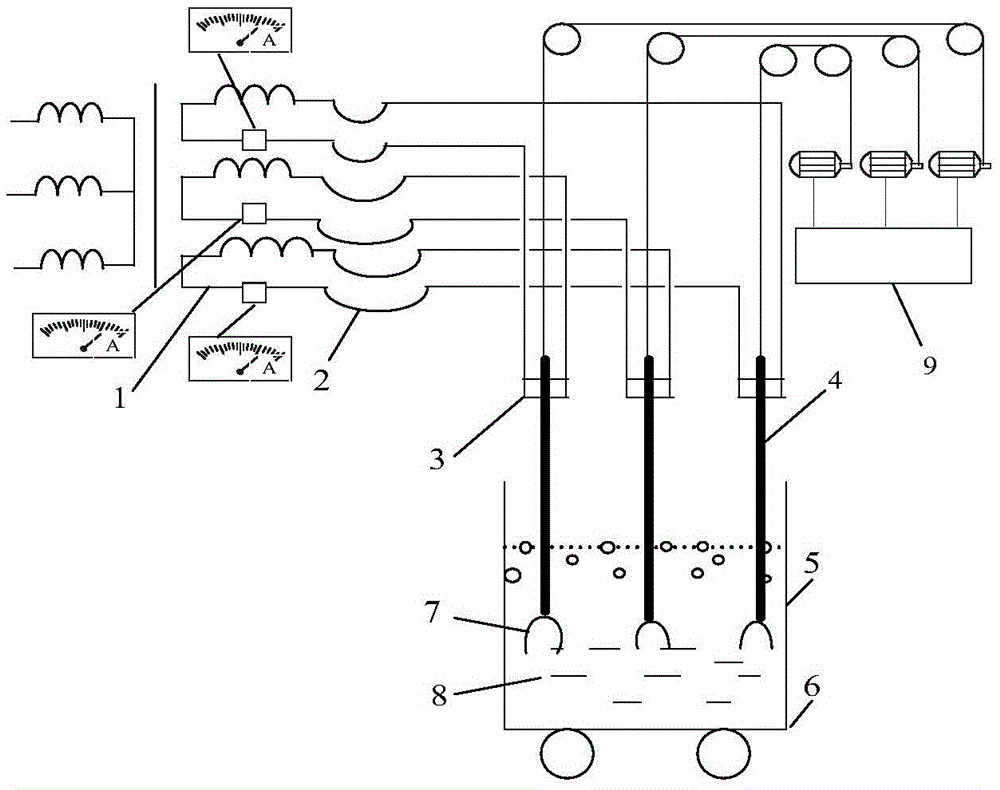

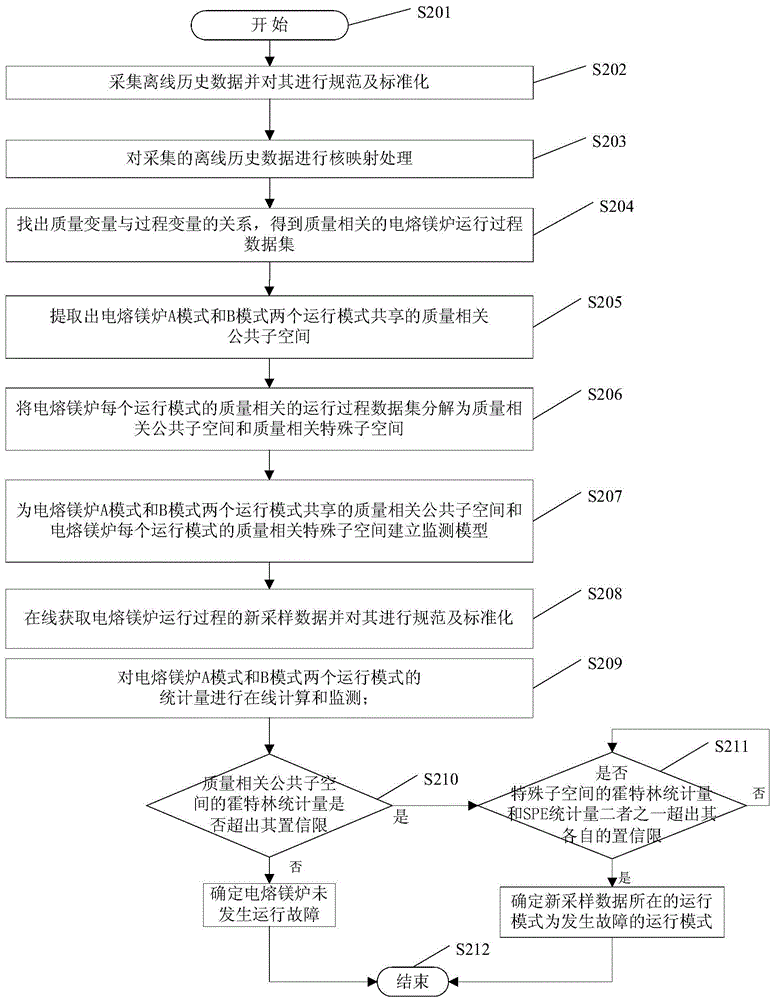

[0065] An embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0066] The invention divides the operation of the fused magnesia furnace into multi-modes according to the change of the feeding material of the fused magnesia furnace, that is, the difference of the operation modes is reflected in the production raw materials. Due to the needs of the production process, the production raw materials will be adjusted. Under different production materials, the normal production current, voltage and electrode position are also different, but they all operate in a stable state.

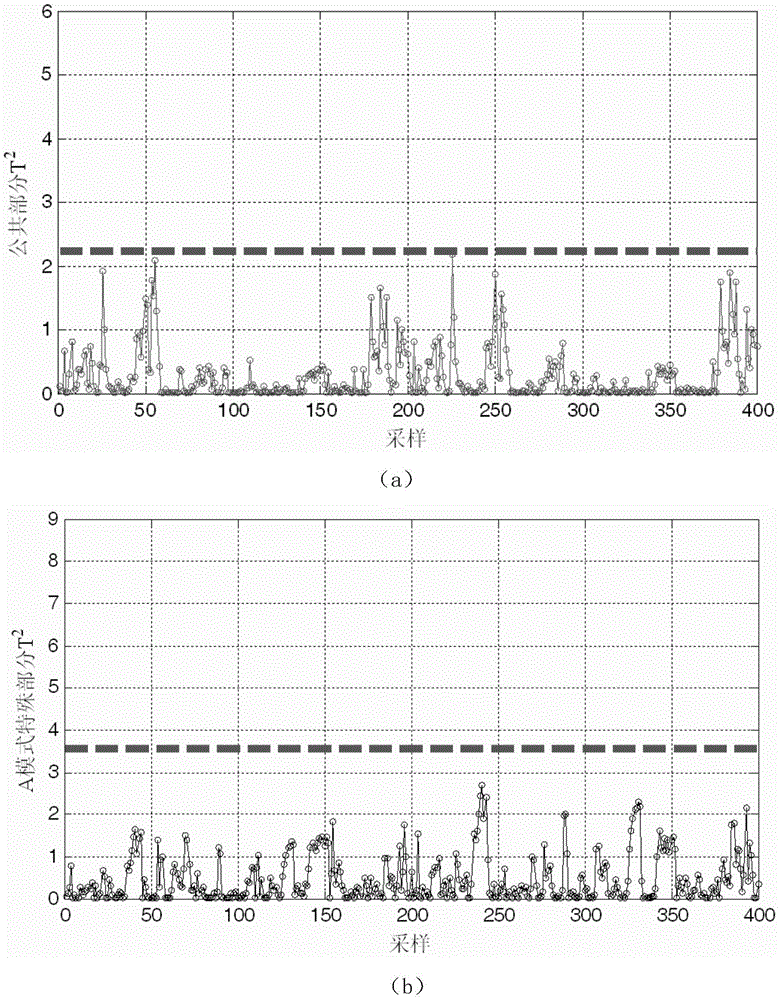

[0067] In the present embodiment, there are two kinds of operation modes in the operation process of the fused magnesia furnace, and the operation modes of the fused magnesia furnace when the production raw materials are magnesite block and magnesite powder are respectively represented below with mode A and mode B; The process data and quality ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com