Welding operation training simulation method and system based on augmented reality

A technology of augmented reality and simulation method, which is applied in the field of welding manufacturing, can solve the problems of inaccurate capture of the spatial motion trajectory of the simulated welding torch, unsatisfactory visual effect of the welding process, and unrealistic dynamic simulation effect, so as to avoid the complexity of the global calibration process, The dynamic simulation effect is real and the effect of immersion is strong

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

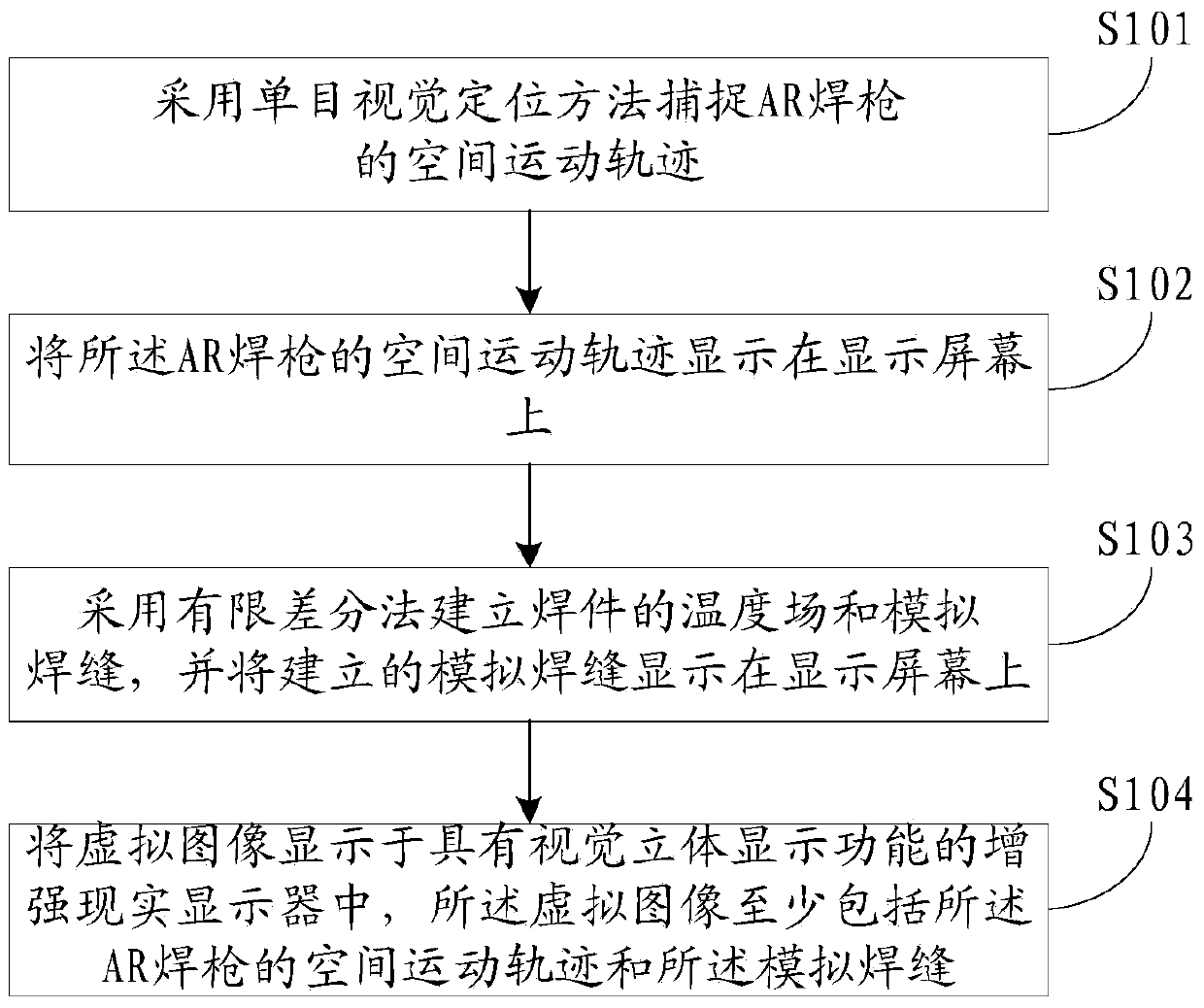

[0029] Embodiment 1. An augmented reality-based welding operation training simulation method. Combine below Figure 1-Figure 7 The method provided by the present invention is described in detail.

[0030] figure 1 Among them, S101, using a monocular vision positioning method to capture the spatial movement trajectory of the AR welding torch.

[0031] Specifically, in a real environment, the welding operator holds the AR welding torch and performs welding operations on the simulated weldment. At this time, the AR welding torch can be spatially positioned so as to capture the spatial movement trajectory of the AR welding torch.

[0032] The spatial positioning system used in this embodiment is an active monocular vision positioning system, which consists of a luminescent ball placed on the surface of the AR welding torch, a camera mounted on a fixed bracket, an accelerometer, a gyroscope and a computer.

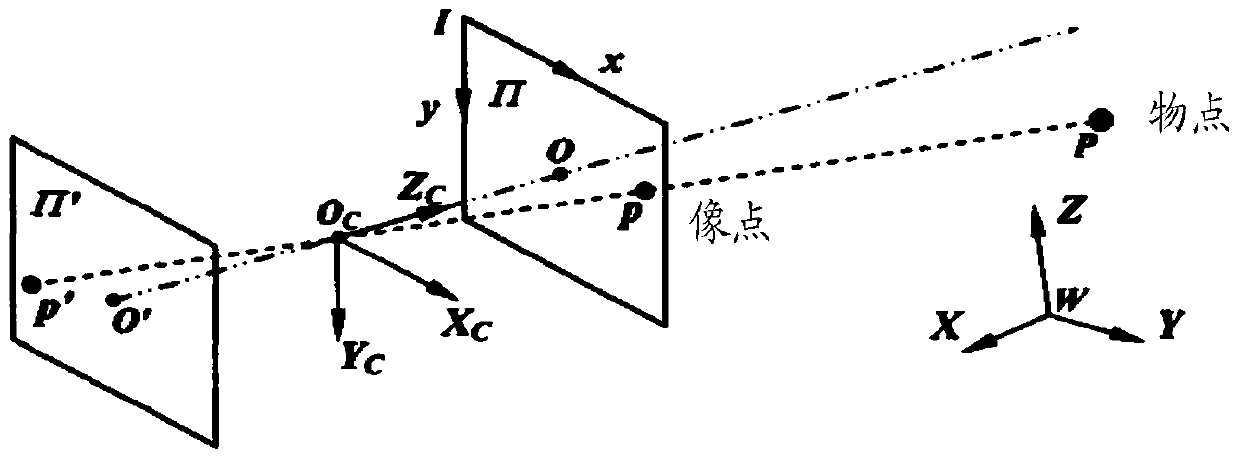

[0033] Computer vision simulates the principle of biological vision. Im...

Embodiment 2

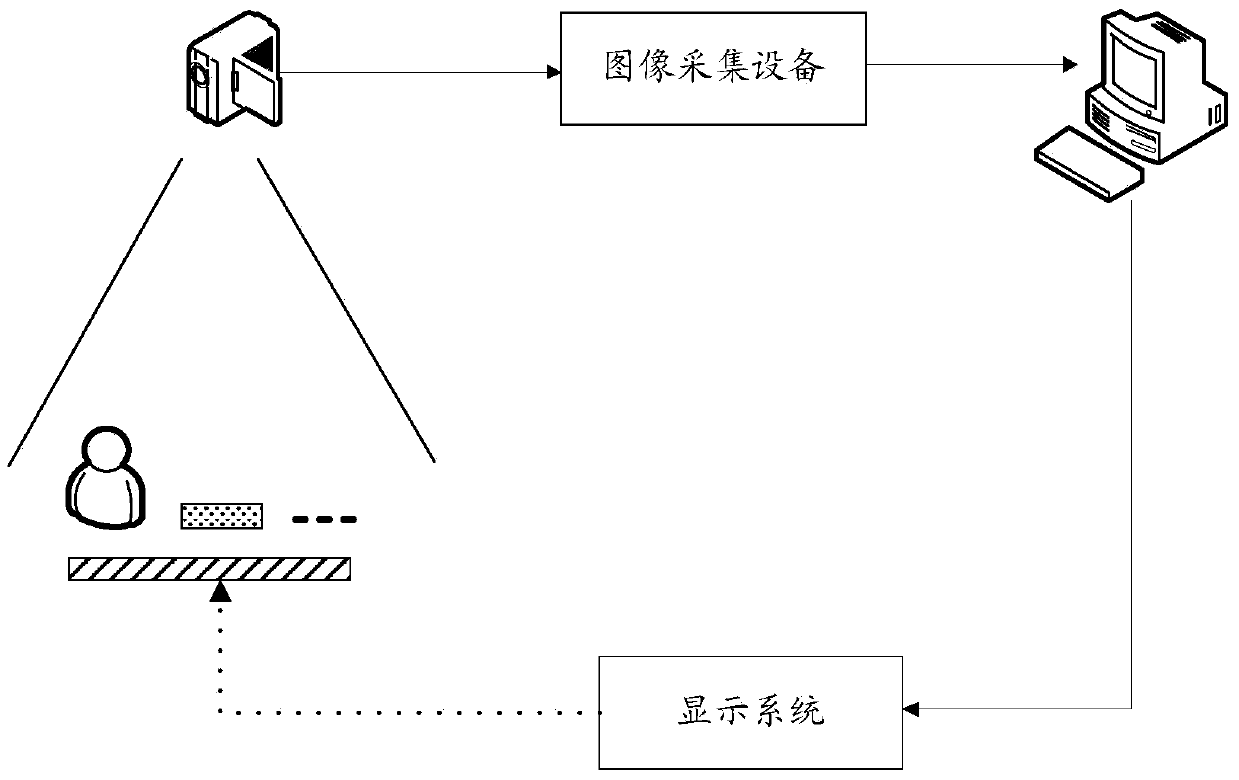

[0091] Embodiment 2, a welding operation training simulation system based on augmented reality. Combine below Figure 8 The system provided by the present invention is described in detail.

[0092] Figure 8 Among them, the system provided by the present invention includes a trajectory capture module 801 , a trajectory display module 802 , an establishment module 803 , an augmented reality display module 804 and a specific screen presentation module 805 .

[0093] Among them, the trajectory capture module 801 is mainly used to capture the spatial trajectory of the AR welding torch by adopting the monocular vision positioning method.

[0094] Specifically, the trajectory capture module 801 uses an optical sensor and a camera to determine the three-dimensional space coordinates of the AR welding torch, and uses a gyroscope to determine the posture of the AR welding torch, thereby capturing the spatial movement trajectory of the AR welding torch.

[0095] The trajectory displa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com