Manufacturing method for nitride LED assembly

A technology of light-emitting diodes and nitrides, which is applied in the direction of electrical components, semiconductor devices, circuits, etc., can solve the problems of reduced crystal quality of the P-type semiconductor layer, large damage to the light-emitting layer, and affecting luminous performance, so as to reduce the efficiencydroop effect and increase the recombination Efficiency, the effect of enhancing luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

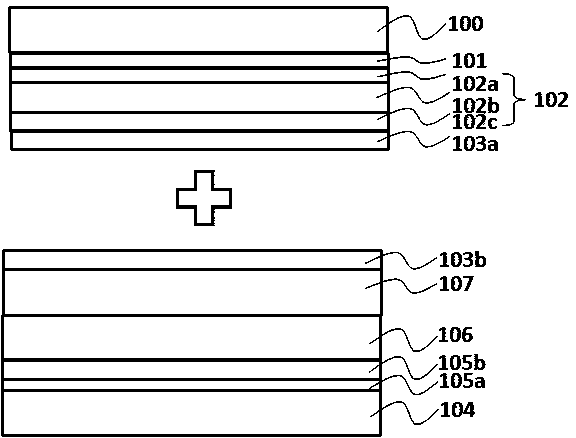

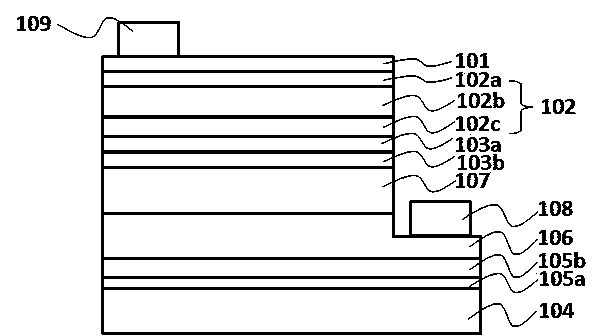

[0026] like figure 1 and 2 As shown, a method for preparing a nitride light-emitting diode assembly, the method is realized by the following steps:

[0027] (1) Provide a transition substrate 100, the transition substrate is selected from alumina single crystal (Sapphire) or SiC (6H-SiC or 4H-SiC) or Si or GaAs or GaN or a combination thereof, preferably in this embodiment Si substrate;

[0028] (2) Form a transparent conductive layer 101 on the transition substrate 100. The transparent conductive layer can be ITO, IZO, ZnO, GZO, ITO containing silicon oxide, etc., and ITO is preferred in this embodiment;

[0029] (3) Growing a P-type semiconductor layer 102 and a first GaN layer 103a sequentially on the transparent conductive layer 101, wherein the P-type semiconductor layer includes a P-type contact layer, a P-type layer and an electron blocking layer, and the first GaN layer 103a has a thickness of 1-100nm, preferably 10nm;

[0030] (4) Provide a permanent substrate 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com