A high-voltage direct current transmission system with direct current fault ride-through capability

A DC fault ride-through and high-voltage DC technology, which is applied in the direction of DC network circuit devices, AC power input conversion to DC power output, electrical components, etc., can solve problems such as restricting FBMMC engineering applications, increasing investment costs, etc., and achieve investment savings cost, reduced investment costs, and increased speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

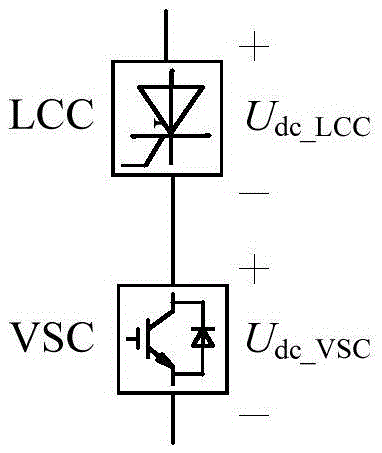

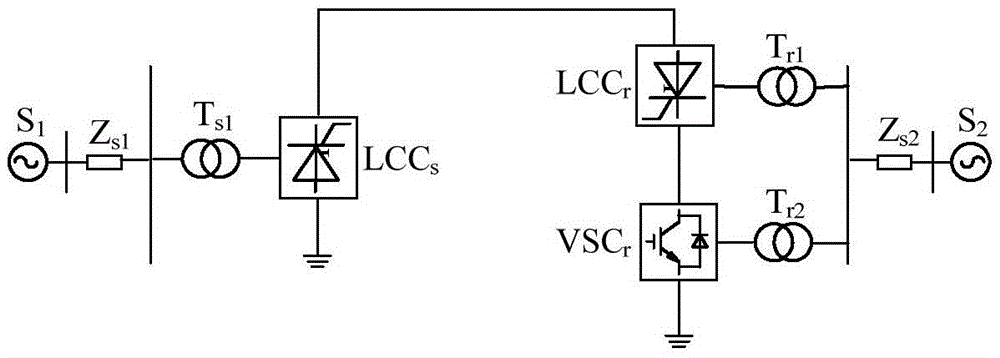

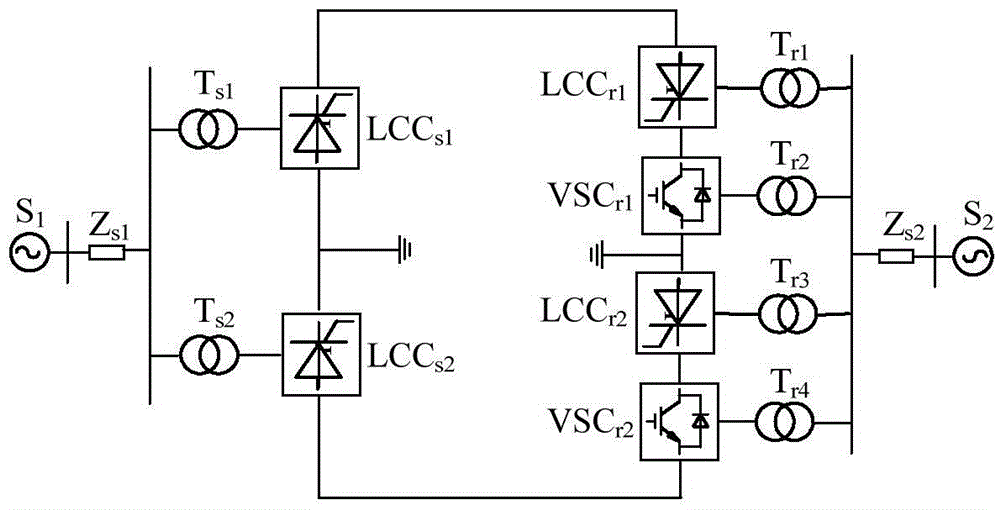

[0038] The invention provides a high-voltage direct current transmission system with DC fault ride-through capability. The high-voltage direct current transmission system includes a rectifier station, a transmission line, and an inverter station. The rectifier station and the inverter station include a converter. The converter on the rectification side The converter on the inverter side is connected through the transmission line; the converter on the rectification side includes a grid commutated converter LCC; the converter on the inverter side includes a voltage source connected in series A converter VSC and a grid-commutated converter LCC, the positive pole of the voltage source converter VSC is connected to the negative pole of the grid-commutated converter LCC.

[0039] The high-voltage overhead transmission line is a line with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com