Soluble non-dairy creamer tablet surface-treated with carbohydrate

A carbohydrate and surface treatment technology, applied in dairy products, applications, milk substitutes, etc., can solve the problems of easy damage and difficult handling of non-dairy creamer tablets

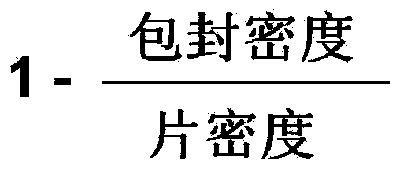

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Embodiment 1: the surface treatment of milk sheet

[0064] A carbohydrate solution was prepared for surface treatment of non-dairy creamer chips. Described carbohydrate solution is:

[0065] • A sucrose solution containing 50% dry matter sucrose.

[0066] • Maltodextrin solution containing 50% dry matter maltodextrin DE29.

[0067] Composition base powder:

[0068]

Base Powder A:

Base Powder B:

Matrix powder C:

57

51

59

vegetable fat

34

35

33

caseinate

2.5

1.4

2.3

stabilizer

2.6

2.3

1.9

Emulsifier

0.5

1

0.5

7

[0069] Table 1

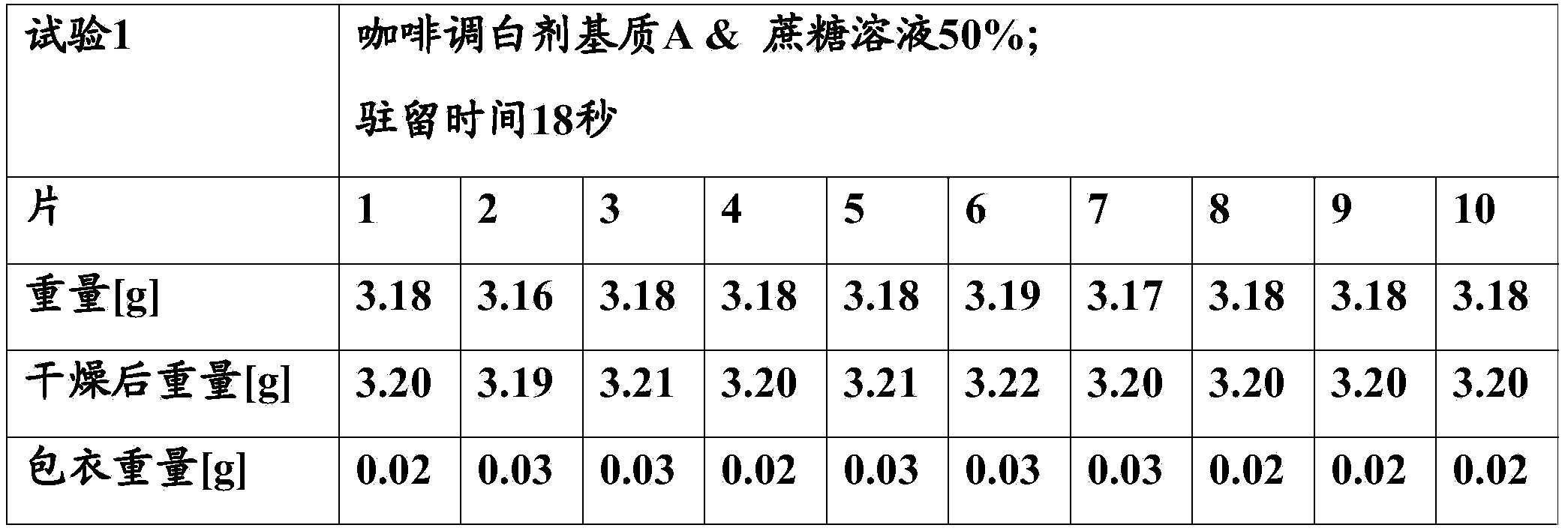

[0070] Surface Treatment of Non-Dairy Creamer Chips with Sucrose

[0071] Non-dairy creamer tablets prepared from coffee whitener base A or B (Table 1, base powder A or B) were sprayed with a sucrose solution (50% dry matter sucrose) as shown in Table 2 below.

[0072] ...

Embodiment 2

[0090] Example 2: Friability Analysis of Non-Dairy Creamer Chips Surface-Treated with Carbohydrates

[0091]The friability analysis was performed on non-dairy creamer chips surface treated with carbohydrates prepared as in Example 1, Run 2 (Table 2b). As a reference, non-dairy creamer chips that were not surface treated with carbohydrates were also analyzed for friability. Table 4 below shows the results of the friability analysis.

[0092]

[0093] Matrix powder A

[0094] Table 4

[0095] The friability is mainly perceived during handling of the tablet, ie by touch.

[0096] It can be clearly seen that the non-dairy creamer flakes that were not surface treated with carbohydrates had a high friability of 19.7%. This is in contrast to the non-dairy creamer tablets surface treated with carbohydrates which had significantly reduced friability of 8.1% and 0.4%.

Embodiment 3

[0097] Example 3: Dissolution Analysis of Non-Dairy Creamer Tablets Surface Treated with Carbohydrates

[0098] The dissolution properties of non-dairy creamer tablets surface treated with carbohydrates prepared as described below were analyzed. This analysis was performed to ensure that surface treatment with carbohydrates did not adversely affect the non-dairy creamer tablets. Table 5 below shows the results.

[0099]

[0100] table 5

[0101] It can be clearly seen that the surface treatment of the non-dairy creamer tablets with carbohydrates has no adverse effect on the dissolution properties of the non-dairy creamer tablets. This is important because non-dairy creamer tablets surface treated with carbohydrates are used in the beverage industry where the dissolution rate of the non-dairy creamer tablets is very important.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com