Environment-friendly baking-free brick and preparation method thereof

A non-burning brick, environmentally friendly technology, applied in the field of new building materials, to achieve the effect of enhancing waterproofness, enhancing wear resistance and compressive resistance, and good synergy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

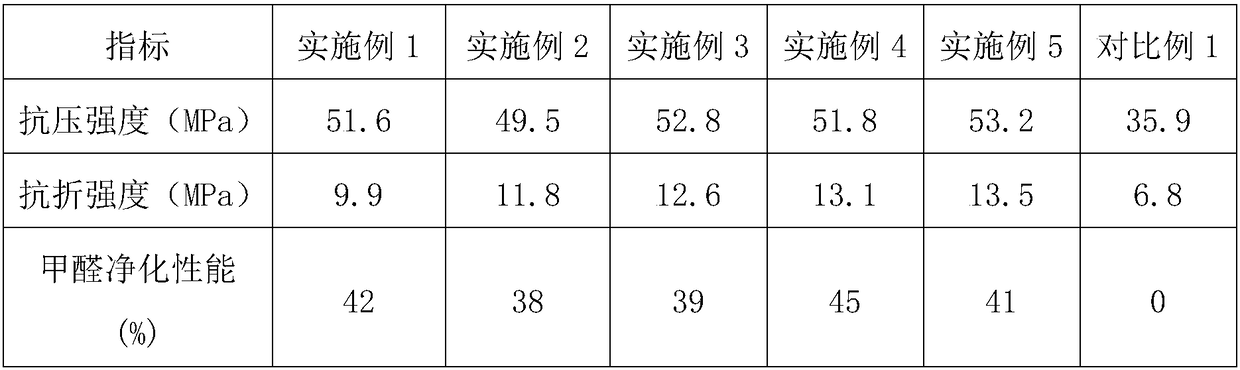

Examples

Embodiment 1

[0029] An environment-friendly non-burning brick, comprising the following raw materials in parts by weight:

[0030] 30 parts of construction waste, 10 parts of waste rock wool, 6 parts of polypropylene fiber, 8 parts of thatch root powder, 5 parts of alfalfa grass powder, 15 parts of clay, 15 parts of Portland cement, 2 parts of sodium dodecylbenzenesulfonate , 4 parts of magnesium oxide, 3 parts of zinc borate, 2 parts of polyvinylpyrrolidone, 8 parts of soybean protein adhesive, 15 parts of water glass, 1.2 parts of water reducing agent, 2.5 parts of antibacterial agent, 5 parts of latex powder and 12 parts of water;

[0031] The construction waste is waste glass, waste bricks and tiles, waste mortar or waste concrete, which are put into a crusher and crushed until the particle size is less than 1 mm.

[0032] The water reducer is calcium lignosulfonate.

[0033] The antibacterial agent is a plant antibacterial agent, and the plant antibacterial agent includes the followi...

Embodiment 2

[0045] An environment-friendly non-burning brick, comprising the following raw materials in parts by weight:

[0046] 40 parts of construction waste, 18 parts of waste rock wool, 12 parts of polypropylene fiber, 15 parts of thatch root powder, 10 parts of alfalfa grass powder, 20 parts of clay, 20 parts of Portland cement, 5 parts of sodium dodecylbenzene sulfonate , 9 parts of magnesium oxide, 6 parts of zinc borate, 5 parts of polyvinylpyrrolidone, 15 parts of soybean protein adhesive, 20 parts of water glass, 2.4 parts of water reducing agent, 3.6 parts of antibacterial agent, 10 parts of latex powder and 18 parts of water;

[0047] Construction waste is waste glass, waste bricks, waste mortar or waste concrete put into the crusher and crushed until the particle size is less than 1 mm.

[0048] The water reducer is sodium lignosulfonate.

[0049] The antibacterial agent is a plant antibacterial agent, and the plant antibacterial agent includes the following raw materials i...

Embodiment 3

[0060] An environment-friendly non-burning brick, comprising the following raw materials in parts by weight:

[0061] 32 parts of construction waste, 12 parts of waste rock wool, 8 parts of polypropylene fiber, 10 parts of thatch root powder, 6 parts of alfalfa grass powder, 17 parts of clay, 17 parts of Portland cement, 3 parts of sodium dodecylbenzenesulfonate , 5 parts of magnesium oxide, 4 parts of zinc borate, 3 parts of polyvinylpyrrolidone, 10 parts of soybean protein adhesive, 17 parts of water glass, 1.5 parts of water reducing agent, 2.9 parts of antibacterial agent, 6 parts of latex powder and 14 parts of water ;

[0062] Construction waste is waste glass, waste bricks, waste mortar or waste concrete put into the crusher and crushed until the particle size is less than 1 mm.

[0063] The water reducer is magnesium lignosulfonate.

[0064] The antibacterial agent is a plant antibacterial agent, and the plant antibacterial agent includes the following raw materials ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com