Resin-coated aluminum plate, and outer container for electronic components

A technology of resin and aluminum plate, which is applied in the direction of capacitor parts, capacitor case/packaging, synthetic resin layered products, etc., which can solve the problems of poor elongation, non-elongation of the film, intolerance to use, etc., and achieve improved alcohol resistance , Short semi-crystallization time and easy crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3、 comparative example 1

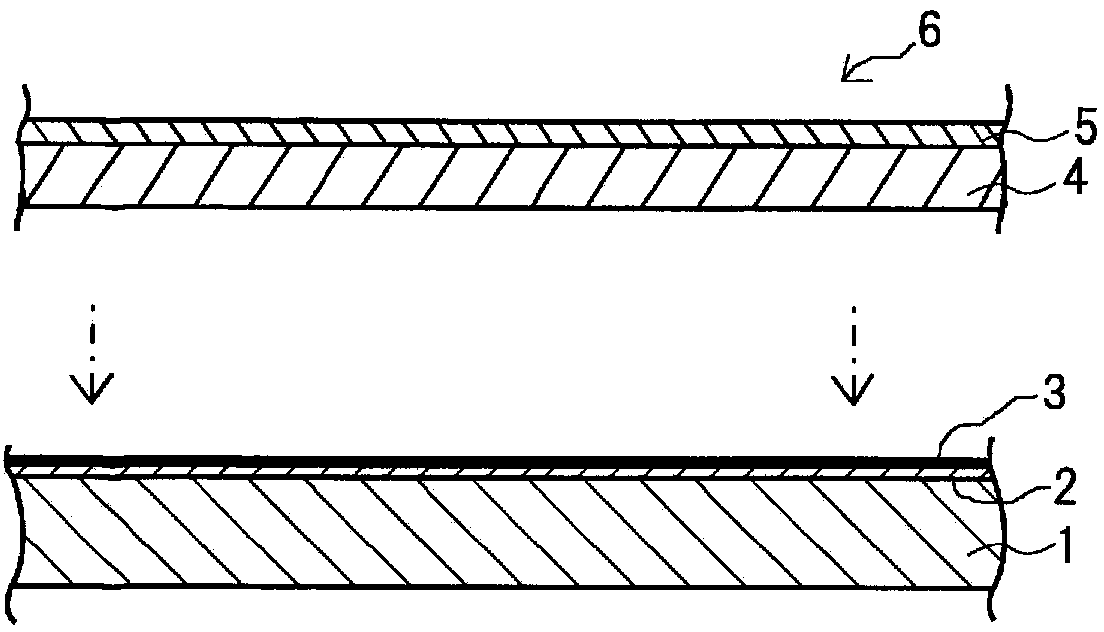

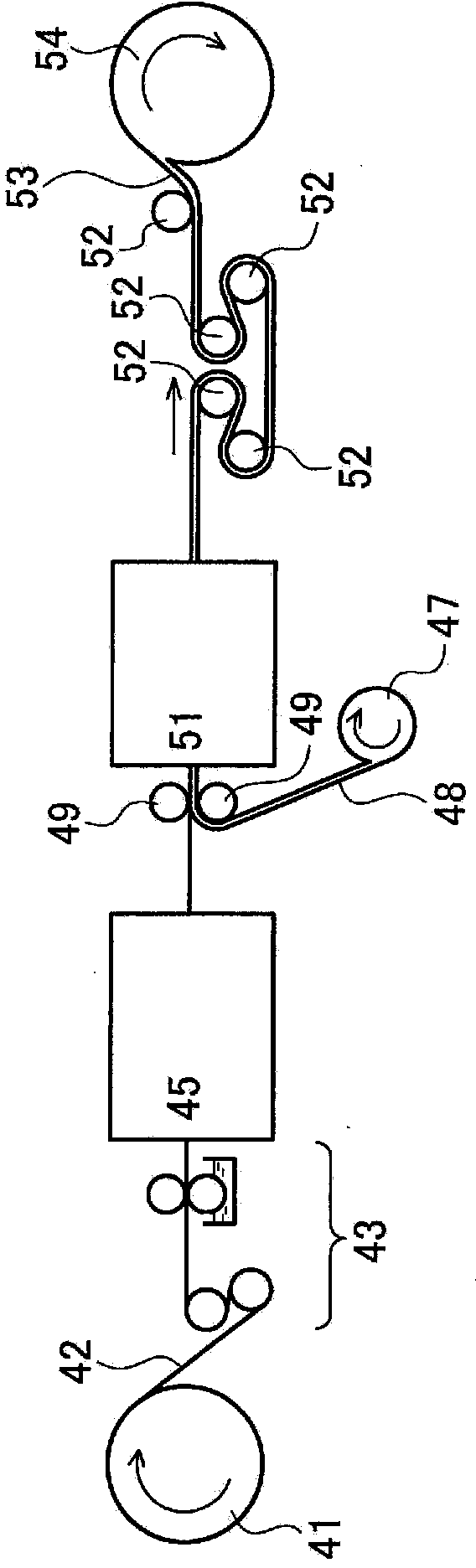

[0178] The resin pellets obtained by mixing the polyamide resin layer ratios shown in Tables 1 and 2 were extruded using an extrusion molding machine equipped with a T-die to produce a polyamide resin film with a thickness of 20 μm. A resin-coated aluminum plate was obtained by instantaneously heating and pressing the obtained polyamide-based resin film on a heated non-porous anodized aluminum plate at 260° C. with a pair of pressure rolls to integrally laminate it.

[0179] Tables 1 and 2 show the evaluation results of the polyamide-based resin film and the resin-coated aluminum plate.

Embodiment 4~11

[0180] [Examples 4-11, Comparative Examples 2-5, 7]

[0181] Two-layer co-extrusion was carried out using an extrusion molding machine equipped with a T-die using the resin pellets obtained by mixing the polyamide-based resin layer ratios shown in Tables 1 and 2 and the above-mentioned nylon 6-layer resin pellets. Molding was performed to produce a laminated film of a polyamide-based resin film with a thickness of 20 μm and a nylon 6 film with a thickness of 2 μm.

[0182]This laminated film was integrally laminated with a non-porous anodized aluminum plate in the same manner as in Example 1 to obtain a resin-coated aluminum plate.

[0183] Tables 1 and 2 show the evaluation results of the above laminated film (evaluation of the nylon 6 film side) and the resin-coated aluminum plate.

reference example 1

[0187] A resin-coated aluminum plate was produced in the same manner as in Example 5 except that the thickness of the nylon 6 film was 5 μm, and the evaluation results are shown in Table 2.

[0188] It should be noted that the DSC measurement charts of the polyamide-based resin films of Examples 1, 2, 8 and Comparative Example 1 in the above are shown in Figure 4 , the half-crystallization time determination plot is shown in Figure 5 .

[0189] Table 1

[0190]

[0191] Table 2

[0192]

[0193] It can be seen from Tables 1 and 2 that the surface of the aluminum plate is subjected to non-porous anodic oxidation treatment, and a specified amount of crystallization accelerator is added to the polyamide resin layer to make the crystallization initiation temperature range from 177 to 200°C, so that the semi-crystalline If the time is 2 minutes or less, a resin-coated aluminum plate can be obtained that does not have the problem of deterioration in appearance quality due...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com