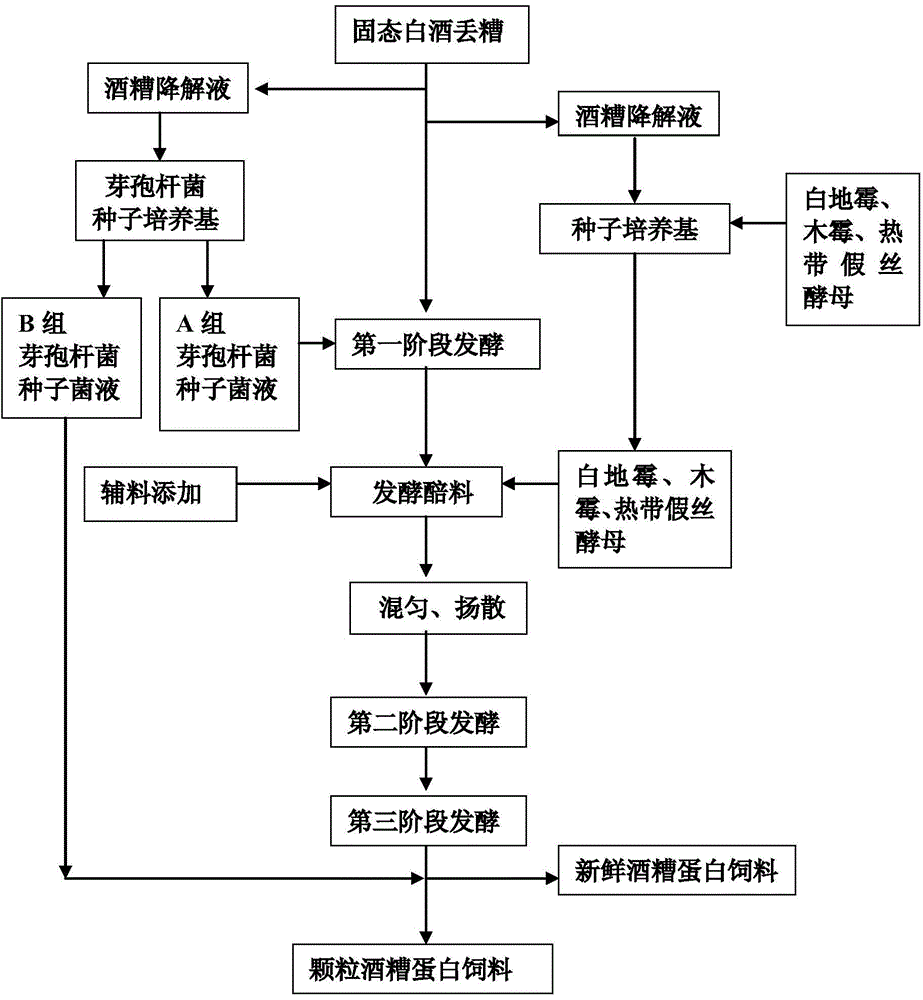

Method for preparing distillers' grain protein feed through three-stage mixed bacterium solid state fermentation

A distiller's grain protein feed and solid-state fermentation technology, applied in animal feed, animal feed, applications, etc., can solve the problems of crude protein content, low digestible energy and metabolizable energy, low added value of feed, and affecting the effective utilization of nutrients, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] (1) The first stage of solid-state fermentation with mixed bacteria: use 100kg of fresh discarded grains as the substrate, adjust the pH value to 6.5 with lime, add 10kg of group A Bacillus combined seed bacterial liquid, mix evenly and put it into sacks, stack fermentation and naturally heat up to 63°C Finally, pour out the sacks and spread the production site to cool down to 45°C, then accumulate and ferment and raise the temperature to 60°C, maintain the fermentation temperature between 55°C and 60°C by turning over, stacking, and spread out, the fermentation time is 2 days, and the product is distiller's grains. .

[0063] (2) The second stage of solid-state fermentation with mixed bacteria: add 16kg of pagoda tree leaf powder, 11.1kg of poplar leaf powder by weight, 11kg of bran, and 0.16kg of dipotassium hydrogen phosphate to the 110kg of distiller's grains obtained after the first stage of fermentation , 0.11kg magnesium sulfate, 2.2kg ammonium sulfate, at the sa...

Embodiment 2

[0068] (1) The first stage of solid-state fermentation with mixed bacteria: use 100kg of fresh discarded grains as the substrate, adjust the pH value to 6.5 with lime, add 10kg of group A Bacillus combined seed bacteria liquid, mix evenly and put it into sacks, pile up and ferment and naturally heat up to 65°C Finally, pour out the sacks and spread the production site to lower the temperature by 45°C, then pile up and ferment and raise the temperature to 60°C, maintain the fermentation temperature between 55°C and 60°C by turning over, stacking, and spread out, and the fermentation time is 3 days. The product is distiller's grains.

[0069] (2) The second stage of solid-state fermentation with mixed bacteria: Weigh 100kg of distiller's grains fermented grains after the first stage of fermentation, add 18kg of pagoda tree leaf powder, 10kg of poplar leaf powder, 12kg of bran, 0.15kg of dipotassium hydrogen phosphate, and 0.1kg of sulfuric acid Magnesium, 2kg of ammonium sulfate,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com