Preparation method of starch-based zinc-rich nutrition enhancer

A nutritional enhancer, starch-based technology, applied in the field of preparation of starch-based zinc-rich nutritional enhancer, can solve the problems of zinc ions falling off easily, achieve low cost, high production efficiency, and solve the effect of easy falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

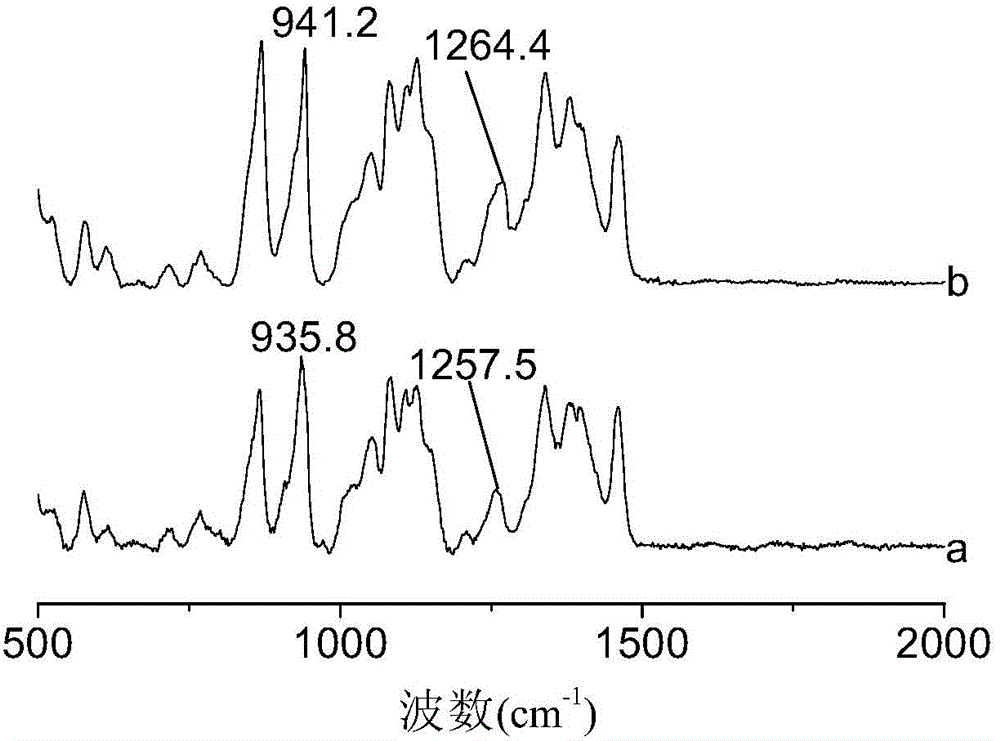

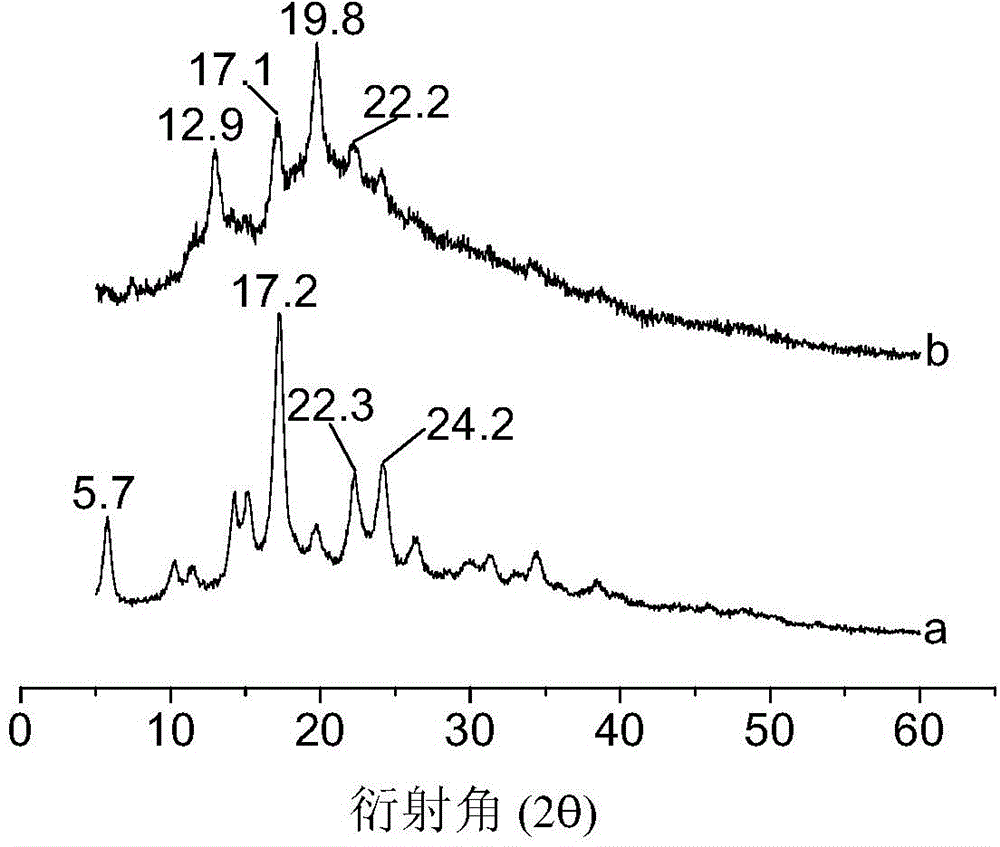

Method used

Image

Examples

Embodiment 1

[0022] The first step potato starch (50g, dry basis) is made into the starch milk that the mass percent concentration is 5% with disodium hydrogen phosphate-sodium dihydrogen phosphate buffer solution, and adjusts pH to 4.5, is placed in airtight container at 95 ℃ Stir and gelatinize for 30min; after the gelatinization is completed, cool the gelatinized liquid, add pullulanase (OPTIMAX L-1000, Genencor Bioengineering Co., Ltd.), and the dosage is to add pullulanase 10u per gram of dry starch, Stir and react at 60°C for 3 hours; adjust the pH to 6.0, add medium temperature α-amylase (CLARASE L, Genencor Bioengineering Co., Ltd.), the dosage is 2u per gram of dry starch, stir and react at 60°C for 5 minutes; adjust pH to 2.5 and keep for 10 minutes to inactivate the enzyme to obtain amylose solution;

[0023] In the second step, the temperature of the amylose solution obtained in step (1) is adjusted to 80° C., 100 mL of 1 mol / L zinc chloride solution is added to the above solut...

Embodiment 2

[0032]The first step tapioca starch (50g, dry base) is made into the starch milk that mass percent concentration is 8% with disodium hydrogen phosphate-sodium dihydrogen phosphate buffer solution, and adjusts pH to 5.0, is placed in airtight container at 96 ℃ Stir and gelatinize for 40min; after the gelatinization is completed, cool the gelatinized liquid, add pullulanase (OPTIMAX L-1000, Genencor Bioengineering Co., Ltd.), and the dosage is to add 30u of pullulanase per gram of dry starch. Stir and react at 55°C for 1 hour; adjust the pH to 6.5, add high temperature resistant α-amylase (Liquozyme Supra, Novozymes company), the dosage is 1u per gram of dry starch, stir and react at 95°C for 10 minutes; adjust the pH to 3.0 and Keep for 15 minutes to inactivate the enzyme to obtain amylose solution;

[0033] In the second step, adjust the temperature of the amylose solution obtained in step (1) to 50° C., add 50 mL of 2 mol / L zinc sulfate solution to the above solution, and adj...

Embodiment 3

[0036] The first step waxy cornstarch (50g, dry basis) is made into the starch milk that mass percent concentration is 10% with disodium hydrogen phosphate-sodium dihydrogen phosphate buffer solution, and adjusts pH to 6.5, is placed in airtight container at 99 Stir and gelatinize at ℃ for 50 min; after the gelatinization is completed, cool the gelatinized liquid, add isoamylase (Pseudomonas sp, Sigma-Aldrich company), the dosage is 20 u of isoamylase per gram of dry starch, and stir the reaction at 50°C 2 hours; adjust the pH to 7.0, add high temperature resistant α-amylase (Liquozyme Supra, Novozymes company), the dosage is 10u per gram of dry starch, stir and react at 110°C for 1 minute; adjust the pH to 2.5 and keep it for 10 minutes to kill the enzyme , to obtain amylose solution;

[0037] In the second step, the temperature of the amylose solution obtained in step (1) is adjusted to 60° C., 80 mL of 1.5 mol / L zinc acetate solution is added to the above solution, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com