Method for manufacturing dried sea-cucumbers

A processing method and technology for drying sea cucumbers, applied in the field of food processing, can solve the problems of unsatisfactory taste of sea cucumbers, loss of nutritional components of sea cucumbers, etc., and achieve the effects of shortening processing time, good elasticity of meat and thorough cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

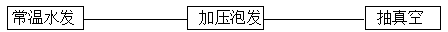

[0026] A kind of processing method of dried sea cucumber of the present invention, its processing step comprises:

[0027] a. Water fermentation at room temperature, put 100g of dried sea cucumber prepared in advance into pure water at room temperature at 25°C, and the time required is 10 hours. After the sea cucumber body softens, clean the skin and belly of the sea cucumber body;

[0028] b. Pressurized foaming. Put the cleaned sea cucumbers into a sealed container with normal temperature pure water for pressurized foaming. The time for pressurized foaming is 40 hours, and the pressure of pressurized foaming is 0.25Mpa. During the foaming process, replace the normal temperature pure water once every 6 hours;

[0029] c. Vacuumize, put the sea cucumber soaked and sent out in step b into a pure water airtight container and carry out low-pressure vacuum treatment to obtain 950g of processed water-made sea cucumber.

Embodiment 2

[0031] A kind of processing method of dried sea cucumber of the present invention, its processing step comprises:

[0032] a. Water fermentation at room temperature, put 150g of dried sea cucumbers prepared in advance into pure water at room temperature at 30°C, and the time required is 12 hours. After the sea cucumber body is softened, clean the skin and belly of the sea cucumber body;

[0033] b. Pressurized foaming. Put the cleaned sea cucumbers into a sealed container with normal temperature pure water for pressurized foaming. The time for pressurized foaming is 50 hours, and the pressure of pressurized foaming is 0.3Mpa. During the foaming process, replace the normal temperature pure water once every 7 hours;

[0034] c. Vacuumize, put the sea cucumber soaked in step b into a pure water airtight container and carry out low-pressure vacuum treatment to obtain 1300g of processed water-emitted sea cucumber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com