A Welding Method for Oscillating Arc Narrow Gap Single-sided Welding and Double-sided Forming

A single-sided welding double-sided, welding method technology, applied in arc welding equipment, welding equipment, workpiece edge parts and other directions, can solve the problems of low welding efficiency, expensive welding equipment, etc., to achieve high welding efficiency, low implementation cost, welding The effect of low heat input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

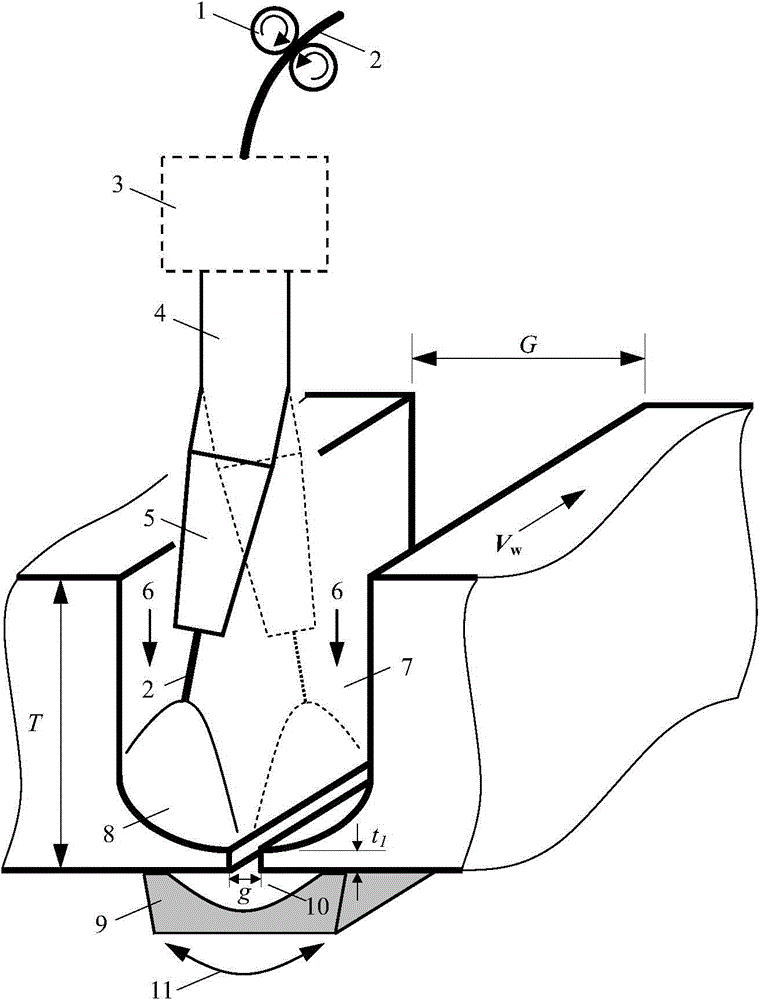

Method used

Image

Examples

Embodiment 1

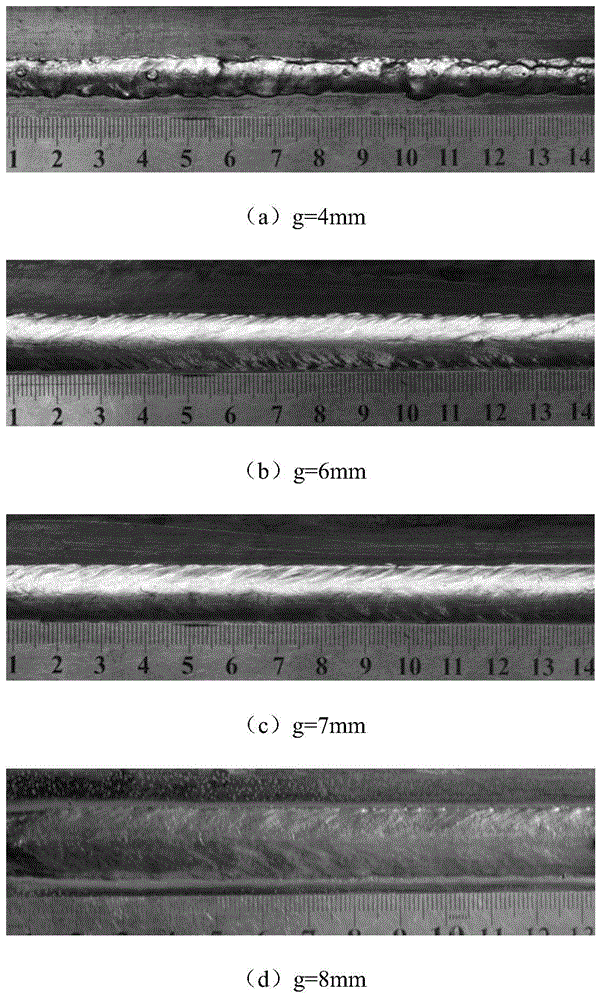

[0042] figure 2 Shown is the groove gap G = 12mm, and the back weld shape after rooting welding at different root gaps g, where, figure 2 (a) is the back weld formation when the root gap g=4mm, at this time the blunt edge thickness t 1 = 2mm, the width of the forming groove 10 of the liner 9 is 8mm, the arc shaking frequency set corresponding to rooting welding is 0.5Hz, the arc shaking amplitude is 35°, the arc stay time on the side wall is 200ms, and the average welding current is 220A, The average arc voltage is 26V, the welding speed is V w 13.5cm / min; figure 2 (b) is the back weld formation when the root gap g=6mm, at this time the blunt edge thickness t 1 = 1.5mm, the width of the forming groove 10 of the liner 9 is 10mm, the corresponding arc shaking frequency is 1.0Hz, the arc shaking amplitude is 66°, the residence time of the arc on the side wall is 150ms, and the average welding current is 200A , the average arc voltage is 24V, the welding speed is V w 10.5c...

Embodiment 2

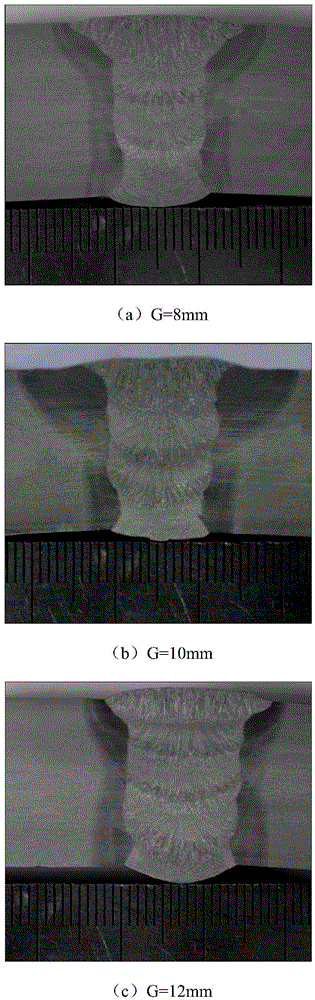

[0045] image 3 Shown is a macroscopic photo of the shaking arc narrow gap single-sided welding and double-sided forming welded joints of 20mm thick ordinary strength steel at different groove gaps G. for pure CO 2 gas.

[0046] in, image 3 (a) is a macroscopic photo of the shaking arc narrow gap single-sided welding and double-sided forming welding joint when the groove gap G=8mm. At this time, the root gap g=6mm and the blunt edge thickness t 1 =1mm, the width of the forming groove 10 of the liner 9 is 10mm, the corresponding arc shaking frequency set for root welding is 1.0Hz, the arc shaking amplitude is 66°, the arc stay time on the side wall is 150ms, and the average welding current is 180A , the average arc voltage is 22V, the welding speed is V w 9.5cm / min; the arc shaking frequency set for filling welding is 3.5Hz, the arc shaking amplitude is 50°, the arc stays on the side wall for 40ms, the average welding current is 260A, the average arc voltage is 26.5V, and ...

Embodiment 3

[0051] Figure 4 Shown is a macroscopic photo of the oscillating arc narrow gap single-sided welding and double-sided forming welded joints of high-strength steel with a thickness of 50 mm at different groove gaps G. Designed for the root gap g = 7mm, blunt edge thickness t 1 =1mm, and all use the liner 9 that the width of the forming groove 10 is 14mm, and the shielding gas 6 is that the composition is Ar80%+CO 2 of mixed gas.

[0052] in, Figure 4 (a) is a macroscopic photo of the shaking arc narrow gap single-sided welding and double-sided forming welding joint when the groove gap G=12mm. The corresponding arc shaking frequency is set to 1.5Hz and the arc shaking amplitude is 76° for backing welding. The residence time of the arc on the side wall is 100ms, the average welding current is 180A, the average arc voltage is 22V, and the welding speed is V w 9.5cm / min; the arc shaking frequency set for filling welding is 2.8Hz, the arc shaking amplitude is 70°, the arc stay ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com