Environment-friendly light fireproof plate preparation technology and device

A preparation process and technology of fireproof board, which are applied in the field of preparation process and equipment of environment-friendly impact-resistant light-weight fireproof board, can solve the problems of easy breakage, unreasonable use of materials, low safety performance, etc., and achieve the effect of strong impact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

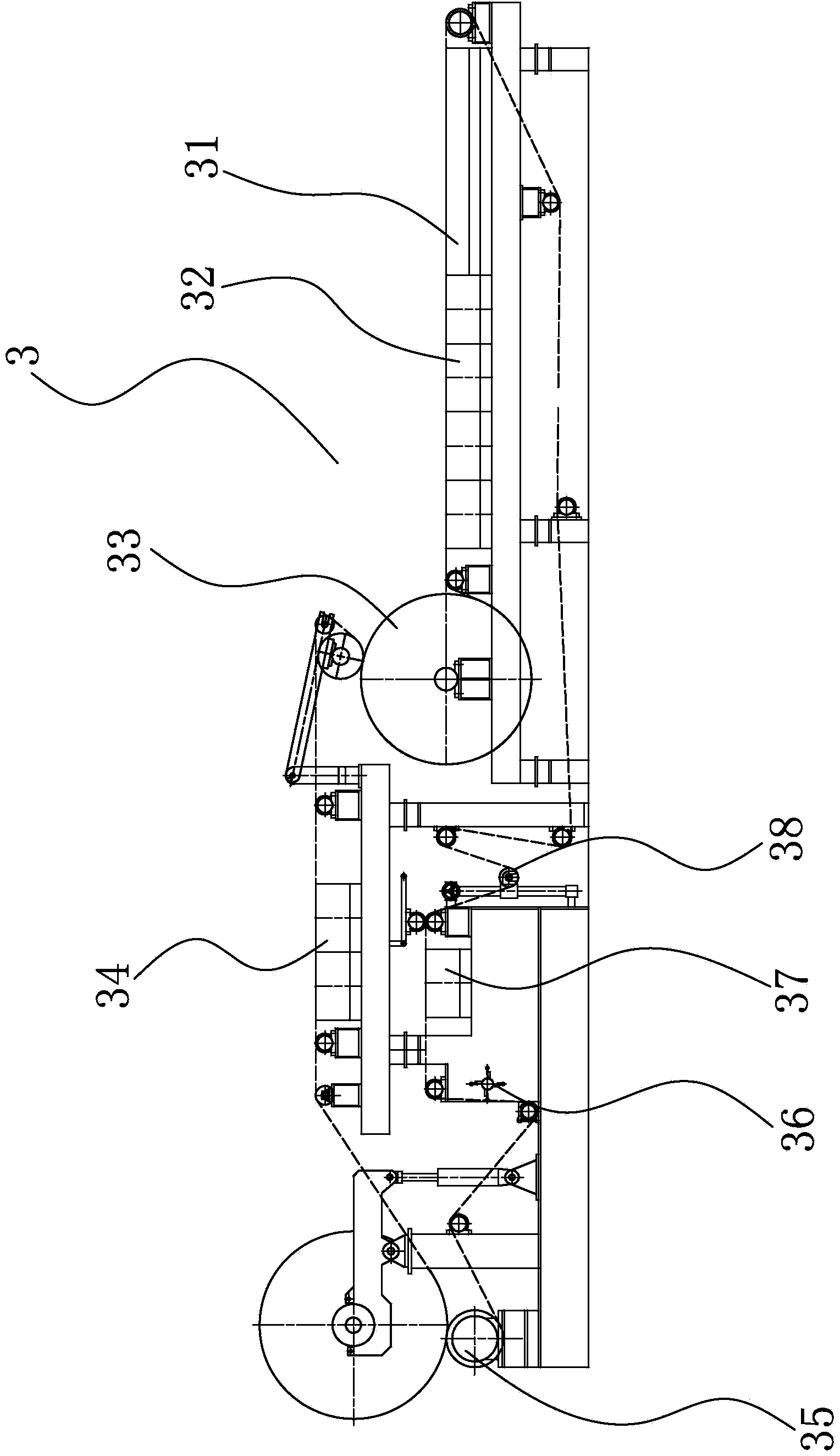

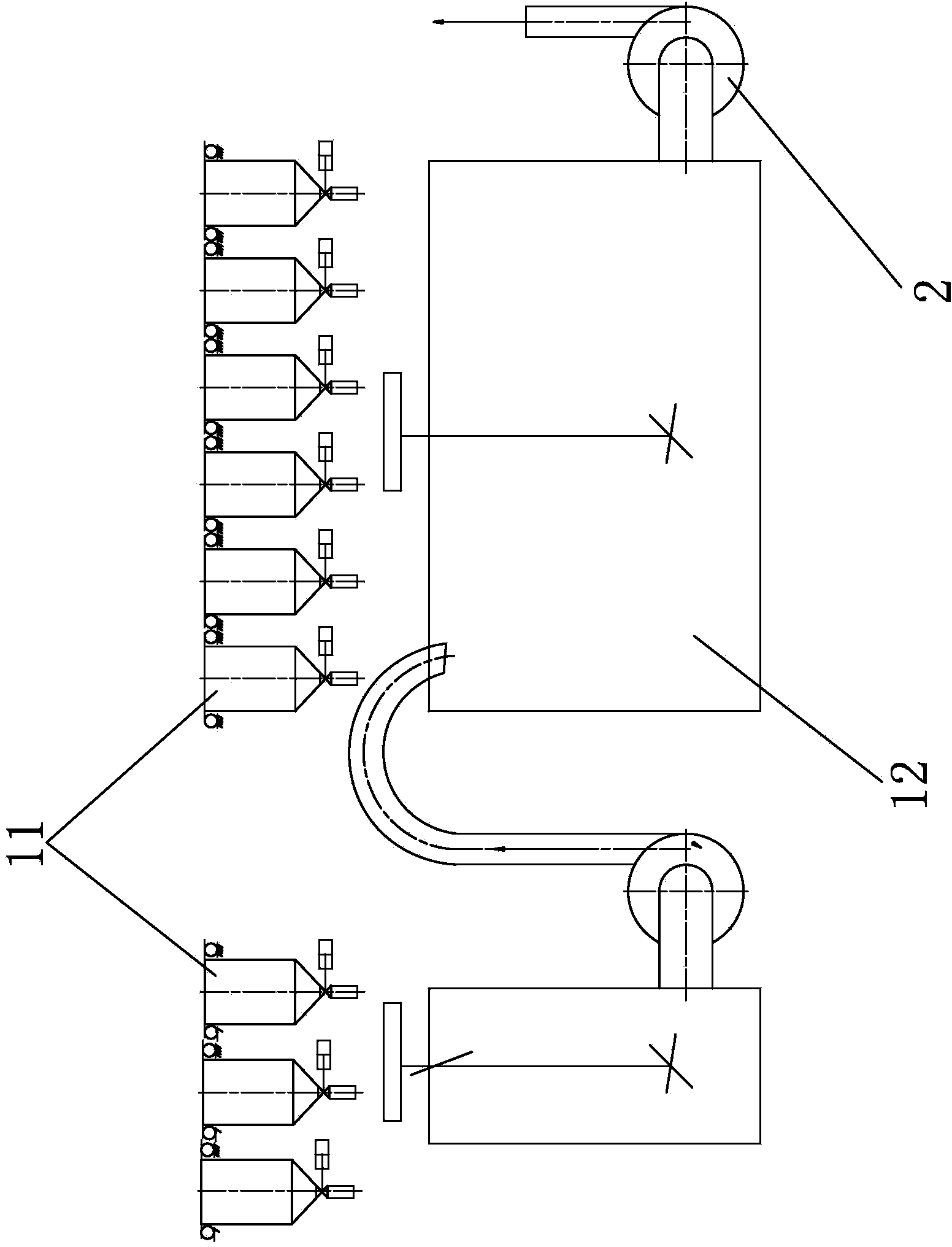

[0030] The concept, specific structure and technical effects of the present invention will be clearly and completely described below in conjunction with the embodiments and accompanying drawings, so as to fully understand the purpose, features and effects of the present invention.

[0031] A preparation process of an environment-friendly lightweight fireproof board is:

[0032] 1) Mix and stir the raw materials and auxiliary materials according to the proportion to obtain the slurry;

[0033] 2) Coat the slurry on the conveyor belt, send it to the dehydration forming mechanism for dehydration and plate forming, and obtain the slab with the mold;

[0034] 3) After the slab with the mold is cut and trimmed, it is sent to the resting area for resting;

[0035] 4) Demould the slabs after resting, and then use steam for high-temperature and high-pressure curing to obtain semi-finished products;

[0036] 5) The semi-finished product can be used directly or further processed after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com