New method for applying lithium bromide refrigerating device in nitrogenous fertilizer production

A refrigeration device, lithium bromide technology, applied in refrigerators, refrigeration and liquefaction, energy industry and other directions, can solve the problems of high production cost and large power consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

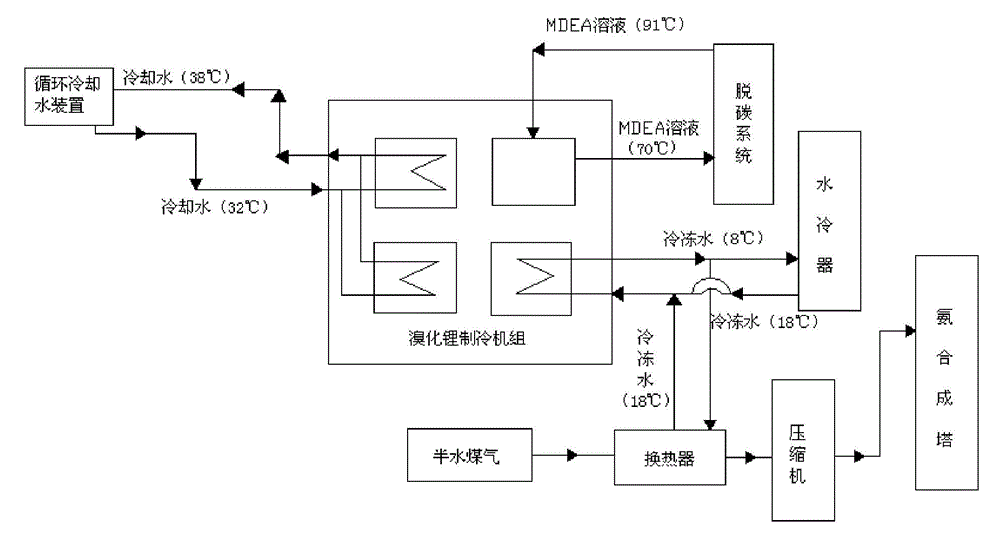

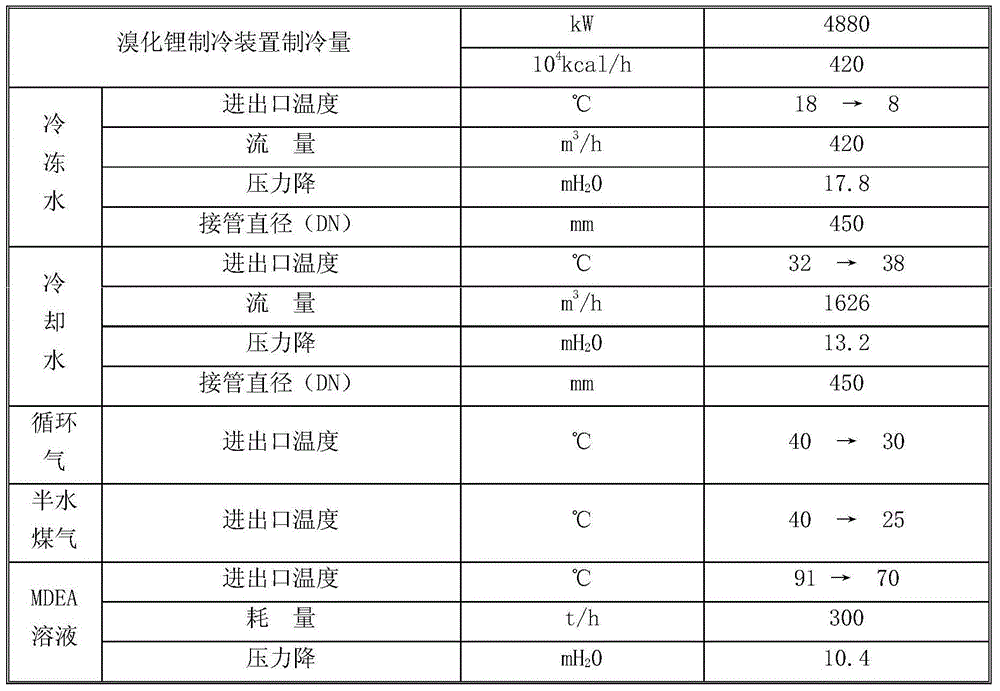

[0024] In the nitrogen fertilizer industry, lithium bromide refrigeration must be used to obtain frozen water. Most of the heat sources are low-grade steam or steam condensate, high-temperature hot water and other low-grade heat sources for lithium bromide refrigeration. However, the above heat sources have basically been used up after the company strengthened energy management. It has become a profit for the company to increase revenue and reduce expenditure. If the above-mentioned heat source is deliberately used for lithium bromide refrigeration, the income of the enterprise will be reduced and the cost of lithium bromide refrigeration will be increased.

[0025] The inventor has found in a large number of practices that there is a heat source in the MDEA decarburization process of nitrogen fertilizer production, which is MDEA hot solution. Its function is to regenerate and emit carbon dioxide after the MDEA decarburization section absorbs carbon dioxide. Release carbon dio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com