Preparation method for antimony-free polyester for bottles

A technology for bottles and polyester, applied in the field of preparation of polyethylene terephthalate (PET) materials, which can solve the problems of antimony element precipitation, high acetaldehyde content, obvious side reactions, etc., to reduce production capacity Consumption, shorten the process flow, save the effect of solid phase polycondensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

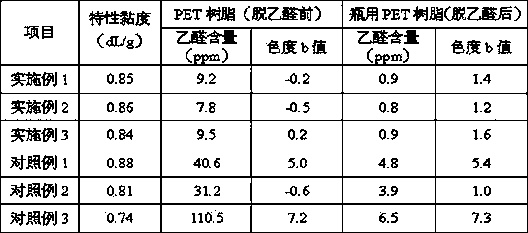

Examples

Embodiment 1

[0026] The molar ratio of PTA to EG is 1:1.3, add 2.0% IPA and 0.8% DEG by weight of PTA, add Ti-Mg catalyst equivalent to 10 ppm of PTA weight in terms of titanium element, and 1.8 ppm of blue toner, Carry out esterification reaction, the temperature of the esterification reaction is 240~250°C, the relative pressure is 0~0.2MPa, the by-product water is released, and ethylene terephthalate (BHET) and its oligomers are generated; when the esterification conversion rate reaches After 97%, vacuumize for polycondensation, add 9ppm of phosphoric acid in terms of phosphorus and 30ppm of antioxidant 1010, polycondensation temperature 255~265℃, absolute pressure 0.1~20kPa; when the intrinsic viscosity reaches about 0.35dL / g, the PET base The melt is distributed to the upper ends of the vertically downward falling film tubes in the liquid phase thickening reactor, and then slides down by gravity to form a film on the outer wall of the tube for polycondensation reaction. The falling film...

Embodiment 2

[0028] The ratio of raw materials and esterification are the same as in Example 1; when the conversion rate of esterification reaches 97%, vacuumize for polycondensation, the polycondensation temperature is 250~260°C, and the absolute pressure is 0.1~20kPa; when the intrinsic viscosity reaches about 0.25dL / g, The PET basic melt is transported to the first liquid phase thickening reactor for falling film reaction. The falling film reaction temperature is 255~265°C, the absolute pressure is 50~200Pa, and the PET basic melt flow rate of each falling film tube is 20kg / hour. The intrinsic viscosity of the melt discharged from the first liquid phase thickening reactor is about 0.50dL / g, and then transported to the second liquid phase thickening reactor for falling film reaction. The falling film reaction temperature is 255~265°C and the absolute pressure is 25~ 150Pa, the basic melt flow rate of PET in each falling film tube is 15kg / hour, and the melt will converge to the bottom of t...

Embodiment 3

[0030] The catalyst was changed to C-94 (Acordis product of Germany), and the addition amount was equivalent to 10 ppm of PTA weight in terms of titanium element, and the rest were the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com