Non-phosphorus sulfur-free chloride-free ashless lubricating oil

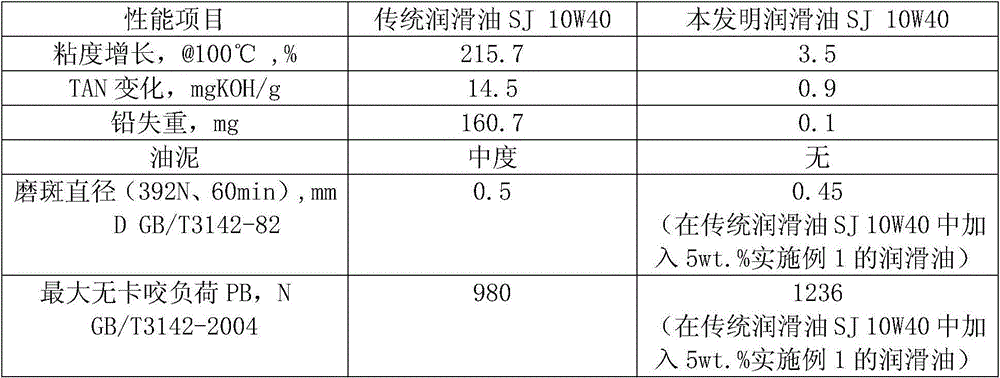

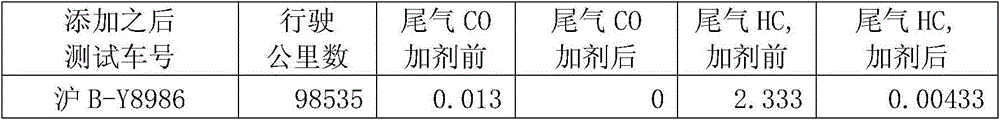

A lubricating oil and ricinoleic acid technology, which is applied in the field of energy-saving gasoline additives, can solve the problems of automobile three-way catalytic converter poisoning, non-biodegradable, metal corrosion, etc., and achieve reduced friction, strong film-forming ability, and improved sealing The effect of sex and compression ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

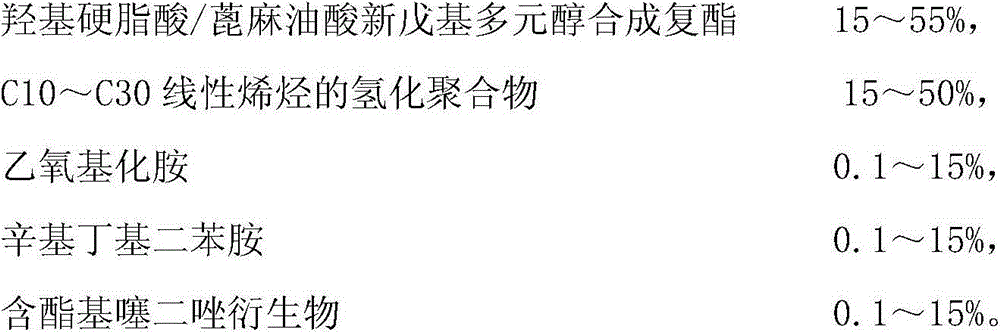

[0035] This embodiment relates to a phosphorus-free, sulfur-free, chlorine-free and ash-free lubricating oil, and the specific preparation includes the following steps:

[0036] 1.1 Preparation of hydroxystearic acid / ricinoleic acid neopentyl polyol synthetic complex ester

[0037] R-O-SO 3 H (R is a C20 straight-chain alkyl) as a catalyst, in the presence of nitrogen, in the presence of an emulsifier, a mixture of hydroxystearic acid and ricinoleic acid, and pentaerythritol as a reaction raw material, the molar ratio of acid to alcohol 3: 1, the amount of catalyst is 0.1% of the total mass of the reaction material, polyol: emulsifier molar ratio is about 1: 0.01, under the condition of 60 ℃, the water is cut off, and the esterification reaction is distilled for 48 hours to remove untreated The reacted fatty acid is the product of polyalcohol synthesis complex ester. This esterification reaction is carried out in a batch type reactor. The emulsifier is a random copolymer of...

Embodiment 2

[0042]This embodiment relates to a phosphorus-free, sulfur-free, chlorine-free and ash-free lubricating oil, and the specific preparation includes the following steps:

[0043] 2.1 Preparation of hydroxystearic acid / ricinoleic acid neopentyl polyol synthetic compound ester

[0044] R-O-SO 3 H (R is a C30 straight-chain alkyl) as a catalyst, in the presence of nitrogen, in the presence of an emulsifier, a mixture of hydroxystearic acid and ricinoleic acid, and pentaerythritol polymer as a reaction raw material, acid and alcohol The molar ratio is 10: 1, the catalyst consumption is 5% of the total mass of the reaction material, and the polyol: emulsifier molar ratio is about 1: 1. Under the condition of 120°C, the water is cut off, and the esterification reaction is distilled in 1 hour. The unreacted fatty acid is removed to obtain the product polyol synthetic complex ester. This esterification reaction is carried out in a batch type reactor. The emulsifier is a random copoly...

Embodiment 3

[0048] This embodiment relates to a phosphorus-free, sulfur-free, chlorine-free and ash-free lubricating oil, and the specific preparation includes the following steps:

[0049] 3.1 Preparation of hydroxystearic acid / ricinoleic acid neopentyl polyol synthetic complex ester

[0050] R-O-SO 3 H (R is a C24 straight-chain alkyl group) as a catalyst, in the presence of nitrogen, in the presence of an emulsifier, with a mixture of hydroxystearic acid and ricinoleic acid, and pentaerythritol polymer as a reaction raw material, acid and alcohol The molar ratio is 6: 1, the catalyst consumption is 2.5% of the total mass of the reaction material, polyhydric alcohol: emulsifier molar ratio is about 1: 0.5, under the condition of 100 ℃, the water is cut off, and the esterification reaction is distilled in 16 hours. The unreacted fatty acid is removed to obtain the product polyol synthetic complex ester. This esterification reaction is carried out in a batch type reactor. The emulsifie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com