Preparation method of heat-resistant sewing thread

A sewing thread and heat-resistant technology, applied in the direction of fiber type, wear-resistant fiber, rayon manufacturing, etc., can solve the problems of poor heat resistance and wear resistance, achieve good wear resistance, good impact recovery, The effect of good comprehensive wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

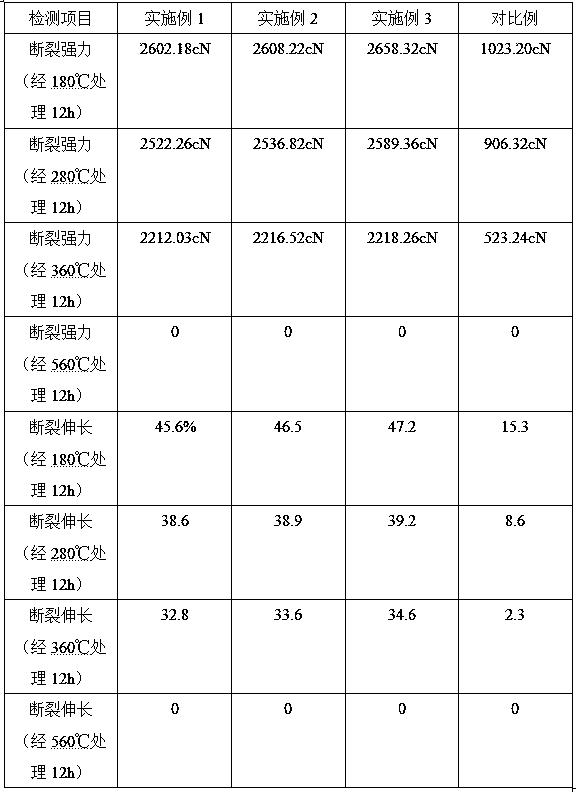

Examples

Embodiment 1

[0036] Take oxidized polyethylene wax, isomerized fatty alcohol polyoxyethylene ether, nonylphenol polyoxyethylene ether, ethylene glycol, sodium hydroxide, deionized water, and combine oxidized polyethylene wax, isomerized fatty alcohol polyoxyethylene ether, Nonylphenol polyoxyethylene ether, ethylene glycol, sodium hydroxide and deionized water are mixed, emulsified, and cooled to room temperature to obtain a microemulsion; the polyether ether ketone resin is vacuum dried to obtain a pretreated resin , The microemulsion and the pretreatment resin are mixed and placed in a twin-screw extruder to melt, extrude and granulate to obtain composite particles. The composite particles are dried to obtain spinning raw materials, and the spinning raw materials are melt-spinned. Obtain composite fiber; twist composite fiber and polytetrafluoroethylene fiber to form a blank wire; melt and stir the polyphenylene sulfide resin to obtain a melt, and immerse the blank wire in the melt for 1 m...

Embodiment 2

[0038] Take oxidized polyethylene wax, isomerized fatty alcohol polyoxyethylene ether, nonylphenol polyoxyethylene ether, ethylene glycol, sodium hydroxide, deionized water, and combine oxidized polyethylene wax, isomerized fatty alcohol polyoxyethylene ether, Nonylphenol polyoxyethylene ether, ethylene glycol, sodium hydroxide and deionized water are mixed, emulsified, and cooled to room temperature to obtain a microemulsion; the polyether ether ketone resin is vacuum dried to obtain a pretreated resin , The microemulsion and the pretreatment resin are mixed and placed in a twin-screw extruder to melt, extrude and granulate to obtain composite particles. The composite particles are dried to obtain spinning raw materials, and the spinning raw materials are melt-spinned. To obtain composite fiber; the composite fiber and polytetrafluoroethylene fiber are twisted to form a blank wire; the polyphenylene sulfide resin is melted and stirred to obtain a molten material, and the blank ...

Embodiment 3

[0040] Take oxidized polyethylene wax, isomerized fatty alcohol polyoxyethylene ether, nonylphenol polyoxyethylene ether, ethylene glycol, sodium hydroxide, deionized water, and combine oxidized polyethylene wax, isomerized fatty alcohol polyoxyethylene ether, Nonylphenol polyoxyethylene ether, ethylene glycol, sodium hydroxide and deionized water are mixed, emulsified, and cooled to room temperature to obtain a microemulsion; the polyether ether ketone resin is vacuum dried to obtain a pretreated resin , The microemulsion and the pretreatment resin are mixed and placed in a twin-screw extruder to melt, extrude and granulate to obtain composite particles. The composite particles are dried to obtain spinning raw materials, and the spinning raw materials are melt-spinned. To obtain composite fiber; the composite fiber and PTFE fiber are twisted to form a blank wire; the polyphenylene sulfide resin is melted and stirred to obtain a molten material, and the blank wire is immersed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com