Preparation method of boron carbide-based microstructure composite material

A technology of microstructure and composite materials, which is applied in the field of composite materials, can solve problems such as poor wetting effect of aluminum boron carbide and cracks in materials, and achieve the effect of avoiding sintering cracks and improving wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

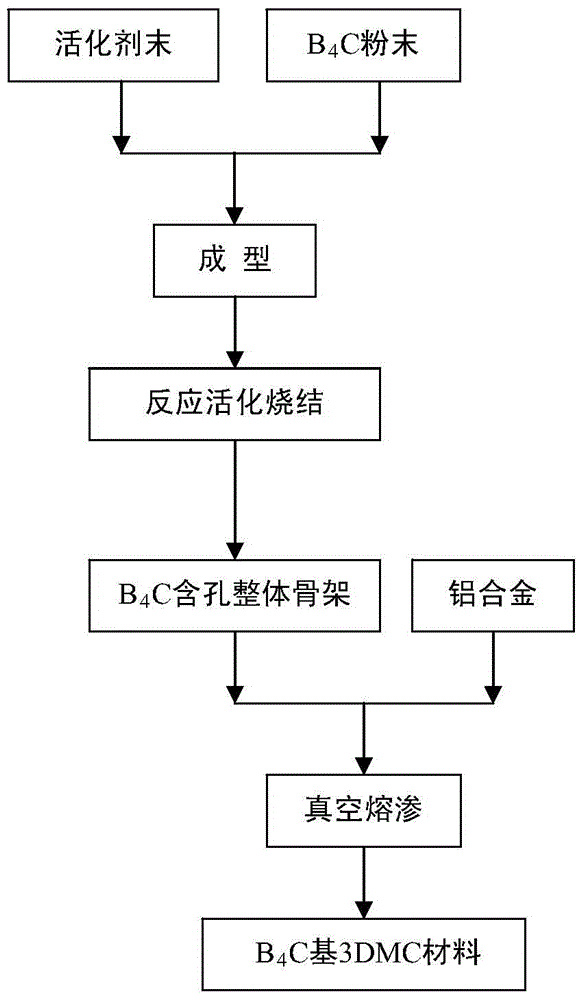

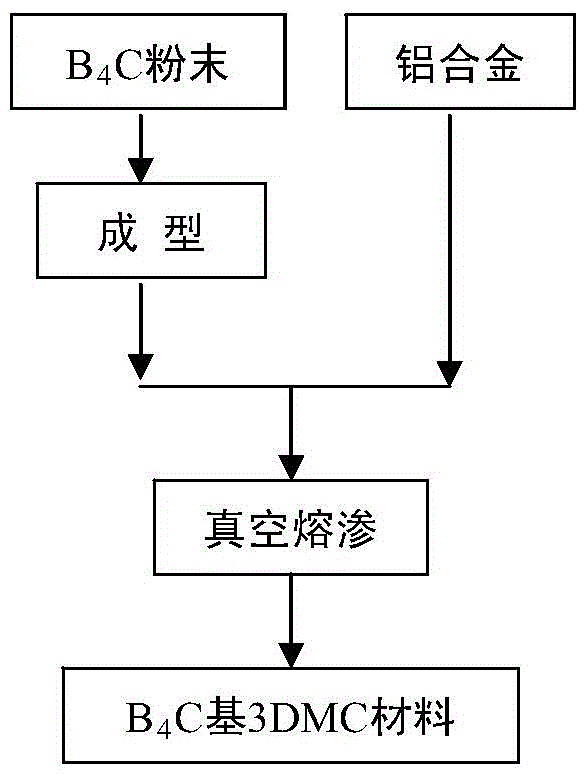

Method used

Image

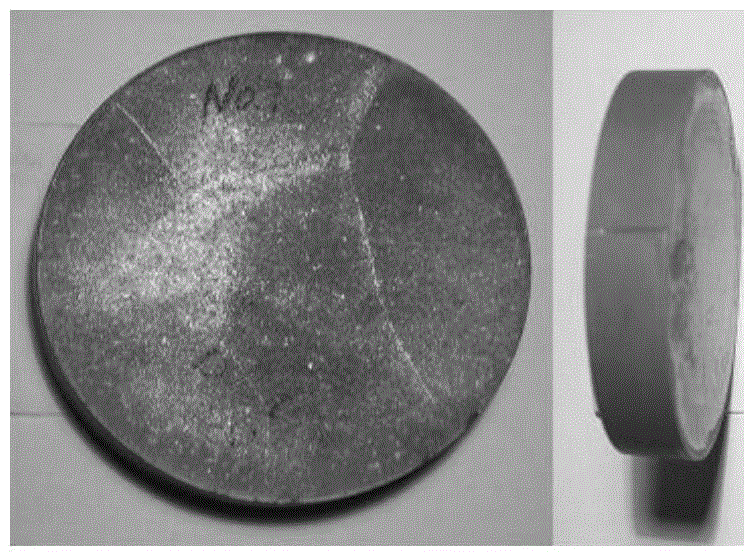

Examples

Embodiment 1

[0035] Embodiment 1 This embodiment is the preparation method of boron carbide-based microstructure composite material

[0036] Mix the boron carbide powder composed in Table 1 evenly, and the purity of boron carbide is higher than 98%; fill the boron carbide powder with a weight of 118g into the graphite mold cavity of D82mm×90mm, and then increase the density of the powder body by vibration to make carbonization The boron powder is evenly distributed.

[0037] Put a graphite plate (D75mm×5mm) with 4 small holes (D4mm~6mm) on the boron carbide powder body, and then put 100g of aluminum alloy (ZL102) to be infiltrated (the amount of aluminum alloy to be infiltrated is the target sample aluminum 1.3 times the theoretical ratio of the alloy) on the graphite plate, put them together into a vacuum furnace, and start sintering.

[0038] Table 1 Boron carbide particle size composition

[0039] Particle size range, micron

63~53

45~30

20~10

less than 10

...

Embodiment 2

[0043] Embodiment 2 This embodiment is the preparation method of boron carbide-based microstructure composite material

[0044] Mix the boron carbide powder composed of Table 2 evenly, and the purity of boron carbide is higher than 98%; fill the boron carbide powder with a weight of 118g into the graphite mold cavity of D82mm×90mm, and then increase the density of the powder body by vibration to make the boron carbide The powder is evenly distributed, and then a graphite plate (D75mm×5mm) with 4 small holes (D4mm~6mm) is placed on the boron carbide powder body, and then 100g of the aluminum alloy (ZL104) to be infiltrated (the aluminum alloy to be infiltrated The dosage is 1.4 times of the theoretical ratio of the target sample aluminum alloy) on the graphite plate, and they are put into a vacuum furnace together to start sintering.

[0045] Table 2. Boron carbide particle size composition

[0046] Particle size range, micron

63~53

45~30

20~10

less th...

Embodiment 3

[0050] The boron carbide powder mixes evenly (the particle size of boron carbide powder is composed with embodiment 1), and the purity of boron carbide is higher than 98%; The boron carbide powder that weight is 118g is filled in the graphite mold cavity of D82mm * 90mm, raises powder by vibration then The density of the body makes the boron carbide particles evenly distributed. Then put a graphite plate (D75mm×5mm) with 4 small holes (D4mm~6mm) on the boron carbide powder body, and then put 100g of aluminum alloy (ZL109) to be infiltrated (the amount of aluminum alloy to be infiltrated is about the target 1.3 times the theoretical ratio of the sample aluminum alloy) is placed on the graphite plate, and they are put into a vacuum furnace together to start sintering.

[0051] Before the sintering temperature rise starts, 100g of magnesium metal is placed in the heating zone of the vacuum furnace. The heating rate is 15°C / min~20°C / min, the temperature is raised to 1100°C~1150°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com