Cleaning solution for indissolvable water scale in mining automobile engine cooling system

A technology of automobile engine and cooling system, which is applied in the field of insoluble scale cleaning fluid for the cooling system of mining automobile engine, can solve the problems of metal corrosion in the cooling system, oil pollution in the cooling system, damage to the cylinder head gasket, etc., so as to reduce fuel consumption and improve power. effect of short cleaning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The following examples are only used to illustrate the present invention, and do not constitute a limitation to the scope of the claims. Other alternatives conceivable by those skilled in the art based on the contents of the description shall be within the protection scope of the claims of the present invention.

[0046] The cleaning conditions of Embodiments 1 to 4 of the insoluble scale cleaning liquid for the engine cooling system of mining vehicles of the present invention are to run the engine for 10 minutes at a speed of 1200 to 1400 r / min, and the engine running water temperature does not exceed 40°C.

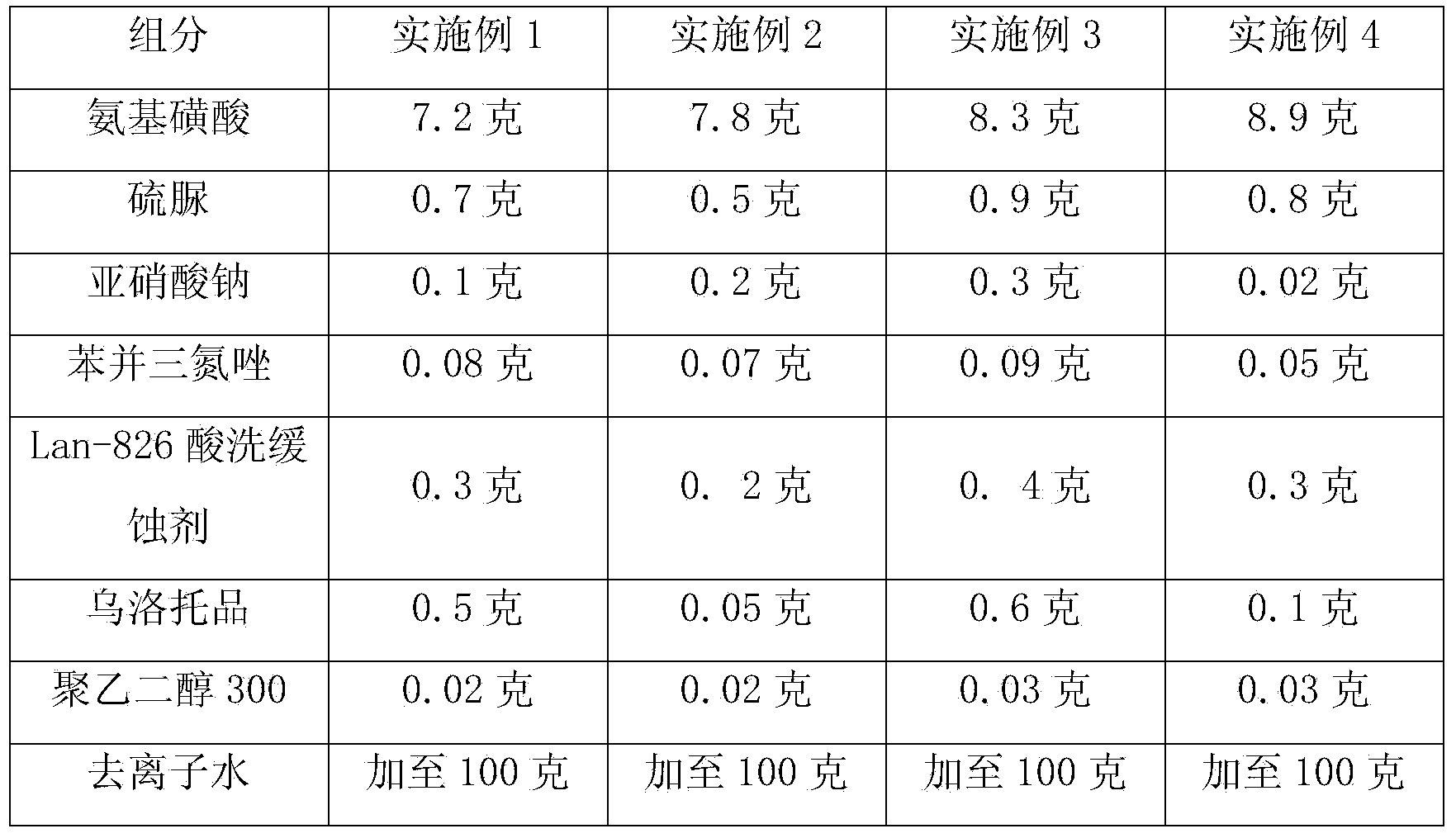

[0047] Embodiment 1~4 components and proportioning

[0048]

[0049] Preparation methods and steps of Examples 1-4 of the insoluble scale cleaning solution for the engine cooling system of mining vehicles of the present invention:

[0050] Step 1: Take sulfamic acid and sodium nitrite and add them to the metering and stirring tank according to the above ratio, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com