Seabed ore sand pulling sucker

A technology for ore sand and ore pulp, which is applied in the field of seabed ore sand scraping suction heads, can solve the problems of inability to realize raw ore sorting, non-wearability of submersible electric pumps, low productivity, etc. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

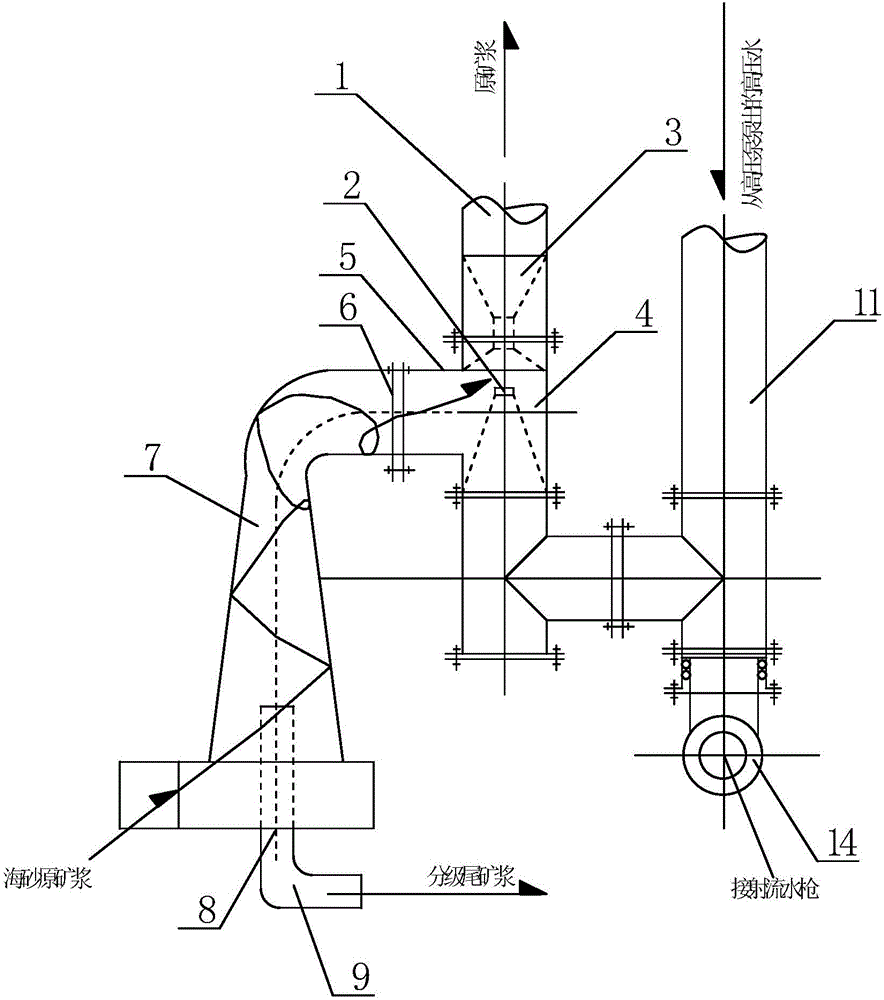

[0022] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0023] See figure 1 , is a structural schematic diagram of the present invention. The seabed ore scraping head of the present invention includes a volute classification cyclone 7, a high-pressure pump and a jet water gun 12. The volute classification cyclone 7 adopts an inverted form, and its bottom flow port 6 is located at The upper part is connected to the raw ore slurry delivery pipe 1 and the high-pressure water pipe 11 through the tee 5, and the high-pressure water pipe 11 drawn from the high-pressure pump is also connected to the jet water gun 12 through the rotating sleeve 10.

[0024] The connection between the high-pressure water pipe 11 and the raw ore pulp delivery pipe 1 is provided with a high-pressure water jet nozzle 2 and a mixing and diffusing pipe 3 .

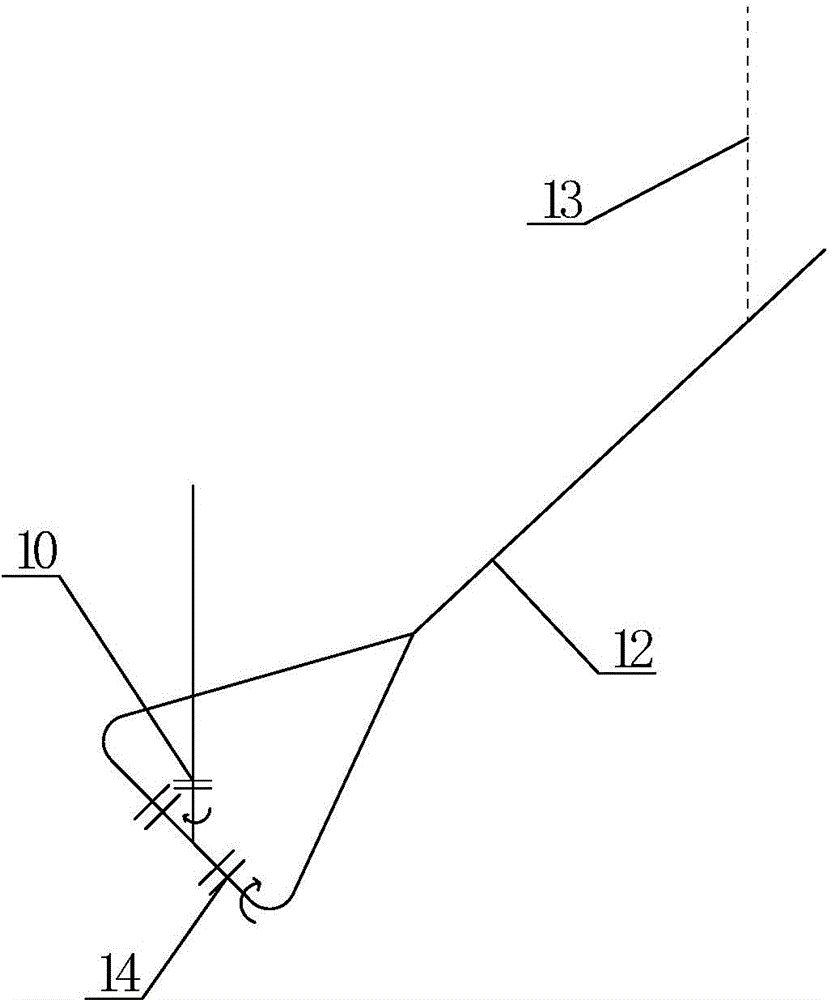

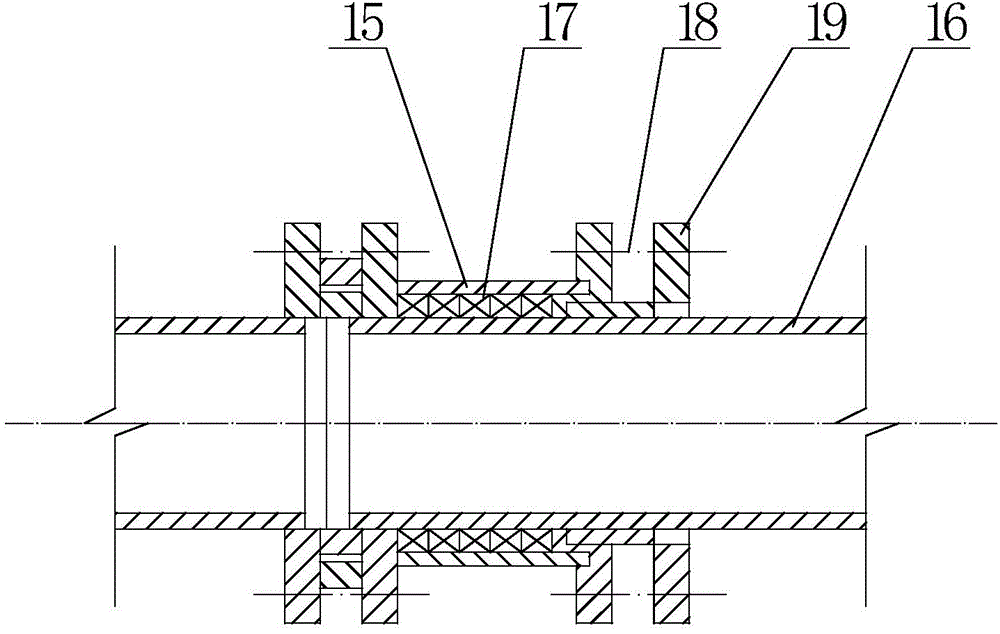

[0025] See image 3 , is a schematic diagram of the structure of the rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com