Train braking hardware-in-the-loop simulation testing stand and method

A semi-physical simulation and test bench technology, applied in general control systems, control/regulation systems, instruments, etc., can solve the problems of huge cost, can not fully consider the complexity of the brake machine and strong nonlinearity, and achieve the cost of the test. The effect of reducing, saving personnel, and accurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are used to illustrate the present invention, but should not be used to limit the scope of the present invention.

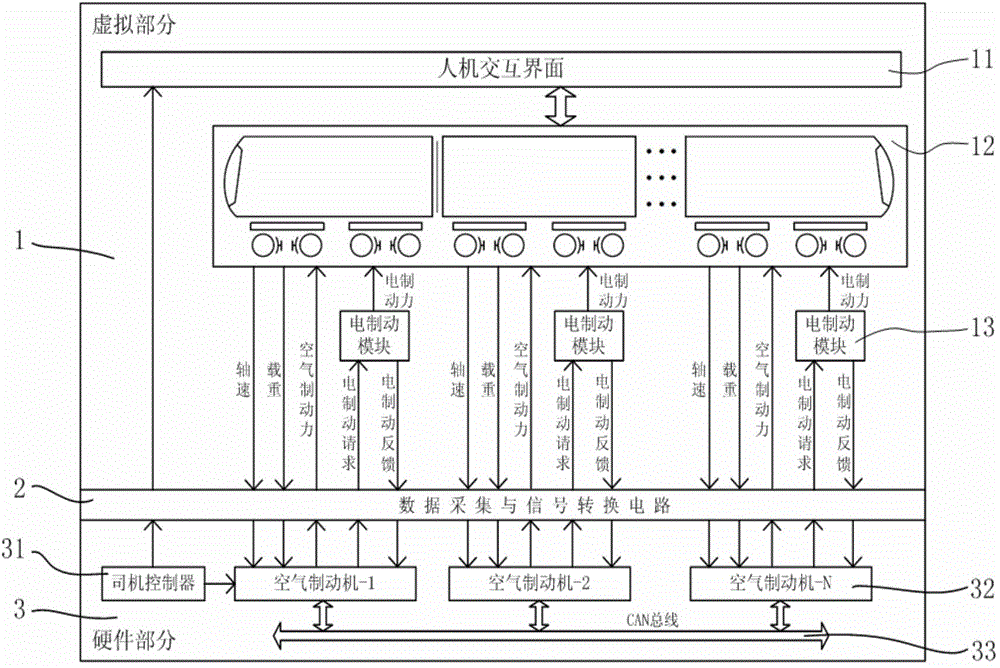

[0030] Such as figure 1 As shown, the train brake hardware-in-the-loop simulation test-bed of the present embodiment comprises: test-bed virtual part 1, test-bed hardware part 3 and data acquisition and signal conversion circuit 2; by air brake as test-bed hardware part 3, The test bench can fully consider the structural complexity and strong nonlinearity of the air brake, and provide the air removal system required for the train brake test through the virtual train, virtual train operating environment and virtual electric braking force of the virtual part 1 of the test bench. Test conditions other than motive hardware.

[0031] The virtual part 1 of the test bench is carried on the computer ter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com