Method for detecting abnormity of mechanical arm of detector

A robotic arm and inspection machine technology, applied in semiconductor/solid-state device testing/measurement, electrical components, circuits, etc., can solve the problem of inability to effectively monitor the abnormal changes of the robotic arm in real time, and achieve the effect of ensuring yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

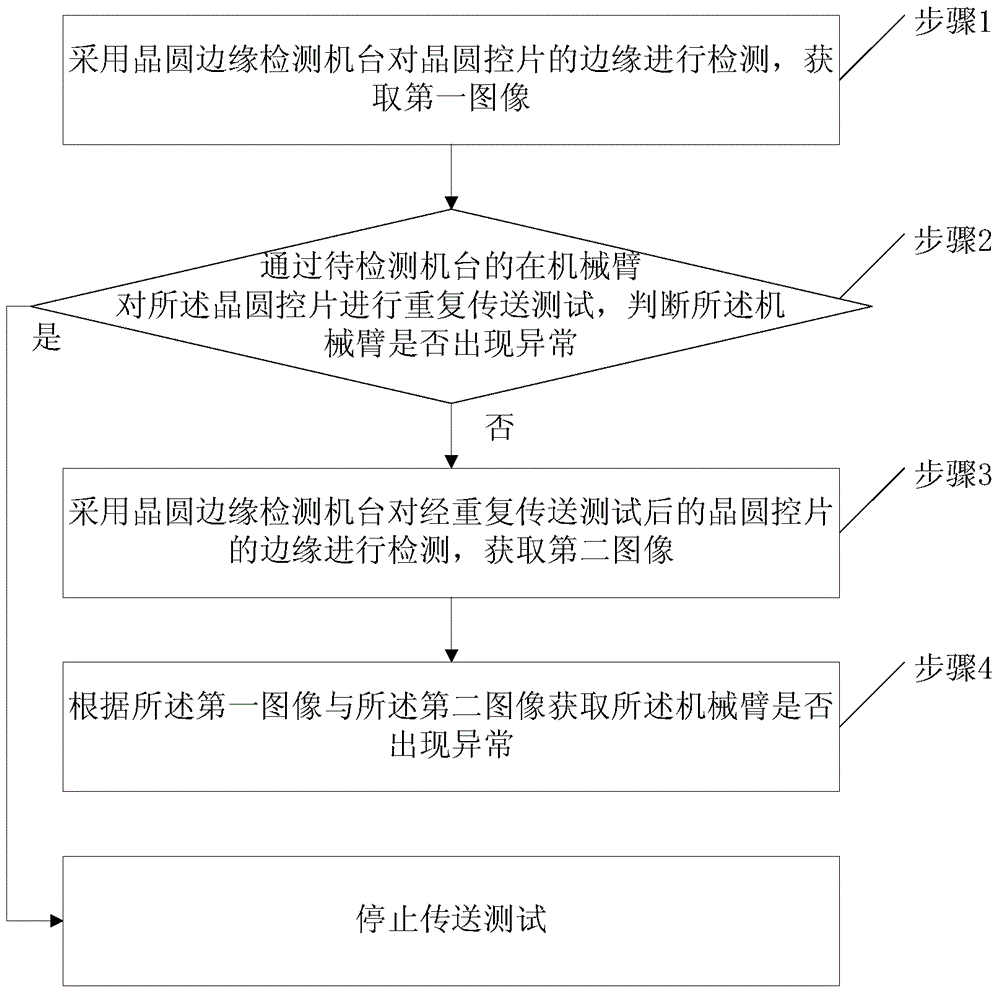

[0032] Such as Figures 1 to 8 As shown, the present invention provides a method for detecting an abnormality of a machine arm, comprising the following steps:

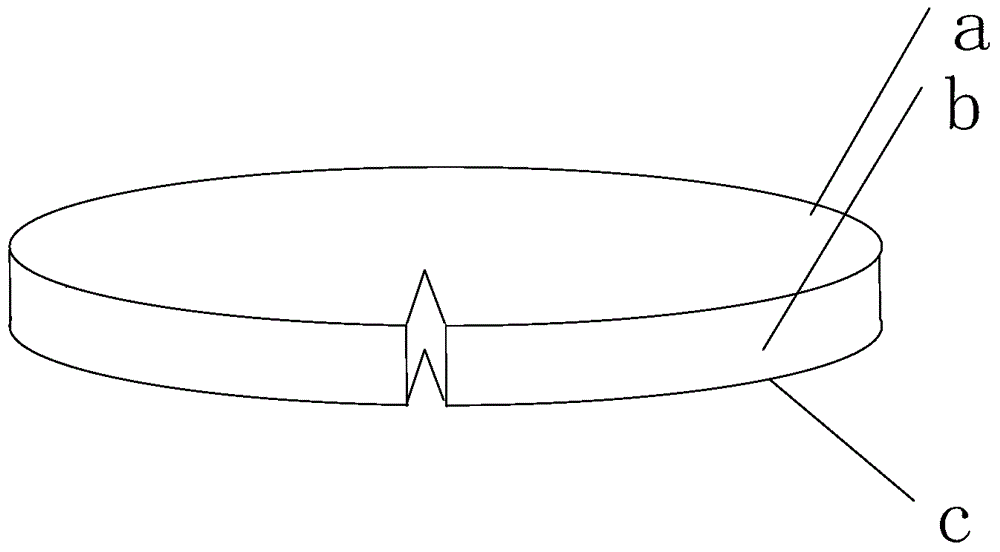

[0033] Step 1. Use a wafer edge detection machine to detect the edge of the wafer control sheet, and obtain the first image (such as image 3 , Figure 5 and Figure 7 As shown in the first image of upper surface edge a, side b and lower surface edge c), a low-resistance material layer is grown on the outer surface of the wafer control chip, and the thickness of the low-resistance material layer is a fixed value;

[0034] Step 2. Repeat the transfer test on the wafer control piece through the robot arm of the machine to be tested (that is, place the wafer control piece in the machine to be tested and perform a repeated delivery test ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com