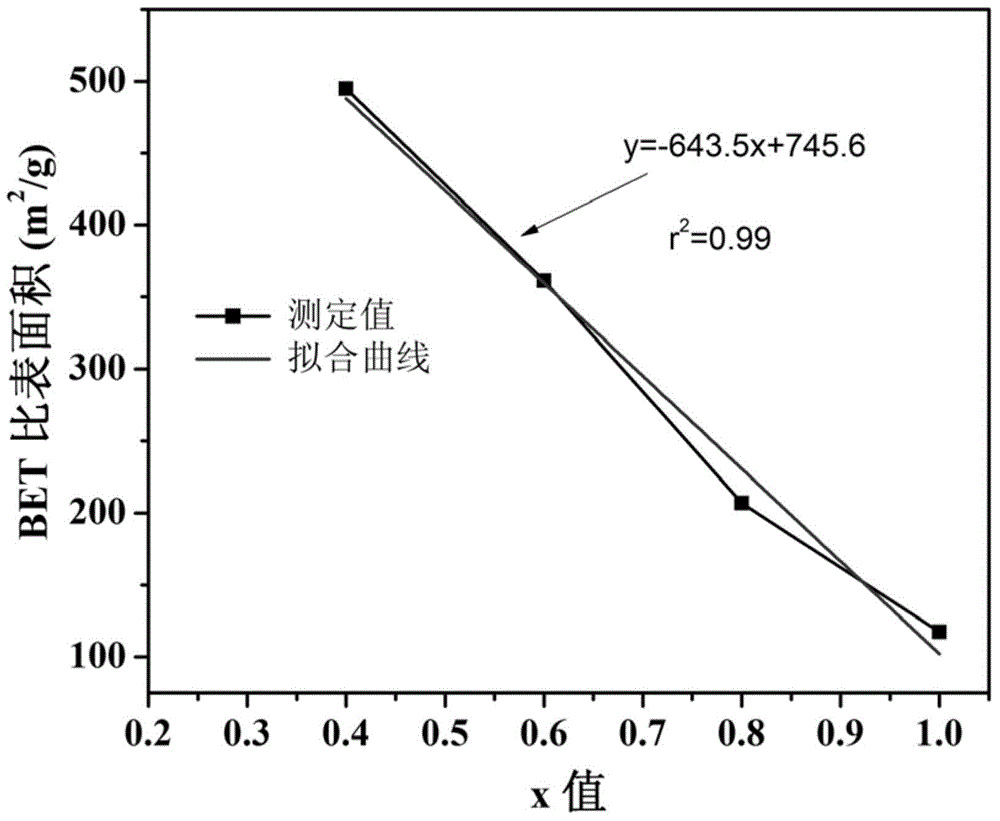

Synthetic method for TiSiCeOx catalytic materials with adjustable specific surface areas

A technology of catalytic materials and molar ratios, applied in chemical instruments and methods, separation methods, catalysts for physical/chemical processes, etc., to achieve the effects of good economy, easy control of preparation conditions, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

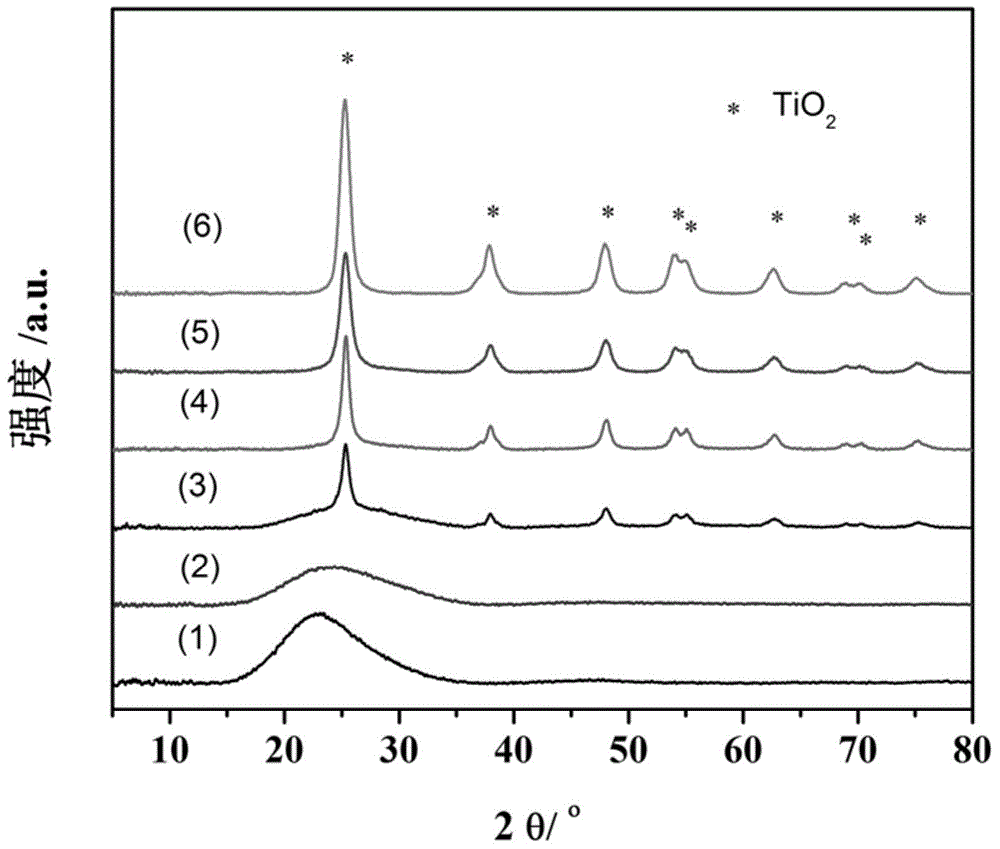

Embodiment 1

[0034] Weigh 10g PEG and dissolve in 200mL water, weigh Ce(NO 3 ) 3 ·6H 2 O2.17g was added to the above solution; TEOS44.65mL was weighed, dispersed in 50mL ethanol, added to the above solution, and continued to stir; 10% ammonia water was added dropwise to pH>9, stirred to obtain a white gel; aging 24h; filter, wash, dry at 120°C; roast at 450°C for 3h. Obtain 1# catalyst.

Embodiment 2

[0036] Weigh 10g PEG and dissolve in 200mL water, weigh Ce(NO 3 ) 3 ·6H 2 O2.17g was added to the above solution; weigh TEOS35.65mL, disperse it in 40mL ethanol, and add it to the above solution; measure TiCl 4 4.37mL, transferred to 10mL ethanol (ice-water bath), the resulting TiCl 4 Add the solution dropwise to the above mixture and continue to stir; add 10% ammonia water dropwise until pH>9, stir to obtain a white gel; age for 24 hours; filter, wash, and dry at 120°C; roast at 450°C for 3h. Get 2# sample.

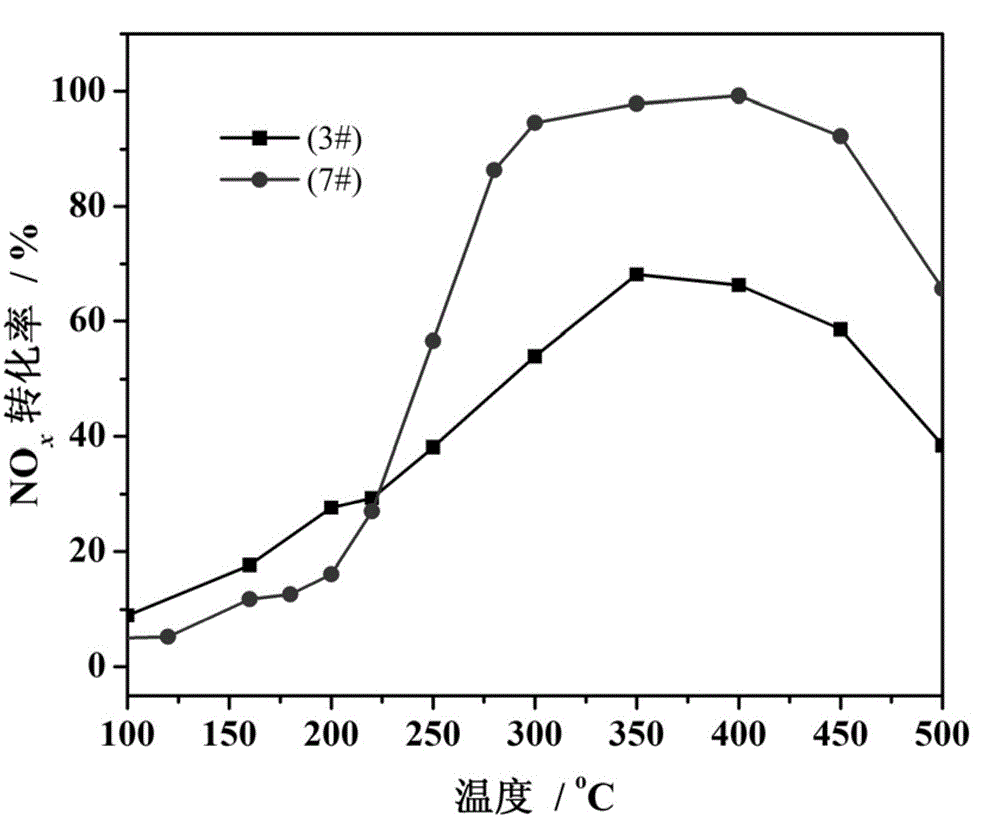

Embodiment 3

[0038] Weigh 10g PEG and dissolve in 200mL water, weigh Ce(NO 3 ) 3 ·6H 2 Add O2.17g to the above solution; weigh TEOS26.72mL, disperse it in 30mL ethanol, and add it to the above solution; measure TiCl 4 8.77mL, transferred to 20mL ethanol (ice-water bath), the obtained TiCl 4 Add the solution dropwise to the above mixture and continue to stir; add 10% ammonia water dropwise until pH>9, stir to obtain a white gel; age for 24 hours; filter, wash, and dry at 120°C; roast at 450°C for 3h. Obtain 3# sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com