Hot welding plate of thermofussion welding machine for underground coal mine

A hot-melt welding machine and hot-welding technology, which is applied in the field of hot-welding plates, can solve problems that affect mine operation safety, ignition, arc phenomenon, gas explosion, etc., and achieve electric sparks caused by static electricity, good conductivity, and structural design reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

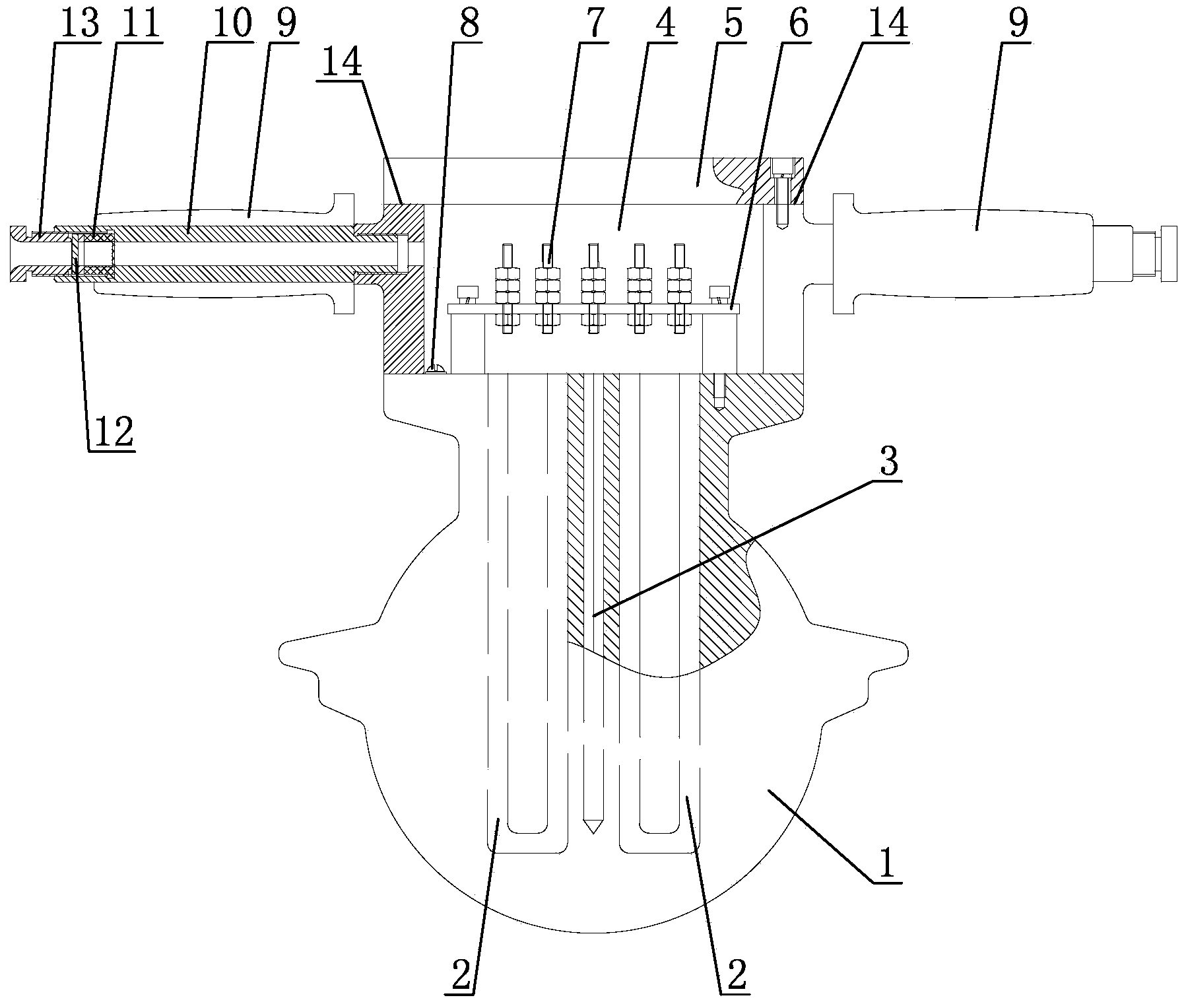

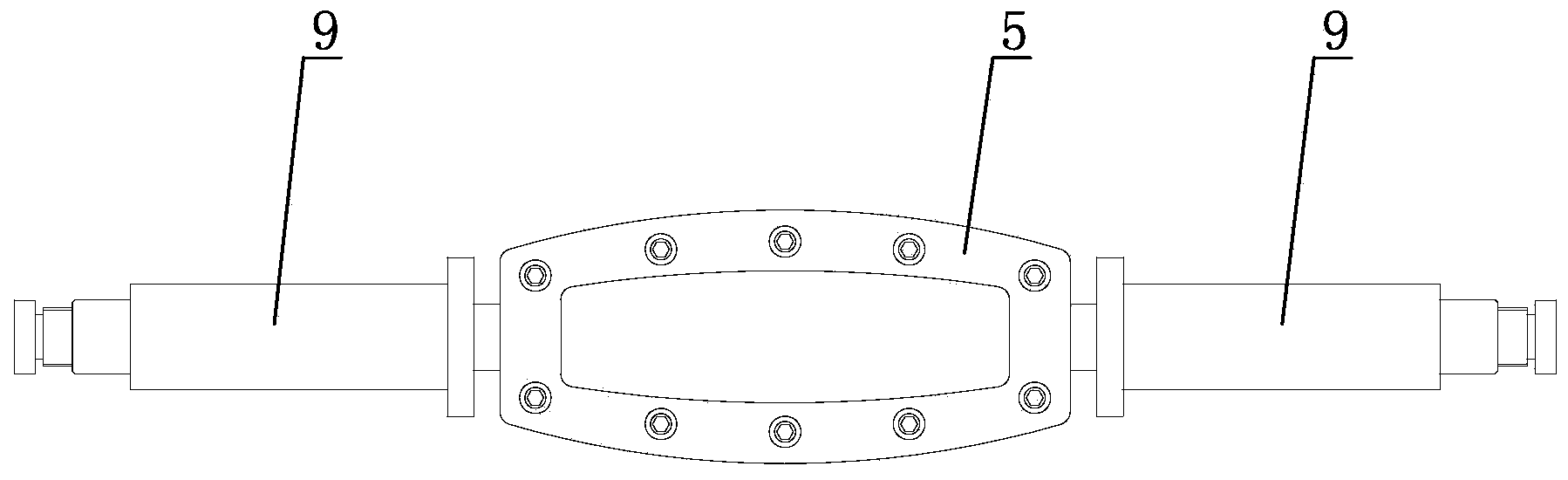

[0019] Such as Figure 1 ~ Figure 2 As shown, the present invention includes a hot plate body 1, in which several resistance heating wires 2 and a temperature sensor 3 are arranged, and the hot plate body 1 is made of explosion-proof aluminum. An explosion-proof wiring cavity 4 is arranged on the upper part of the hot plate body 1 , and an explosion-proof cover 5 for closing the explosion-proof wiring cavity 4 is arranged on the top of the explosion-proof wiring cavity 4 . The joint surface of the explosion-proof wiring chamber 4 and the explosion-proof cover body 5 is an explosion-proof surface 14 on which a conductive layer is arranged. Both the inner surfaces of the explosion-proof wiring chamber 4 and the explosion-proof cover 5 are provided with an arc-extinguishing paint layer. A bracket 6 is arranged in the explosion-proof wiring cavity 4, and several terminal posts 7 connected with the resistance heating wire 2 and the temperature sensor 3 are arranged on the bracket ...

Embodiment 2

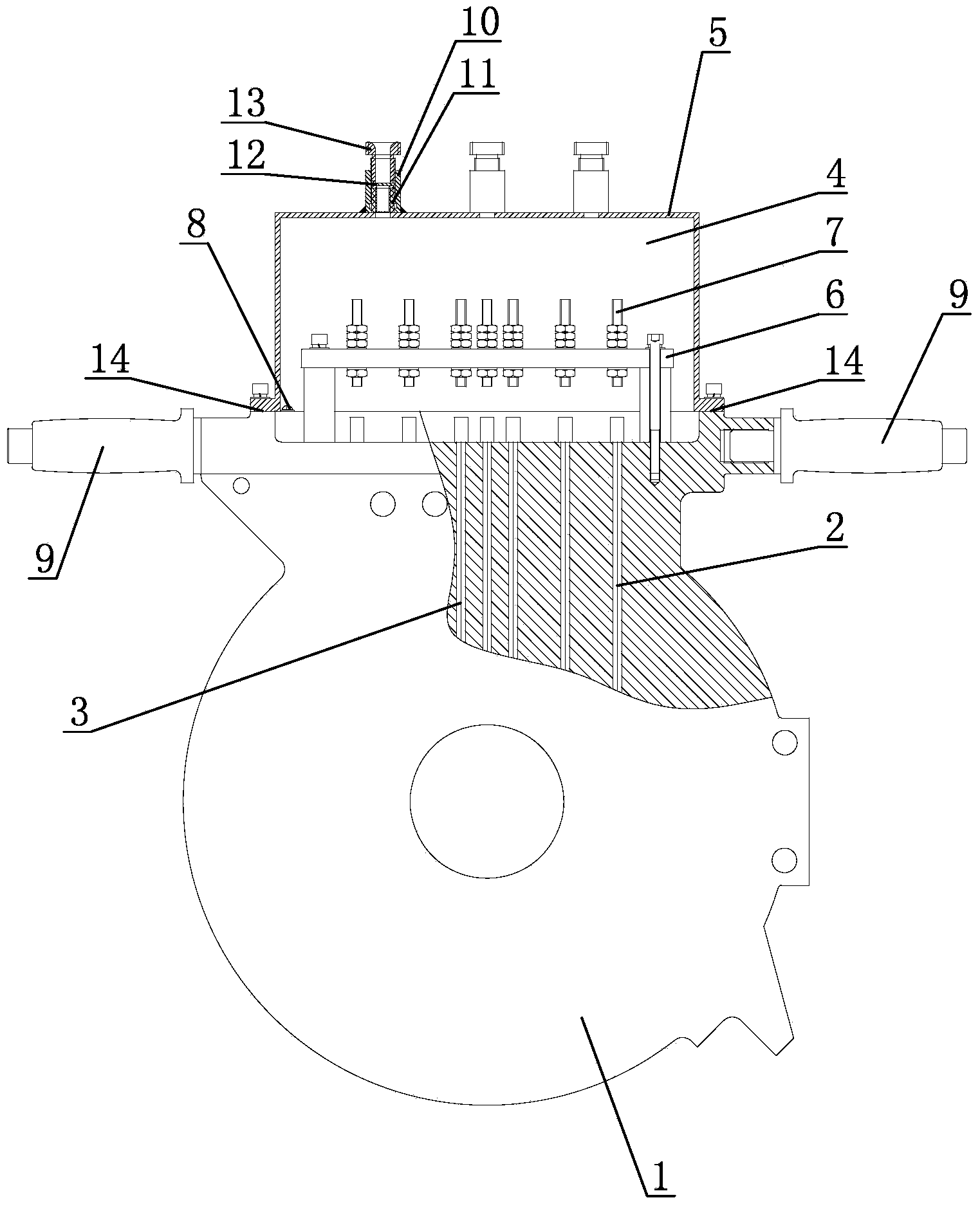

[0021] Such as Figure 3 ~ Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that three cable passages are uniformly arranged on the top of the anti-riot wiring cavity 4 . The cable channel includes a connecting sleeve 10 arranged on the top of the anti-riot wiring cavity 4. The connecting sleeve 10 communicates with the riot-proof wiring cavity 4. A sealing rubber ring 11 is provided in the connecting sleeve 10, and the connecting sleeve above the sealing rubber ring 11 10 is provided with a sealing plate 12, and the lower end of a trumpet-shaped interface sleeve 13 extends into the upper end of the connecting sleeve 10 and is threadedly connected with it. The other end face is in contact with the sealing rubber ring 11.

[0022] Before use, unscrew the horn-shaped interface sleeve 13 on one of the cable passages from the connection sleeve 10, take out the sealing plate 12, and stretch the cables of the plastic pipe welding device into the explosi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com