Airport de-icing equipment

A technology for anti-icing equipment and airports, applied to aircraft parts, ground equipment, spraying vehicles, etc., can solve the problems of high heating power, unstable temperature control, and long time, so as to increase the base temperature, save heating time, and stabilize good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

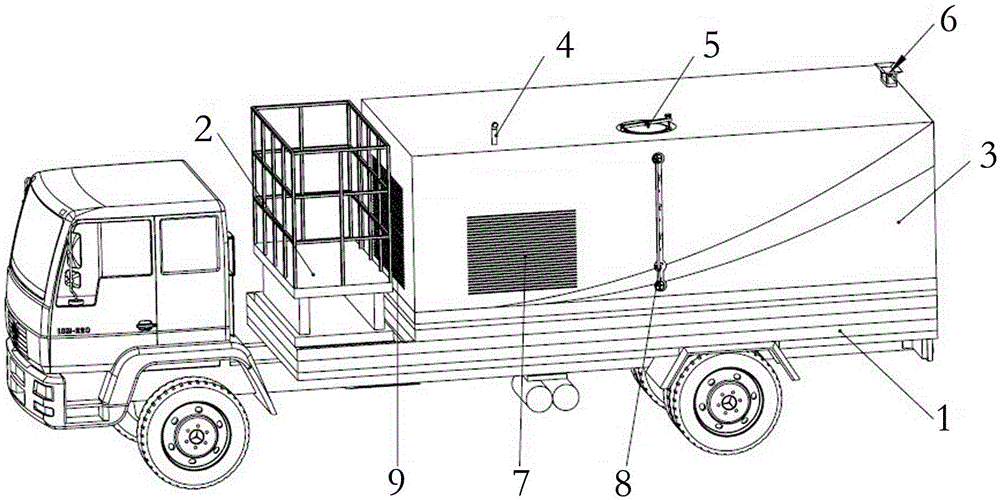

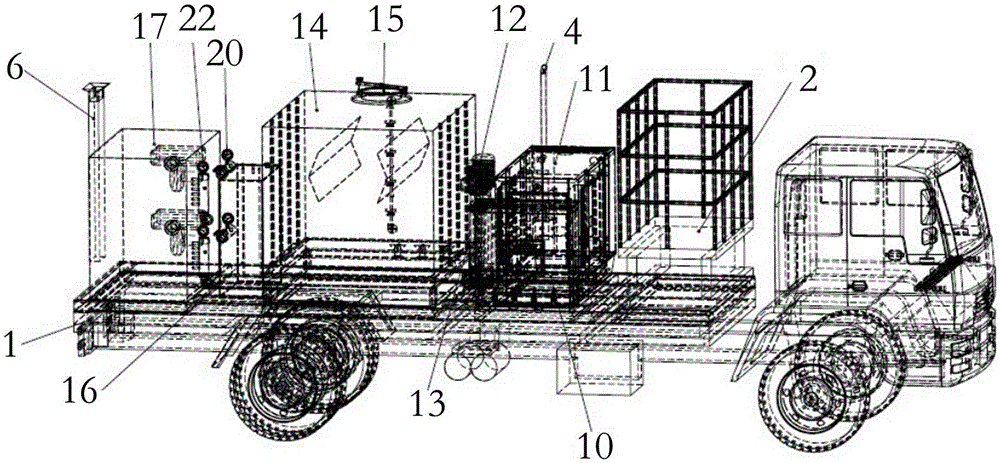

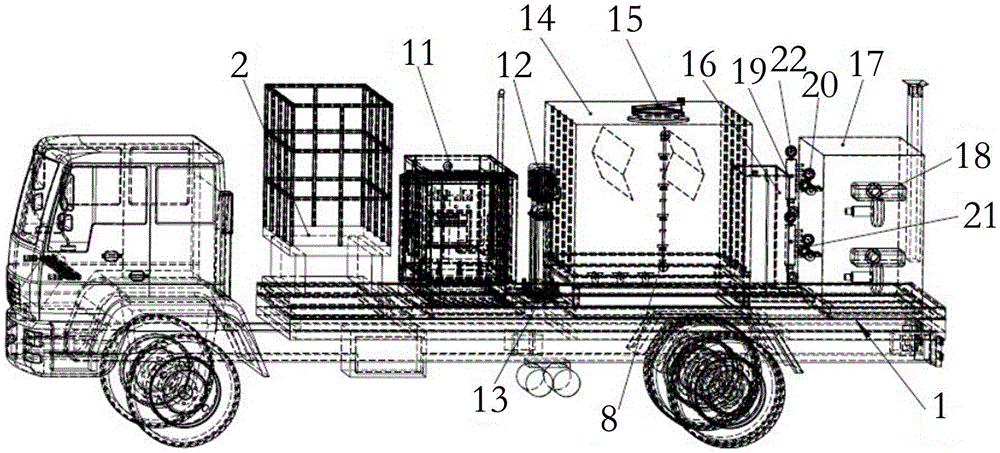

[0032] Refer to the attached Figures 1 to 5 , is an embodiment of a better-configured airport deicing and anti-icing equipment, which adopts a general-purpose automobile chassis 1, and of course, it can also be modified to adapt to the special application of the deicing and anti-icing equipment.

[0033] Such as Figure 1-5 Deicing and anti-icing equipment shown, the body of which consists of:

[0034] General Motors Chassis 1 (hereinafter referred to as the chassis), the wheeled chassis is shown in the figure, and the wheeled chassis has fast speed and low noise.

[0035] Compared with the GM chassis 1, some modification is carried out, and an automobile engine power take-off is added, or an engine is installed. The engine outputs two transmission shafts, one of which is connected to the original automobile transmission rod, and is passed through the transmission of the automobile. The system drives the car to run normally; the other shaft is connected to the input shaft o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com