Steel plate separating and moving device

A technology for separating and moving steel plates, which is applied in the direction of transportation and packaging, load hanging components, cranes, etc. It can solve the problems of affecting the surface quality of steel plates and easily scratching the surface of steel plates, so as to reduce the number of operators, reduce shaking, and ensure the surface quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

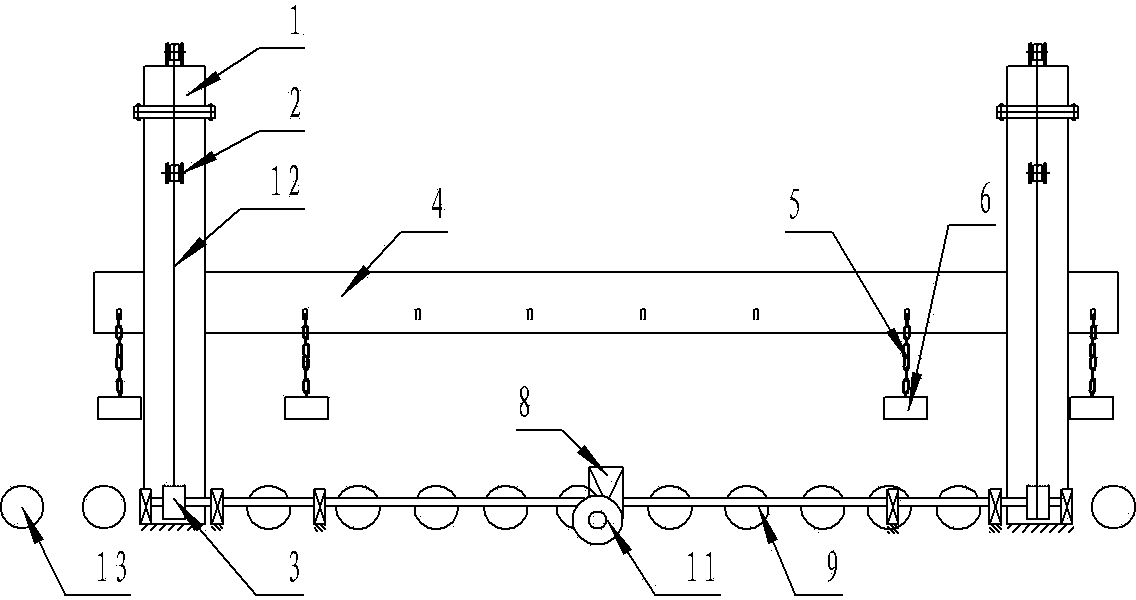

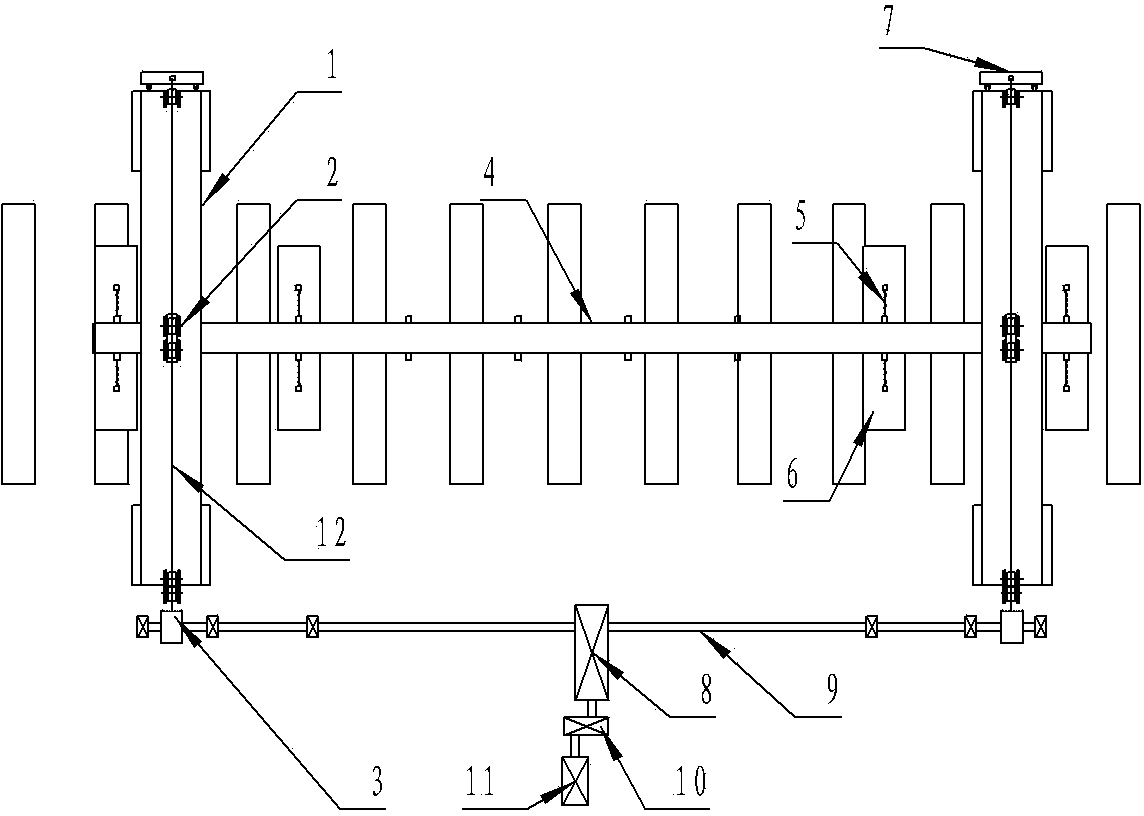

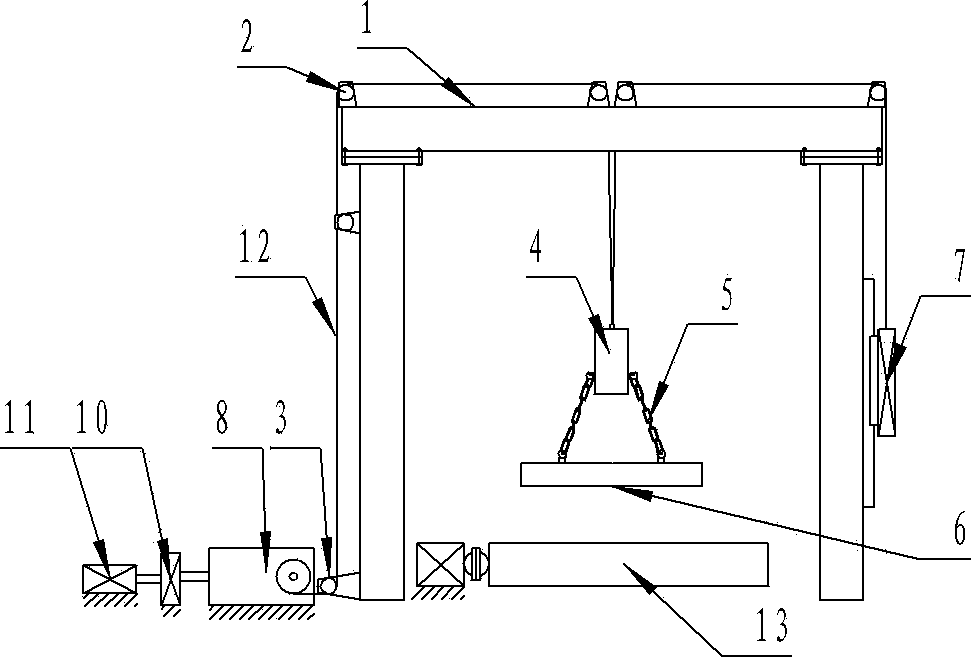

[0011] Such as Figure 1 to Figure 3 The shown steel plate shifting device includes a beam 1 straddling the roller table 13 . There are at least two beams 1 arranged front and back, and each beam 1 is supported by a column below. There are two beams 1 here, one hoisting beam 4 is hoisted under the two beams 1 through steel wire rope 12, each beam 1 is connected with hoisting beam 4 by two steel wire ropes 12, and a steel wire rope 12 is connected with guide pulley 2. Heavy block 7, another steel wire rope 12 connects winch 3 through guide pulley 2, and counterweight 7 is in order to balance the power on both sides of crossbeam 1, so that the hoist takes off and lands stably; The drive is connected through a gearbox 8, the gearbox 8 is connected to the rotating shaft 9 of the two hoist 3 reels, the gearbox 8 is connected to the speed reducer 10, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com