Doped vanadium dioxide powder and film and preparation method thereof

A technology of vanadium dioxide and powder, which is applied in the field of vanadium dioxide powder preparation, can solve the problems of little attention to the optical properties and color of thin films, not suitable for large-scale production, complicated control process, etc., to maintain visible light transmittance And solar control performance, good high and low temperature infrared control performance, low reaction temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Fluorine-doped vanadium dioxide powder doped with 20% molar percentage

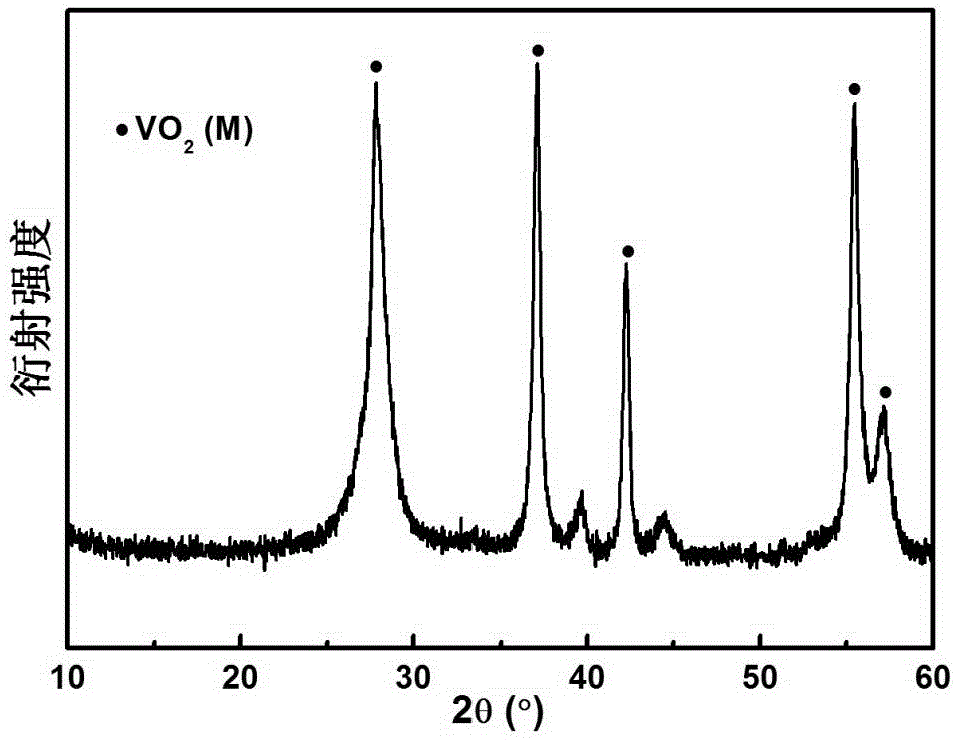

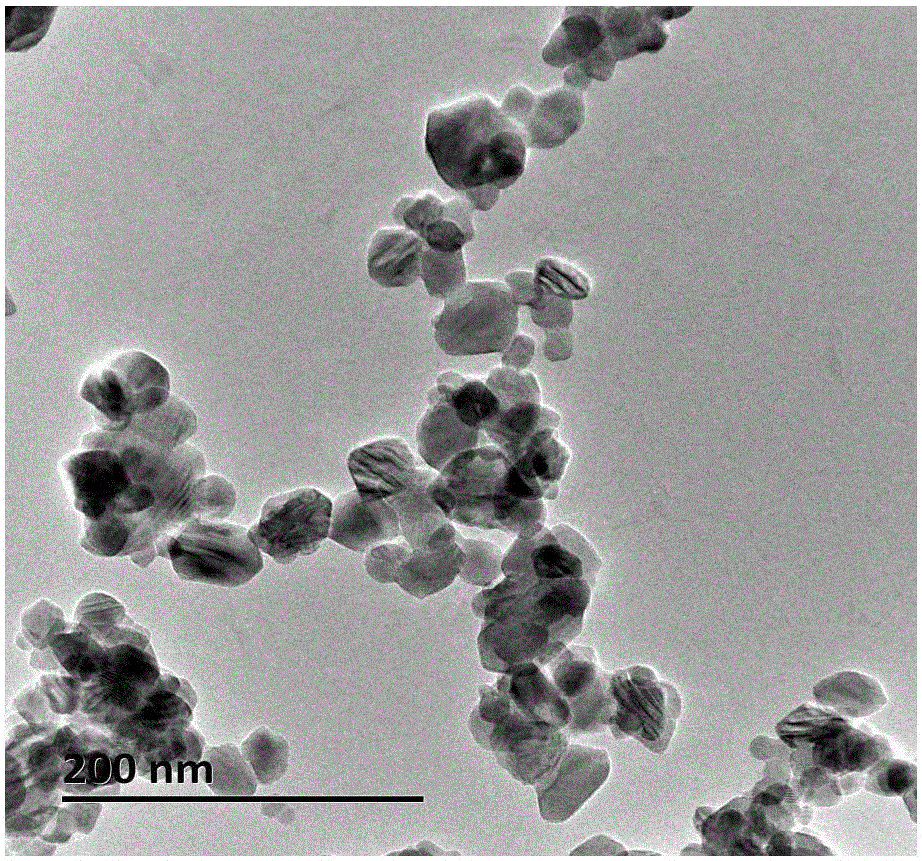

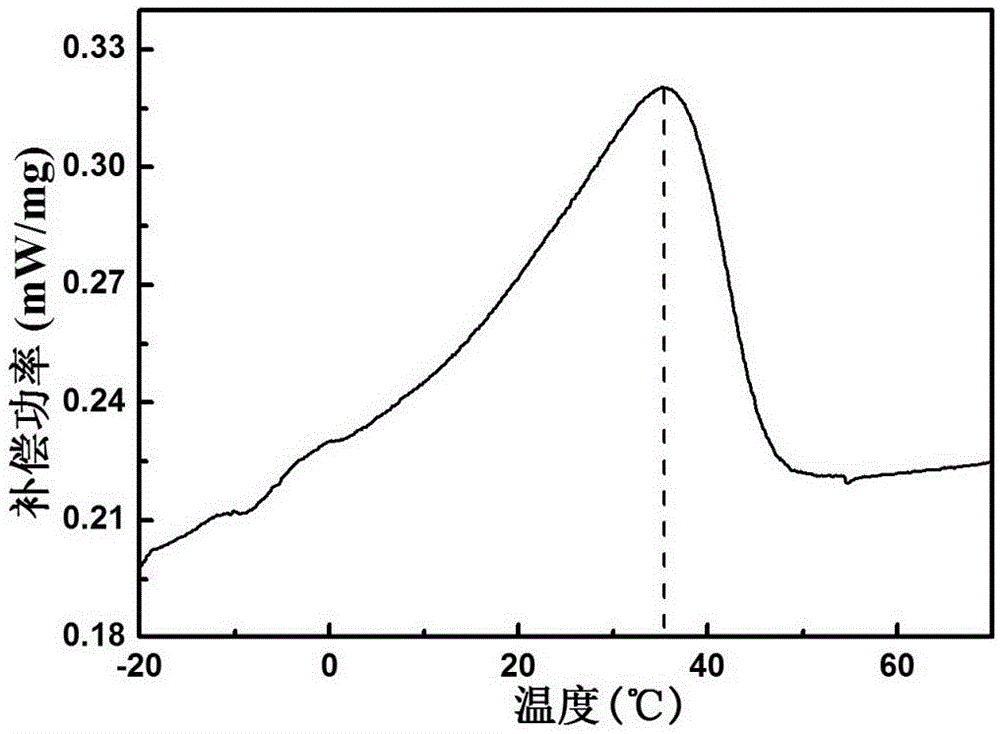

[0065] 10gVOSO 4 Powder and 3gNH 4 Dissolve F in 50ml of deionized water, titrate with 1mol / L NaOH solution, and keep stirring. After the titration is complete, put the suspension into a 50ml hydrothermal kettle filled with 45ml of deionized water, and conduct a hydrothermal reaction at 230°C for 96 Hours, centrifuged and dried to obtain fluorine-doped vanadium dioxide powder, the molar ratio of fluorine atoms was 20% through elemental analysis. Such as figure 1 The crystal phase shown in the XRD spectrum is pure M phase. From figure 2 In TEM, it can be found that the fluorine-doped vanadium dioxide is granular, with a size of about 30nm. Such as image 3 The DSC curve shows that the fluorine-doped vanadium dioxide powder has a phase transition property, and the phase transition temperature drops to 35°C, indicating that fluorine doping can effectively reduce the phase transition temperature...

Embodiment 2

[0067] Chlorine-doped vanadium dioxide powder doped with 10% molar percentage

[0068] 10gVOC 2 o 4 ·5H 2 Dissolve O powder and 2g KCl in 50ml deionized water, titrate with 1mol / L NaOH solution, and keep stirring. After the titration is complete, put the suspension into a 50ml hydrothermal kettle filled with 45ml deionized water, at 300°C The hydrothermal reaction was carried out for 12 hours, and the chlorine-doped vanadium dioxide powder was obtained by centrifuging and drying, and the molar ratio of chlorine atoms was 10% through elemental analysis. Figure 4 The phase of the chlorine-doped vanadium dioxide powder shown is M phase, the phase transition temperature of the powder is 45°C, the particle size is 40nm, and the carrier concentration is 3.2×10 when the powder is pressed into tablets at 25°C 18 cm -3 .

Embodiment 3

[0070] Bromine-doped vanadium dioxide powder doped with 12% molar percentage

[0071] 10gVOCl 2 Dissolve the powder and 3gNaBr in 50ml deionized water, titrate with 1mol / L NaOH solution, and keep stirring. After the titration is complete, put the suspension into a 50ml hydrothermal kettle filled with 45ml deionized water. Thermally reacted for 12 hours, centrifuged and dried to obtain bromine-doped vanadium dioxide powder, the molar ratio of bromine atoms was 12% through elemental analysis. The phase of bromine-doped vanadium dioxide powder is M phase, the phase transition temperature is 50°C, the particle size is 50nm, and the carrier concentration is 6.1×10 when the powder is pressed into tablets at 25°C 17 cm -3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com