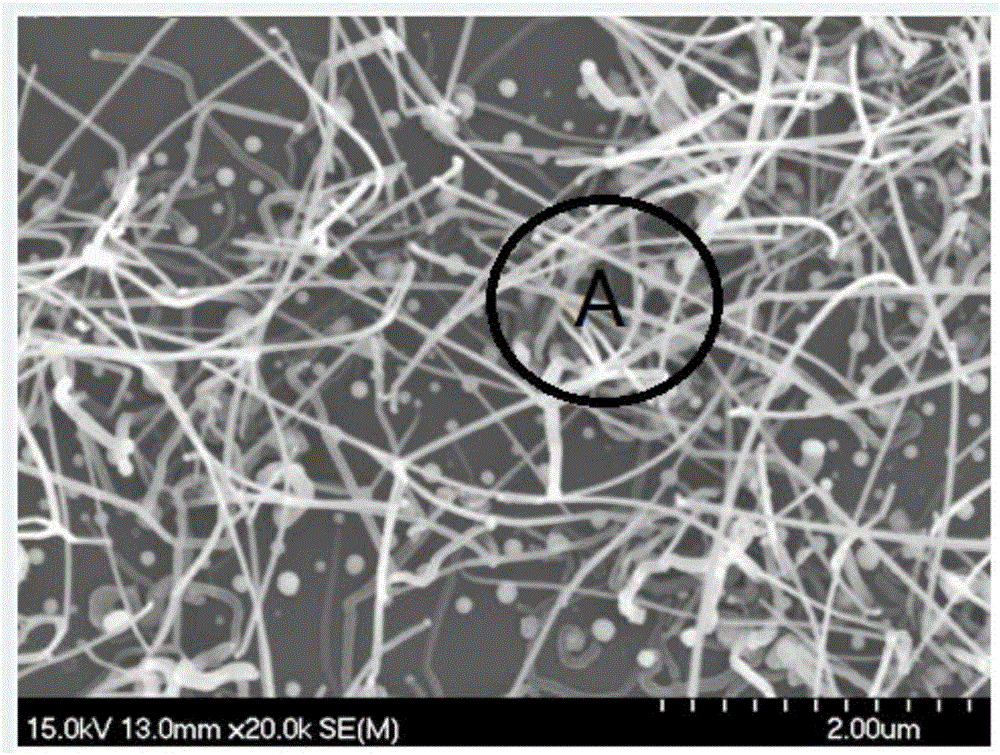

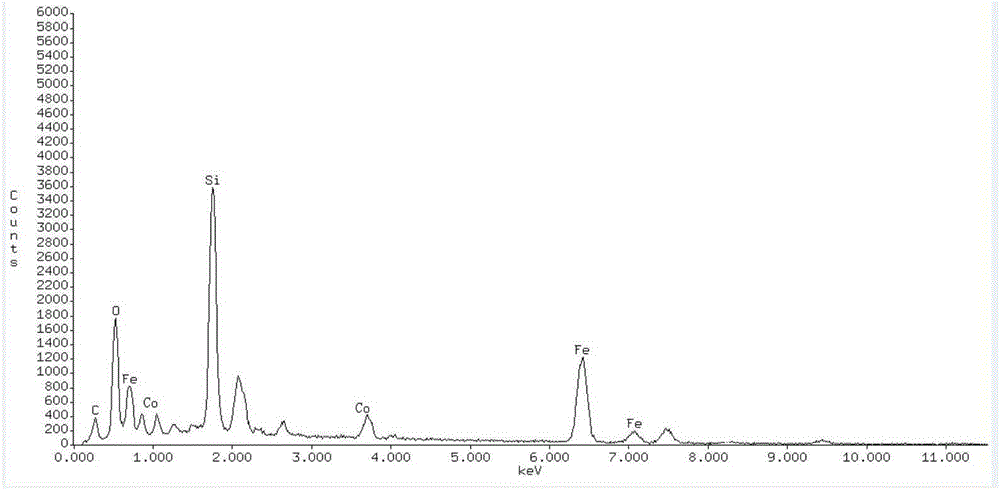

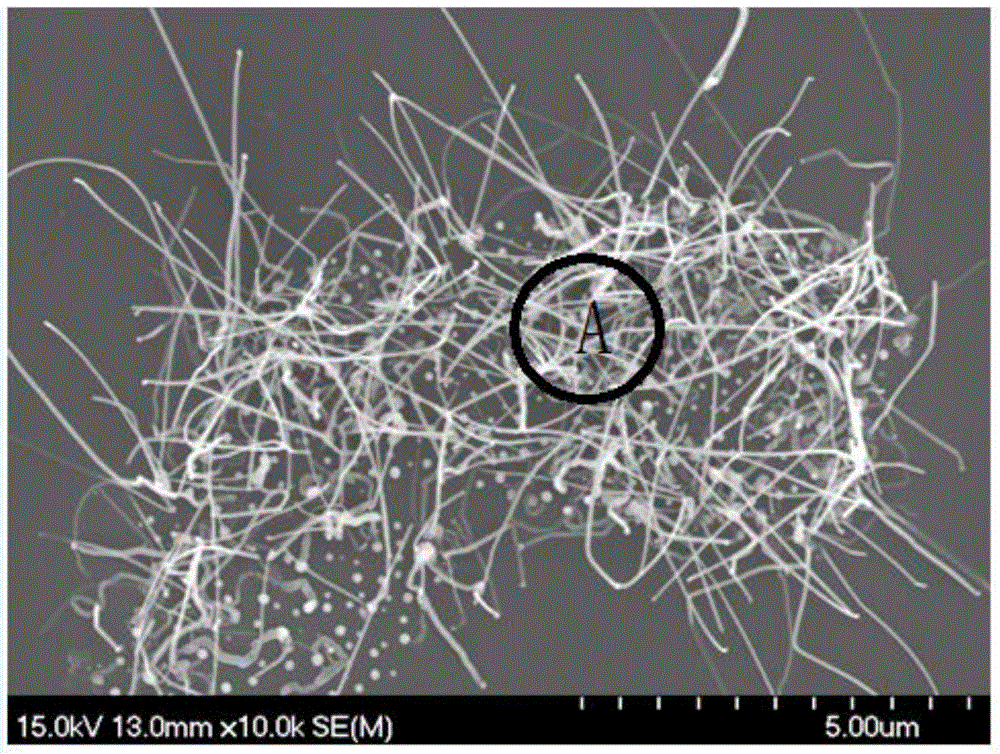

A preparation method of one-dimensional coxfe3-xo4 magnetic nanowires with composition gradient

A technology of coxfe3-xo4 and composition gradient, applied in the field of CoxFe3-xO4 one-dimensional magnetic nanowires and their preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) FeCl with a purity of 99.99% 3 、CoBr 2 The molar ratio is 2:1 (FeCl 3 2.59g, CoBr 2 1.75g), ground into powder respectively, put into alumina porcelain boats respectively, and put into two small corundum tubes with inner diameter of 5cm and length of 50cm respectively. 1. One end of a large corundum tube with a length of 1m, the direction of the small corundum tube is parallel to the large corundum tube, the other end of the large corundum tube is placed on the substrate, the two small corundum tubes are in a straight line with the substrate as a whole, and the porcelain boat inside the two small corundum tubes The positions are staggered so that FeCl 3 Powder located at CoBr 2 Between powder and matrix, and FeCl 3 Powder and CoBr 2 The distance between the powders in the direction perpendicular to the matrix is, 5cm, FeCl 3 , The distance between the substrates is 10cm.

[0031] (2) Place the large corundum tube in a tube furnace so that the FeCl in the lar...

Embodiment 2

[0034] (1) FeCl with a purity of 99.99% 3 and CoBr 2 The molar ratio is 2:1 (FeCl 3 2.59g, CoBr 2 1.75g), ground into powder respectively, put into alumina porcelain boats respectively, and put into two small corundum tubes with inner diameter of 5cm and length of 50cm respectively. 1. One end of a large corundum tube with a length of 1m, the direction of the small corundum tube is parallel to the large corundum tube, the other end of the large corundum tube is placed on the substrate, the two small corundum tubes are in a straight line with the substrate as a whole, and the porcelain boat inside the two small corundum tubes The positions are staggered so that FeCl 3 Powder located at CoBr 2 Between powder and matrix, and FeCl 3 Powder and CoBr 2 The distance between the powders in the direction perpendicular to the matrix is 8 cm, FeCl 3 , The distance between the substrates is 10cm.

[0035] (2) Place the large corundum tube in a tube furnace so that the FeCl in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com