Special materials for ultra-high molecular weight polyethylene pipes and their preparation and application

An ultra-high molecular weight, polyethylene pipe technology, applied in the field of polymer processing and molding, can solve the problems of not meeting the industrialized production of industrial pipes, too late for cooling and solidification, and low pipe forming efficiency, achieving dimensional stability and fast cooling crystallization rate. , the effect of improving the preparation process and method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

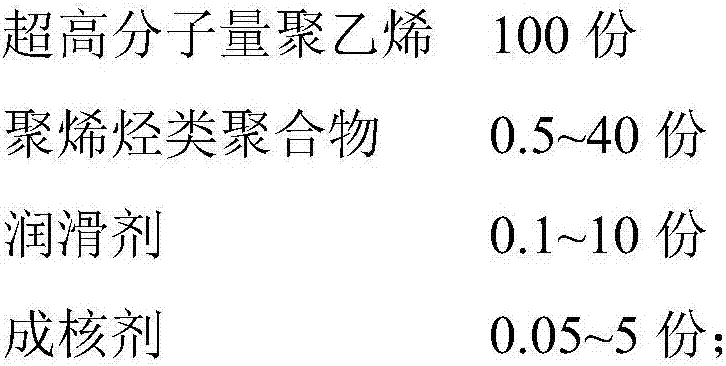

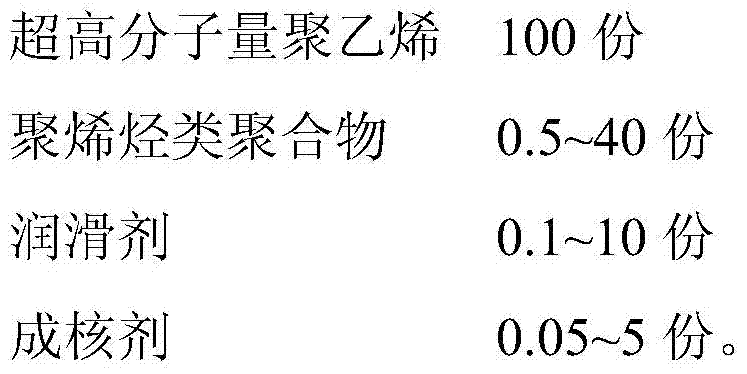

Method used

Image

Examples

Embodiment 1

[0034] Put 100 parts by weight of ultra-high molecular weight polyethylene with a viscosity average molecular weight of 2.5 million, 40 parts of metallocene low-density polyethylene, 5 parts of chlorinated paraffin, and 1 part of p-hydroxybenzoic acid in a mixer and mix them for 60 minutes. , and then put the mixture into a single-screw extruder for extrusion, the extrusion speed is 2.5 m / h, the outer diameter of the pipe is 1200 mm, the wall thickness of the pipe is 40 mm, and the extrusion melt temperature of the pipe is 280 ° C.

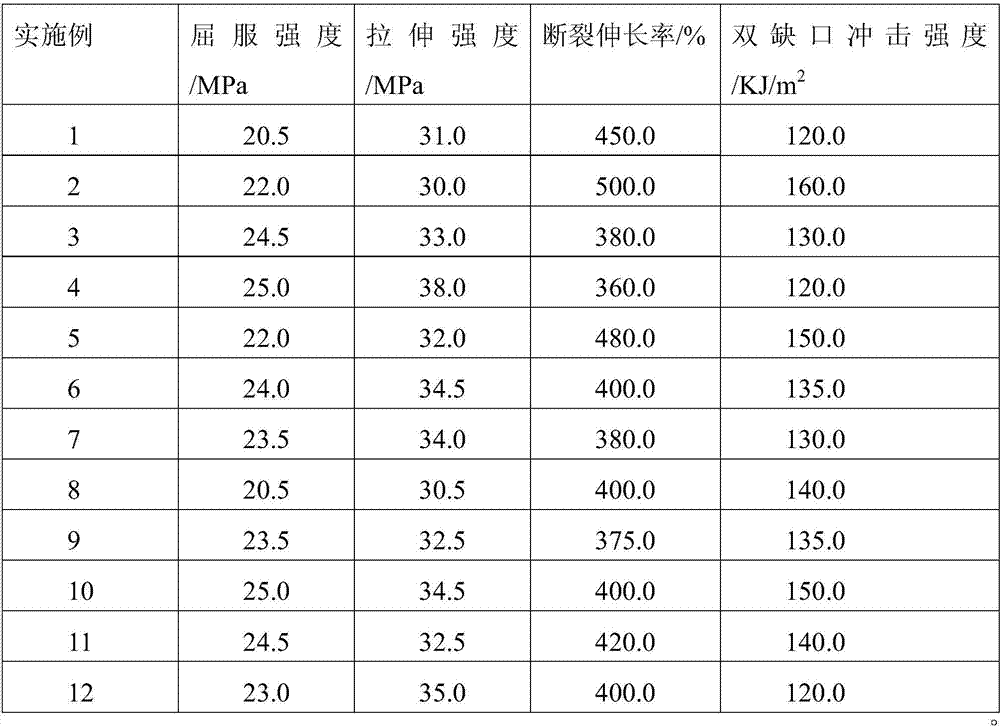

[0035] The performance indicators of the pipes are shown in Table 1.

Embodiment 2

[0037] Put 100 parts by weight of ultra-high molecular weight polyethylene with a viscosity average molecular weight of 1.5 million, 0.5 parts of metallocene ultra-low density polyethylene, 2 parts of polyethylene wax, 2 parts of paraffin wax, and 0.1 part of calcium carbonate in a mixer for mixing. For 1 minute, then the mixture is put into a single-screw extruder to extrude, the extrusion speed is 3.0 m / hour, the outer diameter of the pipe is 630 mm, the wall thickness of the pipe is 10 mm, and the extrusion melt temperature of the pipe is 220°C.

[0038] The performance indicators of the pipes are shown in Table 1.

Embodiment 3

[0040] By weight, 100 parts of ultra-high molecular weight polyethylene with a viscosity average molecular weight of 3.5 million, 5 parts of metallocene low-density polyethylene, 5 parts of metallocene high-density polyethylene, 2 parts of polyethylene wax, 0.1 part of paraffin, 0.5 part of stearic acid Calcium and 1 part of talcum powder are placed in a mixer and mixed for 10 minutes, then the mixture is put into a single-screw extruder and extruded at a speed of 3.5 m / h, and the outer diameter of the pipe is 250 mm. The wall thickness of the pipe is 10 mm, and the extrusion melt temperature of the pipe is 250 °C.

[0041] The performance indicators of the pipes are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com