Water-tank water temperature stratification structure used for CO2 heat-pump water heater

A technology of heat pump water heater and layered structure, which is applied in the direction of fluid heater, lighting and heating equipment, etc., can solve the problems of rising water temperature of supply gas cooler, lowering of COP of heat pump water heater system, and inability to provide sufficient hot water, etc., to achieve Reduce temperature difference heat transfer and improve COP effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

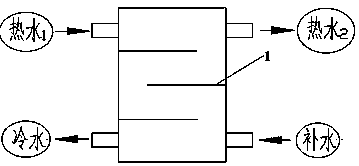

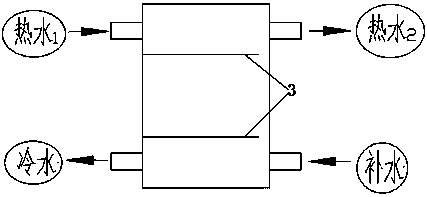

[0023] Such as Figure 1 to Figure 7 As shown, a water temperature layered structure used in the water tank of a CO2 heat pump water heater, a horizontal baffle 1 is added in the water tank (such as figure 1 As shown), the fluid in the water tank is layered to reduce the mixing of hot and cold fluids for heat exchange. Although the fluids in each layer are not closed and can flow and exchange heat with each other, they can stratify the temperature in the water tank, thereby providing users with a sufficiently high temperature. Hot water, while the circulating water flowing to the air cooler is kept at a lower temperature, increasing the CO 2 COP for heat pump water heater systems.

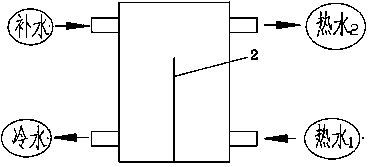

[0024] Add a vertical baffle 2 in the water tank (such as figure 2 As shown), the "low temperature side" and "high temperature side" in the water tank are separated, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com