Method and equipment for testing detergency of marine medium-speed engine lubricating oil

A technology of engine lubricating oil and test method, applied in the direction of using material absorption and weighing, etc., can solve the problems of simulating the working environment of marine internal combustion engines, etc., and achieve the effects of short test period, accurate evaluation results and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

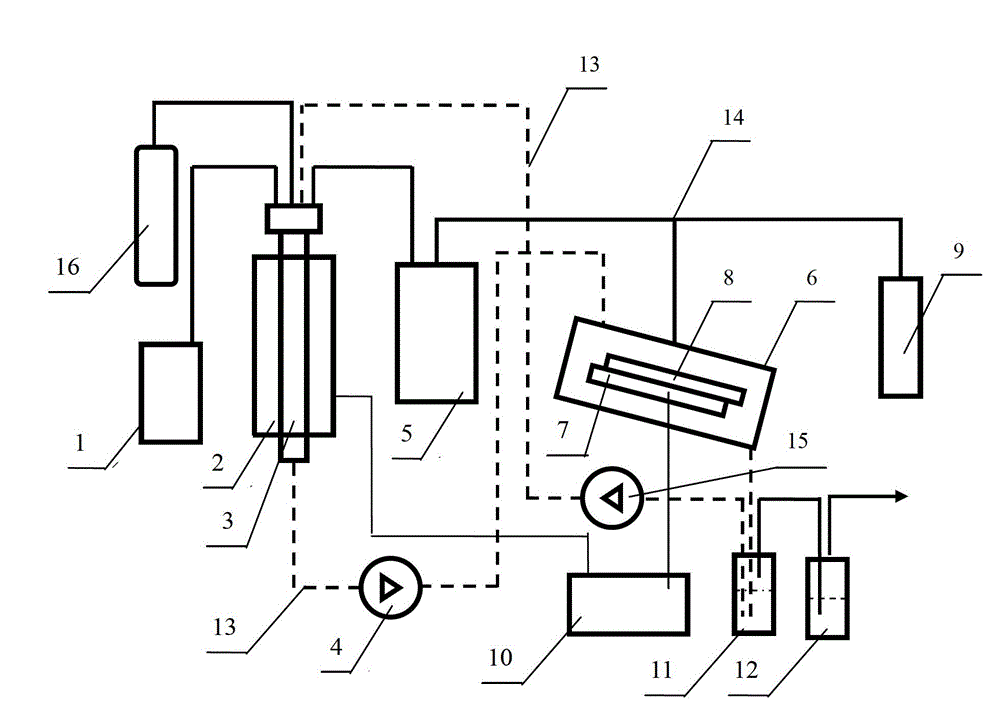

[0019] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0020] As shown in the figure, the test equipment for the detergency of lubricating oil for marine medium-speed engines is composed of an oil oxidation container 3, an air supply system, a sealing tester 6, a temperature controller 10, and an oil supply system. The gas supply system includes an oxygen bottle 16, a diesel burner 1 and a sulfur dioxide gas bottle 9. The oil supply system includes an oil storage bottle 11 , a return metering pump 15 and an input metering pump 4 . The oil product oxidation container 3 is made of stainless steel tubes sealed at both ends, and a heater 2 is arranged outside the stainless steel tube, and the heating temperature is controlled by a temperature controller 10 . The top of the stainless steel pipe communicates with the oxygen cylinder 16, the diesel burner 1, the soot filter 5 and the oil storage bottle 11 through the gas pipeli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com