Laboratory microwave deicing instrument

A laboratory, microwave technology, applied in the direction of material analysis, instruments, and scientific instruments using microwave means, can solve the problem of no microwave deicing experimental instruments, etc., and achieve the effect of simple structure and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

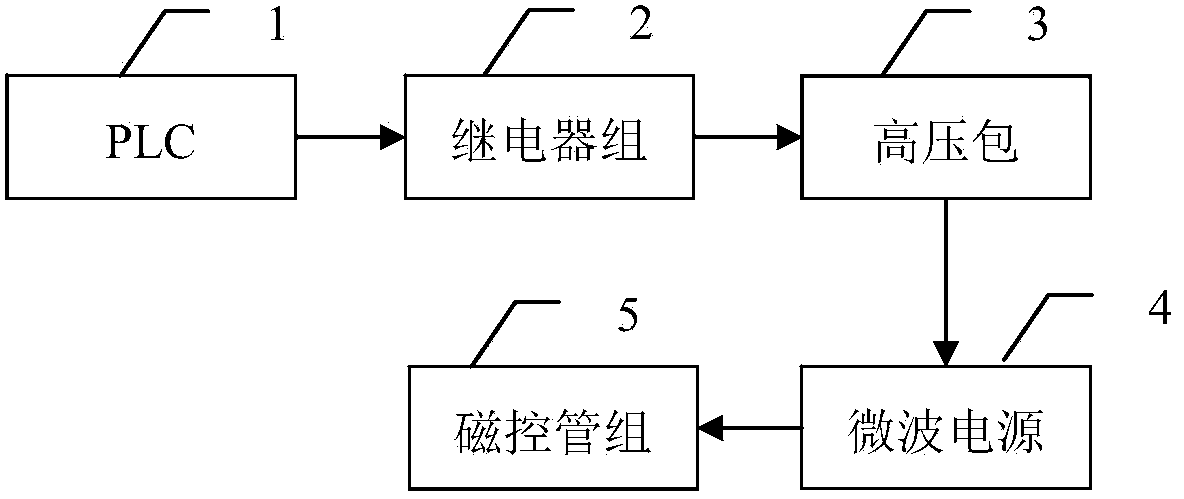

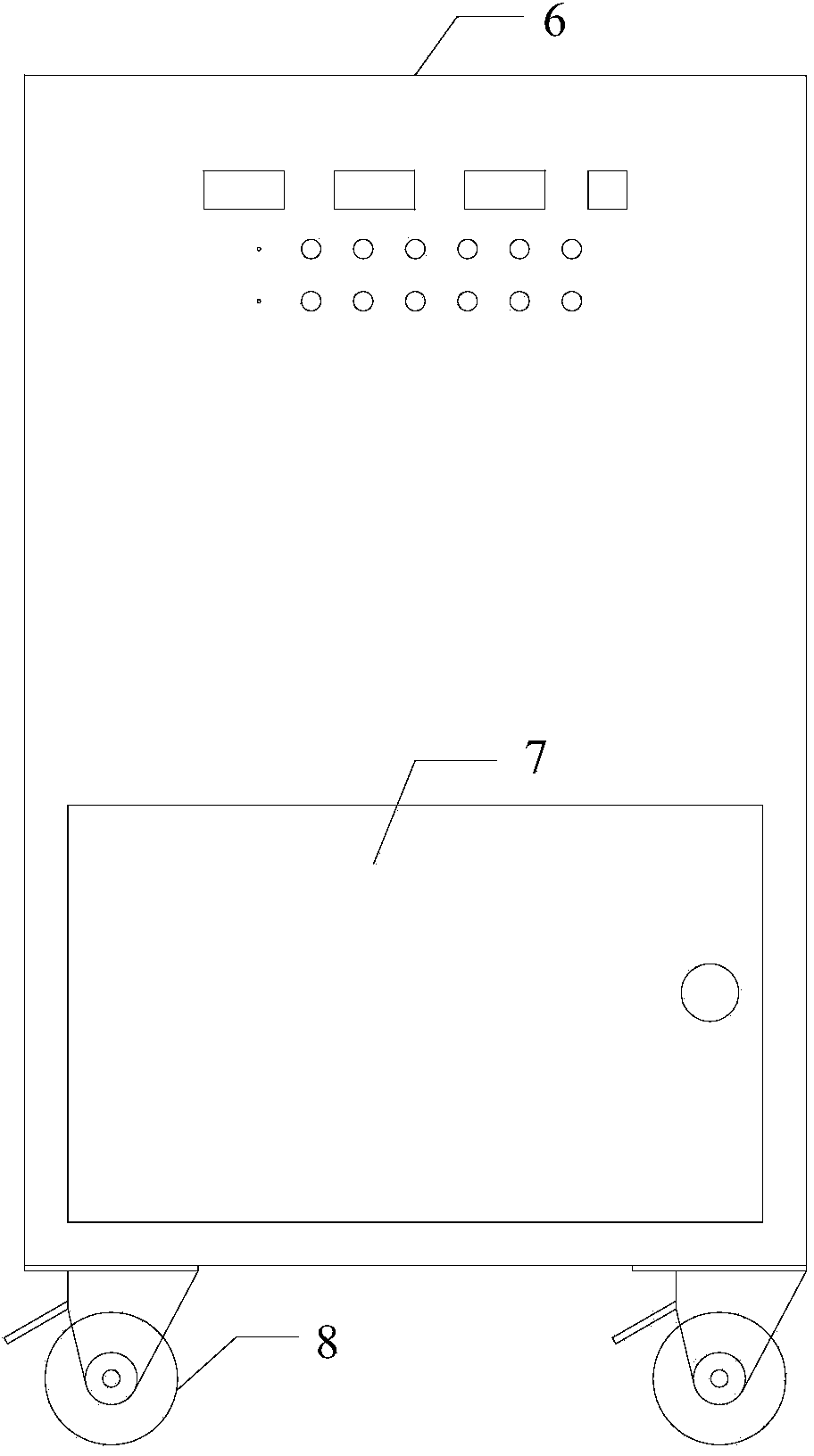

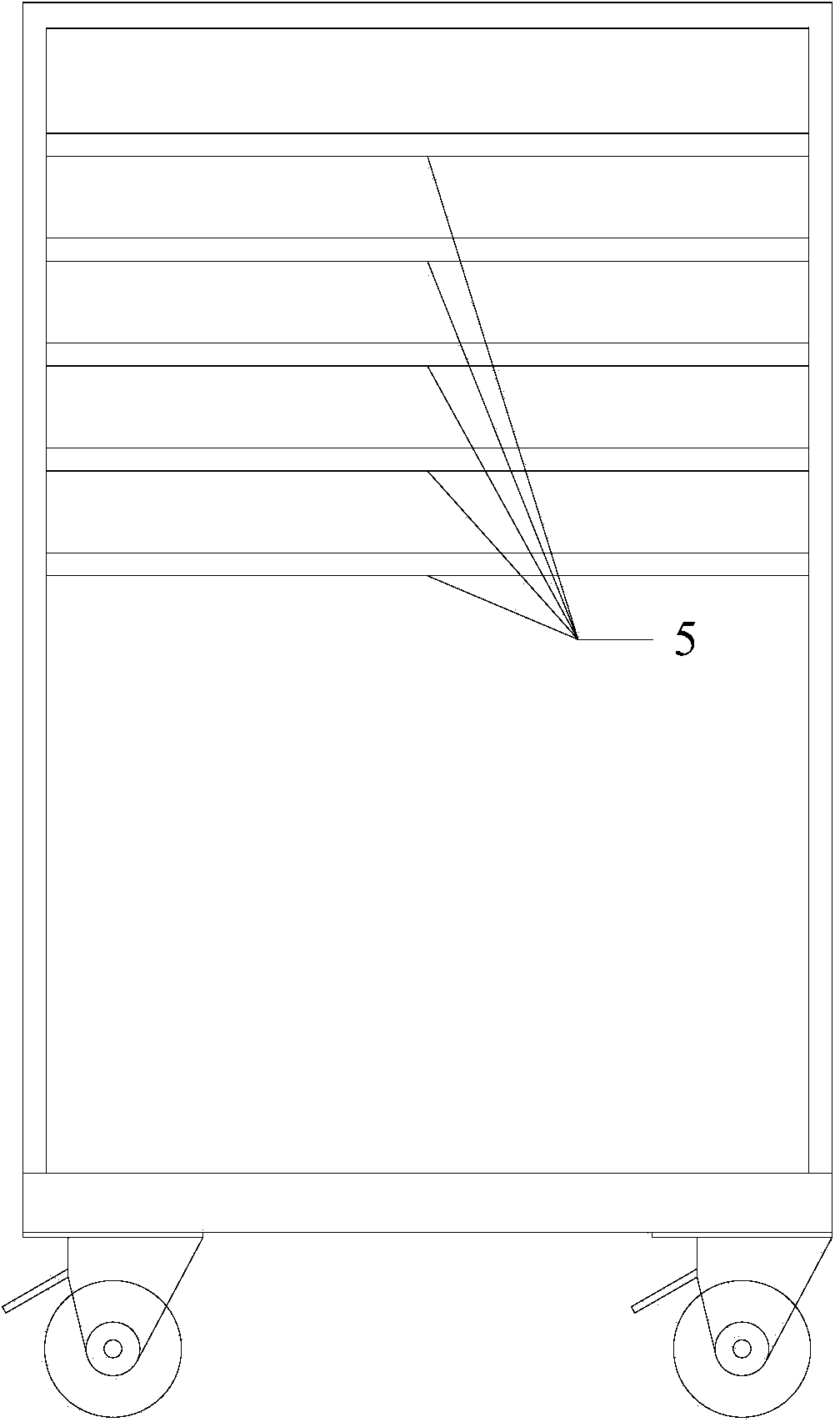

[0014] Specific implementation mode one: refer to figure 1 , figure 2 and image 3 Describe this embodiment in detail, the laboratory microwave deicer described in this embodiment, it comprises: PLC1, relay group 2, high voltage bag 3, microwave power supply 4, magnetron group 5, shell 6 and cavity door 7 ;

[0015] The current control signal output terminal of PLC1 is connected to the current control signal input terminal of relay group 2, the current signal output terminal of relay group 2 is connected to the current signal input terminal of high voltage package 3, and the voltage output terminal of high voltage package 3 is connected to the voltage input terminal of microwave power supply 4 terminal, the voltage output terminal of the microwave power supply 4 is connected to the voltage input terminal of the magnetron group 5;

[0016] A timing unit is embedded in PLC1;

[0017] The relay group 2 includes n relays, wherein n is a positive integer, the current control s...

specific Embodiment approach 2

[0021] Specific embodiment 2: This embodiment is a further description of the laboratory microwave deicer described in specific embodiment 1. In this embodiment, it also includes: m rollers 8, wherein m is a positive integer; m The rollers 8 are all fixed on the bottom of the shell 6 .

[0022] In this embodiment, adding rollers to the bottom of the laboratory microwave deicer can make it easy to move and easy to operate.

specific Embodiment approach 3

[0023] Specific embodiment three: this embodiment is to further explain the laboratory microwave deicer described in specific embodiment one. In this embodiment, it also includes: n indicator lights; n indicator lights are respectively connected in series to n Between the magnetrons and the microwave power supply 4, there are n indicator light openings on the casing 6, and the n indicator lights correspond to the n indicator light openings one by one and are embedded in the indicator light openings.

[0024] In this embodiment, n indicator lights are respectively connected in series between the n magnetrons and the microwave power supply 4 , which can intuitively show whether each magnetron is powered on and working. However, when any one of the magnetrons is damaged, the fault point can be quickly found.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com