Shielded flexible cables for robots

A shielded, flexible cable technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of anti-interference performance decline, signal interference, easy to generate static electricity, etc., to improve performance reliability and safety, and reduce the impact of structural changes , good insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

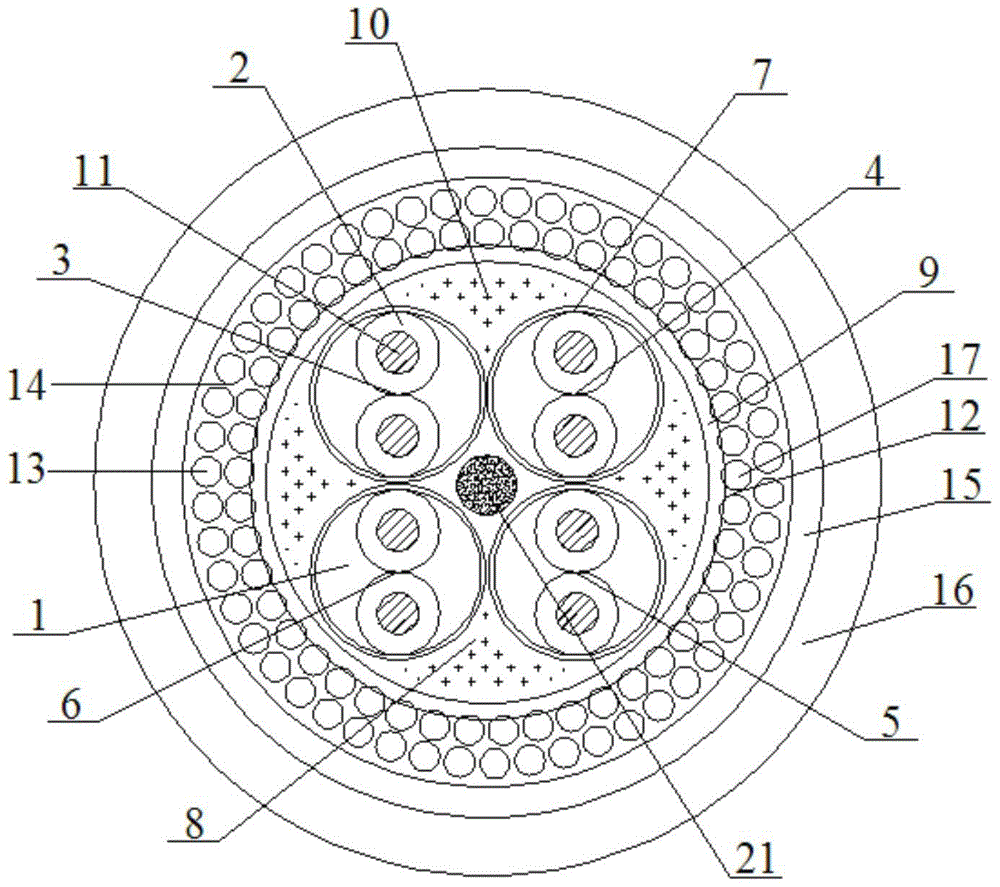

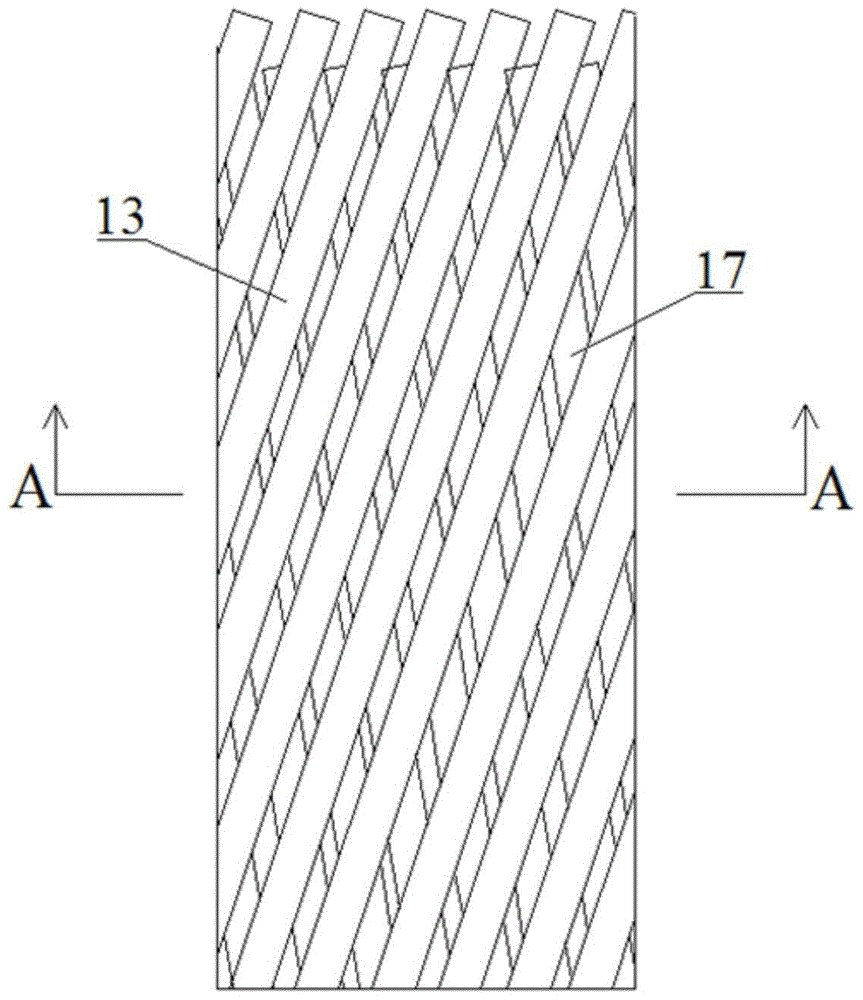

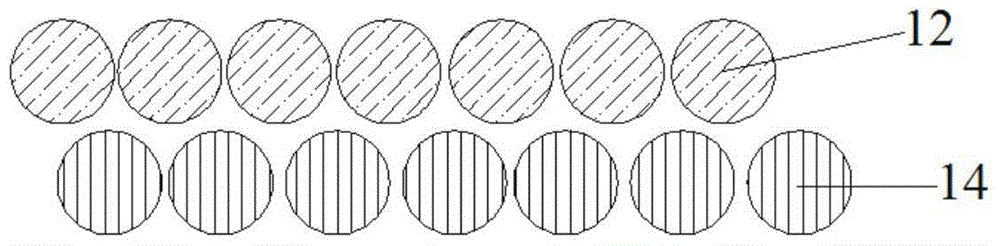

[0025] Embodiment: A shielded flexible cable for a robot, comprising: eight copper conductor units 1 and an aramid reinforcement 21, the outer surface of the copper conductor units 1 is covered with an insulating polypropylene layer 2, and the copper conductor units 1 include The aramid fiber 20 at the center, the inner conductive layer composed of a plurality of first copper wires 22 twisted on the outer surface of the aramid fiber 20, and the inner conductive layer formed by a plurality of second copper wires 23 twisted on the outer surface of the inner conductive layer. Conductor layer; the diameter of the aramid reinforcement 21 is 190-210D;

[0026] The eight copper conductor units 1 are twisted in pairs to form the first, second, third and fourth symmetrical insulated wire pairs 3, 4, 5, 6, and the outer surfaces of each are wrapped with a first polytetrafluoroethylene tape 7. The first, second, third and fourth symmetrical insulated wire pairs 3, 4, 5, 6 are stranded on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com