Multi-plane double glazing photovoltaic module and preparation technology thereof

A double-glass photovoltaic and photovoltaic module technology, applied in photovoltaic power generation, sustainable manufacturing/processing, electrical components, etc., can solve the problems of reducing the life of photovoltaic modules, low mismatch loss, power loss, etc., and achieve the reduction of maximum withstand current value, reducing the overall high current, and reducing the effect of mismatch loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

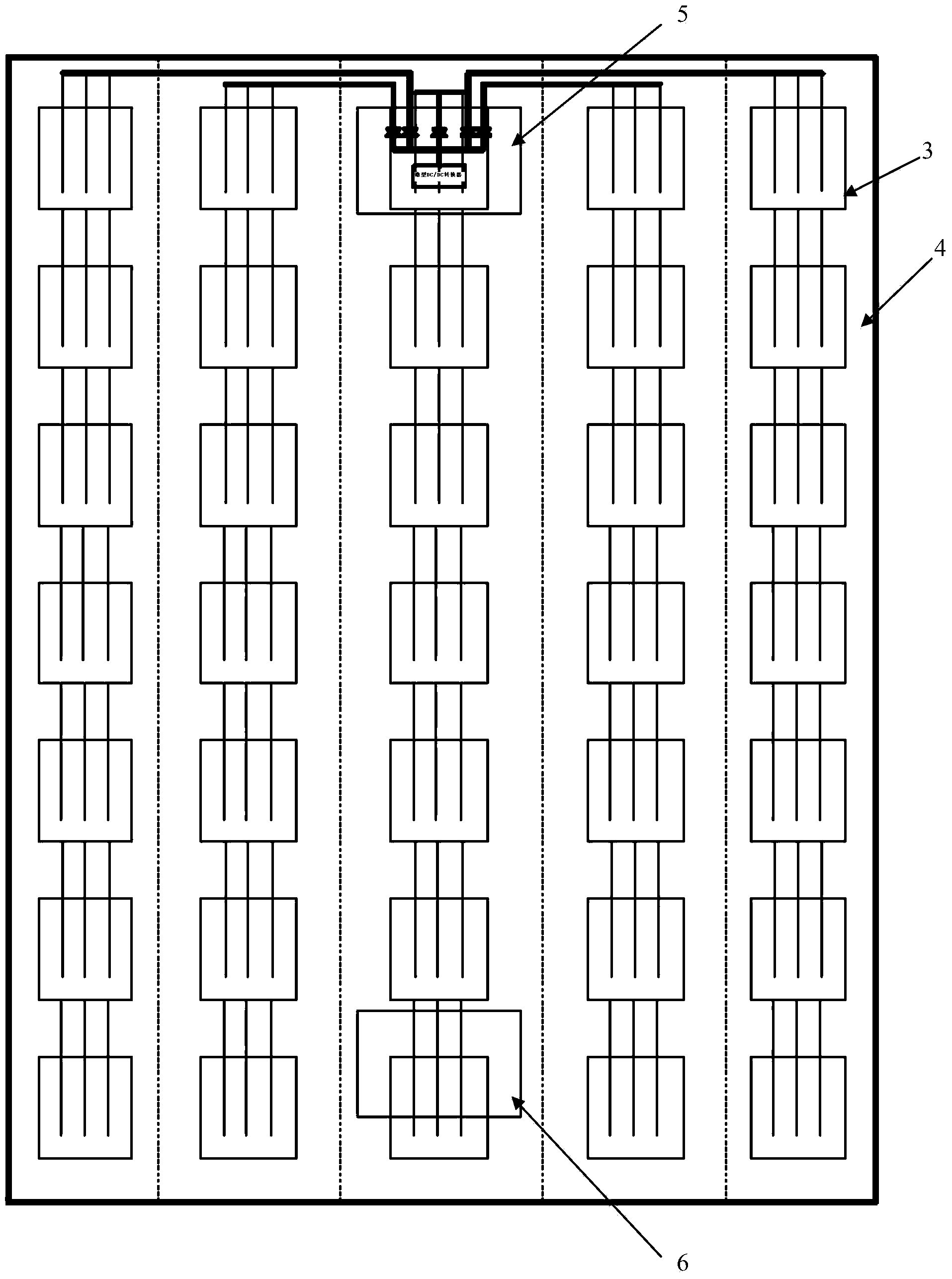

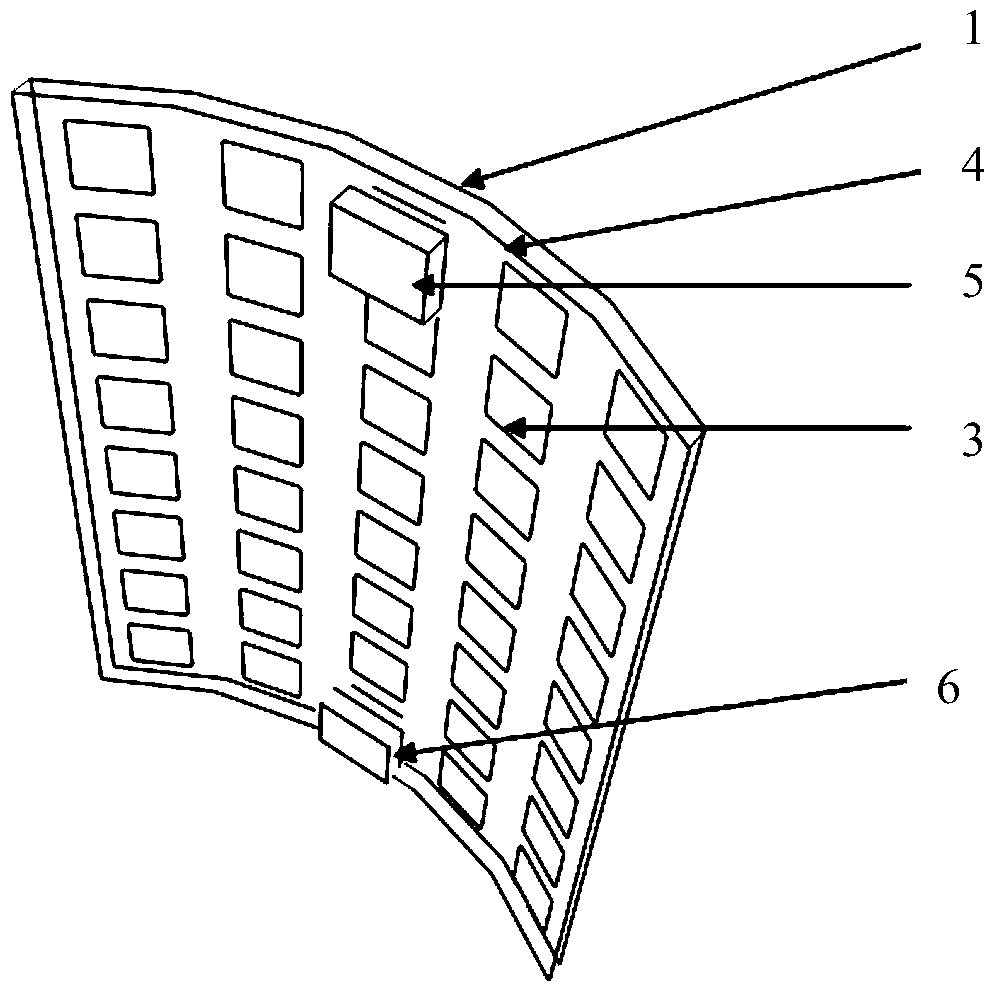

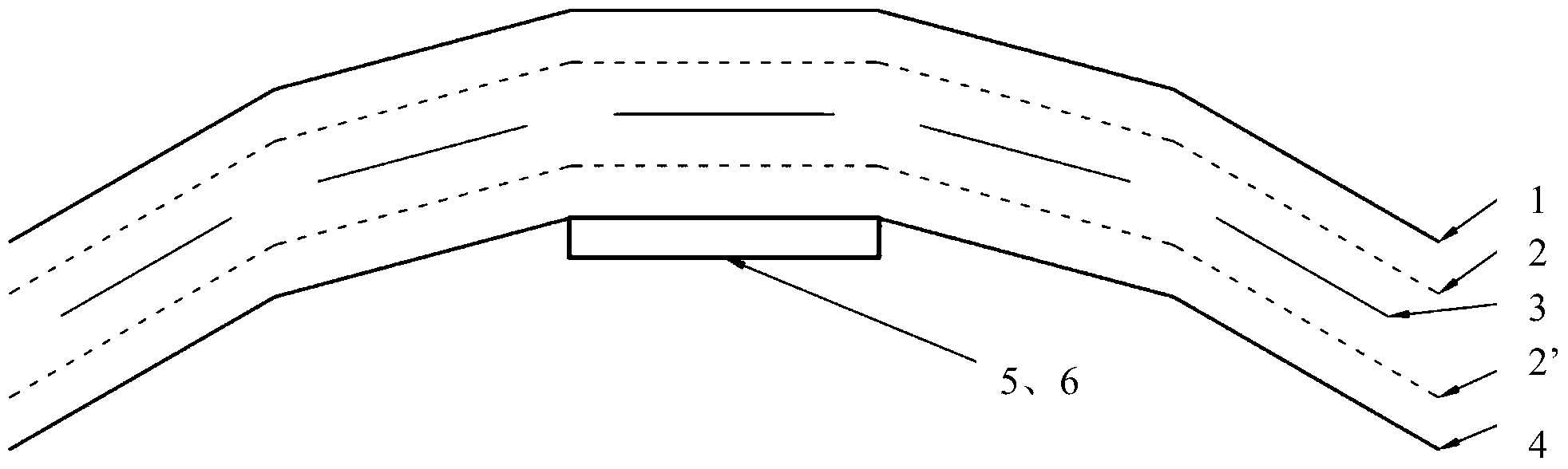

[0035] like Figure 1 to Figure 6 As shown, a multi-sided double-glass photovoltaic module according to the present invention includes a front cover glass 1, a first PVB film 2, several battery strings composed of a plurality of solar cells 3, and a second PVB film that are stacked in sequence. 2', the back glass 4 and the positive junction box 5 and the negative junction box 6 installed on the back of the back glass. A multi-plane glass plate structure with multiple planes, the solar battery slices 3 are placed on the plane positions of the glass plate structure correspondingly, and the solar battery slices 3 arranged on the same plane are connected in series to form a battery string, and the solar battery slices 3 on different planes The battery strings are connected in parallel in the positive junction box 5 and the negative junction box 6, the positive terminals of the battery strings are connected in parallel in the positive junction box 5 and then connected in series wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com