Sealed type switch cabinet

A switchgear, sealed technology, applied in the direction of pull-out switchgear, electric switch, switchgear, etc., can solve the complex manufacturing process, cannot meet the requirements of high-voltage switchgear's economy and reliability, and occupy Large space and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0147] The present invention will be further described in detail and completely below in conjunction with specific implementation methods and accompanying drawings.

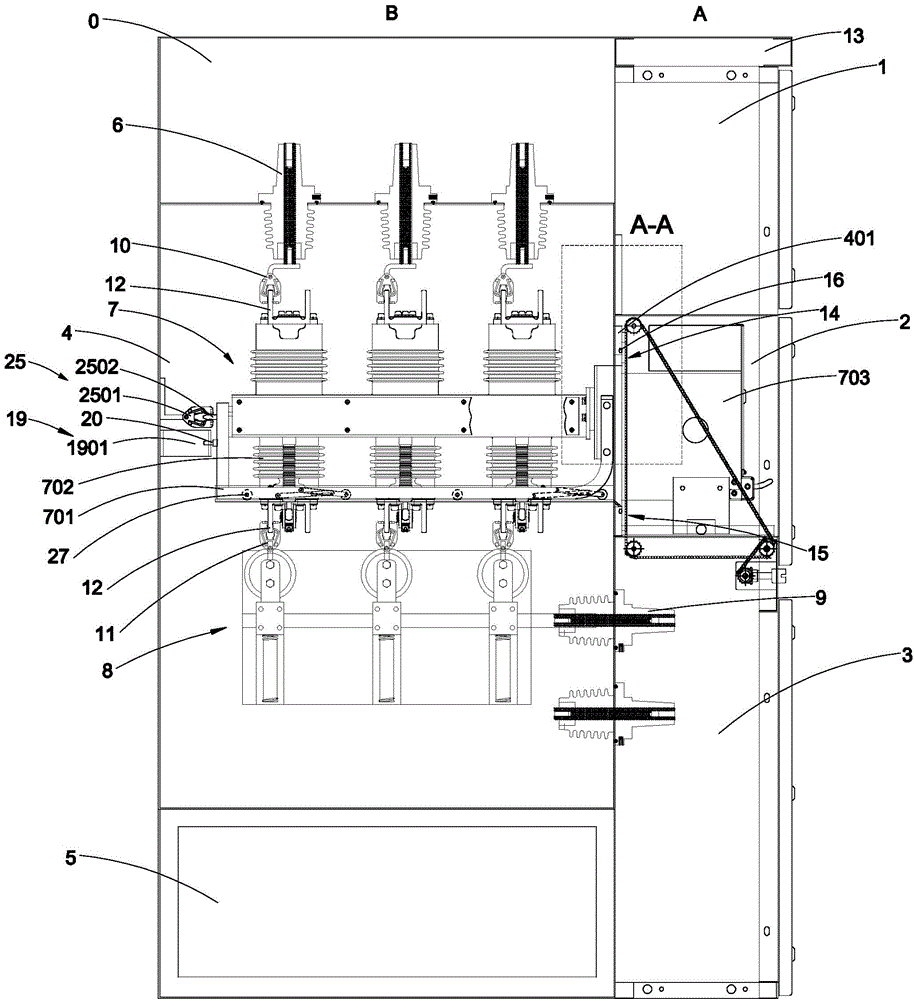

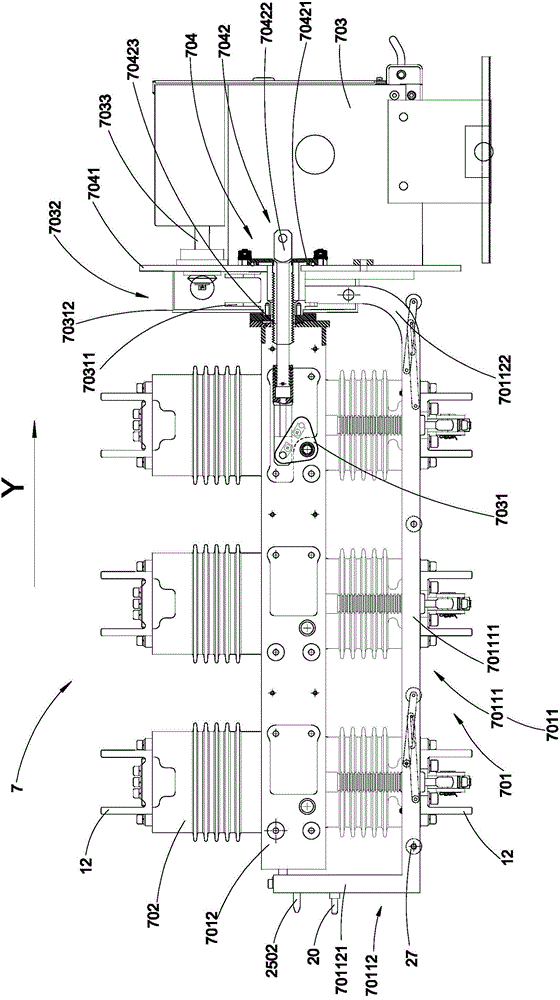

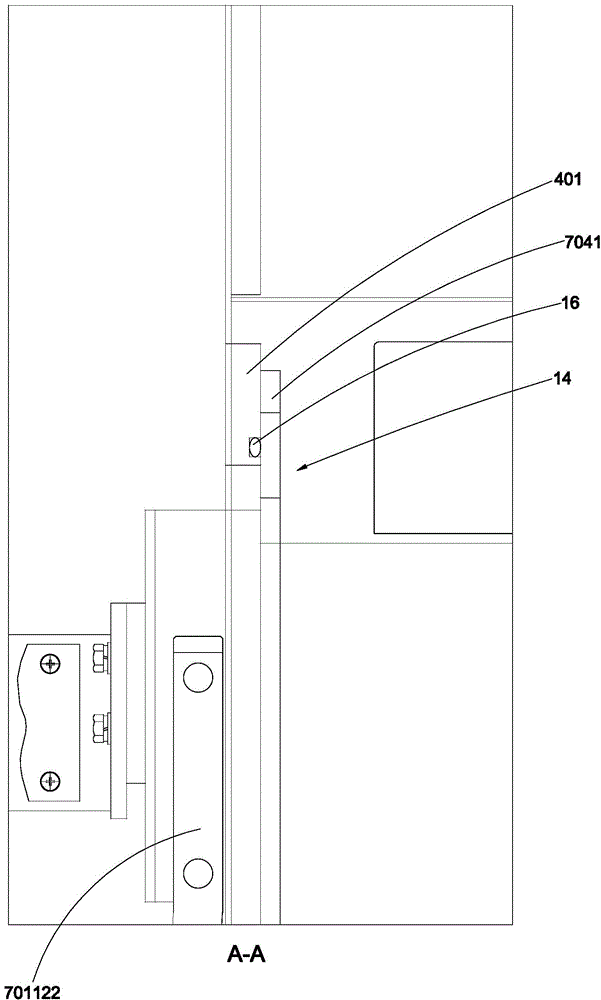

[0148] The invention provides a sealed switch cabinet, which is an indoor sealed switch cabinet, figure 1 It is a sectional view of a sealed switchgear, such as figure 1 As shown, the sealed switchgear is a floor-standing assembled cabinet structure, which includes busbar room 0, instrument room 1 (low voltage room), mechanism room 2, cable room 3, switch room 4 and pressure relief channel 5, specifically, the instrument room Room 1, mechanism room 2 and cable room 3 form the front cabinet A of the sealed switchgear, busbar room 0, switch room 4 and pressure relief channel 5 form the rear cabinet B of the sealed switch cabinet; front cabinet A and rear cabinet B The bottom is flush and placed on the ground or other planes, and the opposite cabinet walls of the front cabinet A and the rear cabinet B are attached ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com