Method for correcting position error of permanent magnet synchronous motor rotor based on linear hall

A technology of rotor position error and permanent magnet synchronous motor, which is applied to the control of generators, motor generators, electromechanical transmissions, etc., and can solve problems such as rotor position angle error, output signal distortion, and influence on control system performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

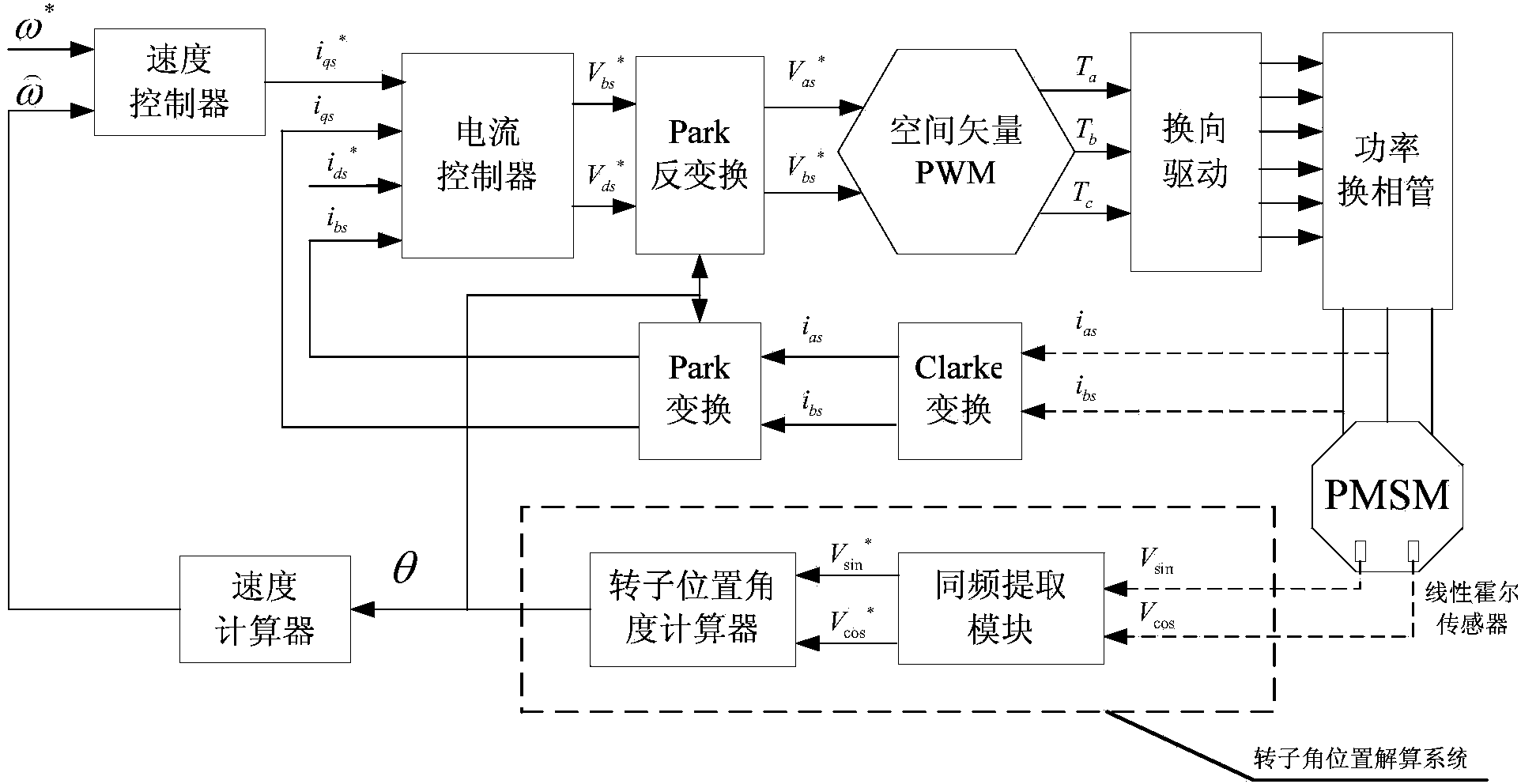

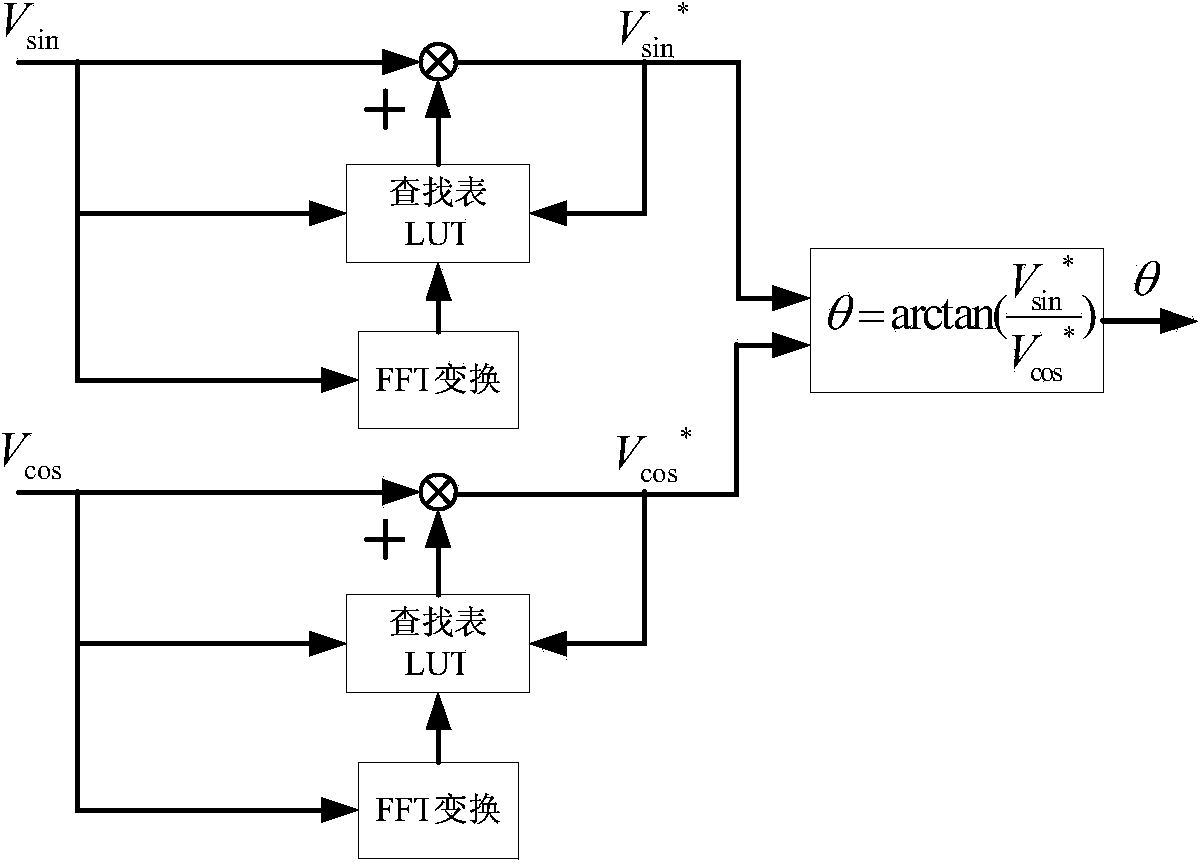

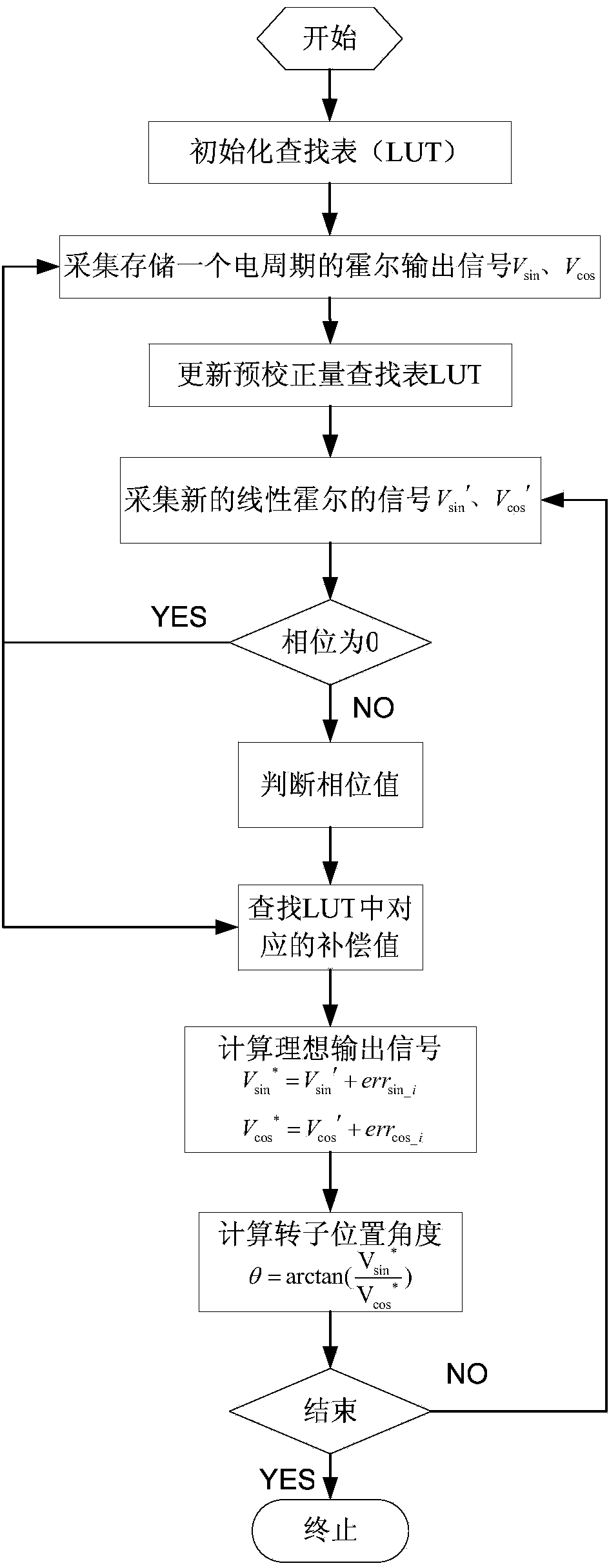

[0023] Such as figure 1 , 2 , 3, shown in 4, concrete method of the present invention is as follows:

[0024] (1) if figure 1As shown, the permanent magnet synchronous motor control system based on the linear Hall sensor to which the present invention is applicable includes two linear Hall sensors whose output signals differ by 90° from each other, and their output signals are respectively V sin , V cos , collect the two linear Hall output signals V sin and V cos As a raw linear Hall signal, the signal V for one electrical cycle is stored sin , V cos , after storage ends for V sin , V cos Perform FFT transformation respectively, and the transformed signal is:

[0025] V sin = A 1 sin θ + A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com