Preparation method of special zero-thans fatty acid plant fat powder for milk tea

A zero-trans, fatty acid technology, applied in the direction of edible oil/fat, application, food science, etc., can solve the problems that the microbial indicators of milk tea products exceed the national standards, and the total number of bacterial colonies of the finished product microbial indicators cannot be guaranteed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

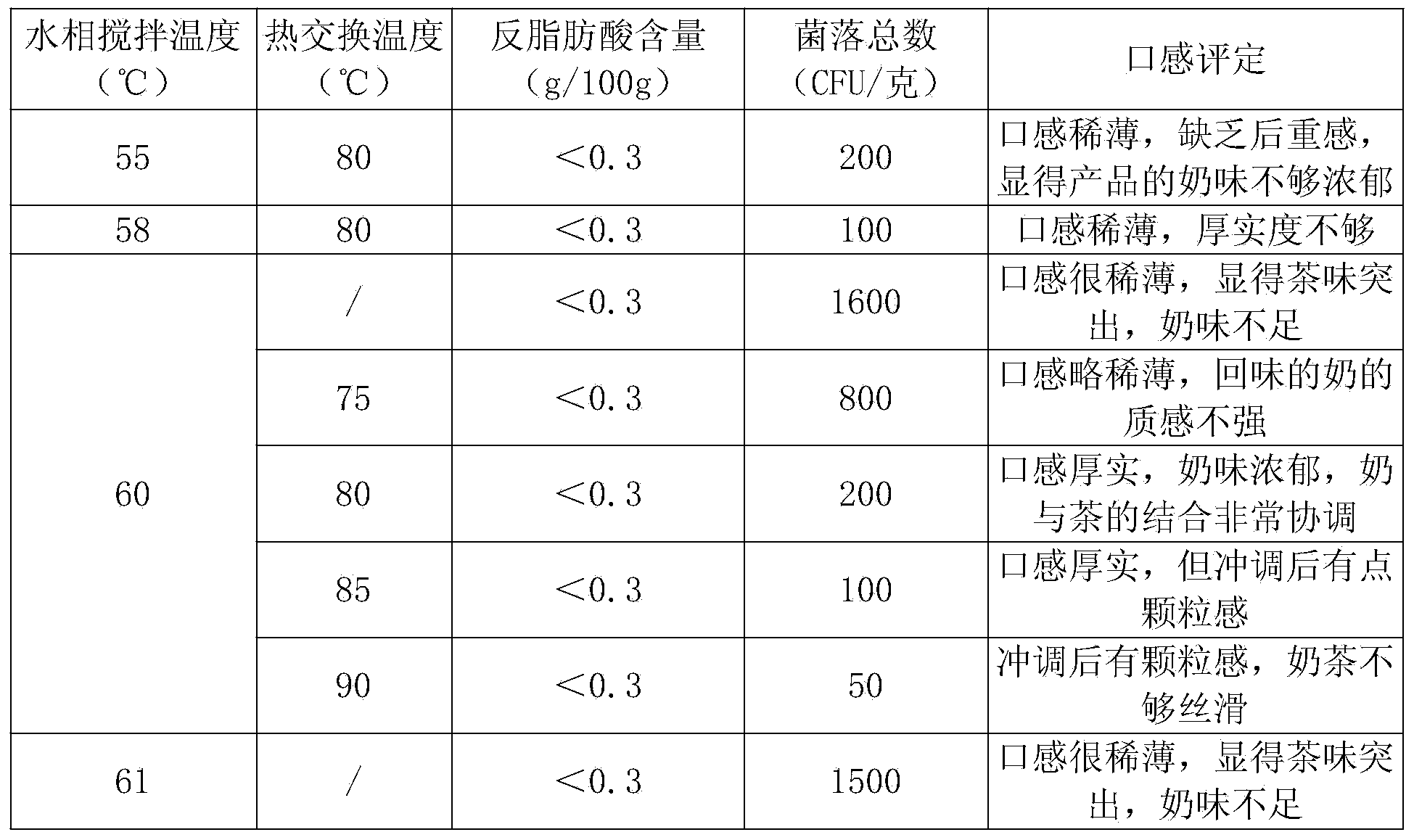

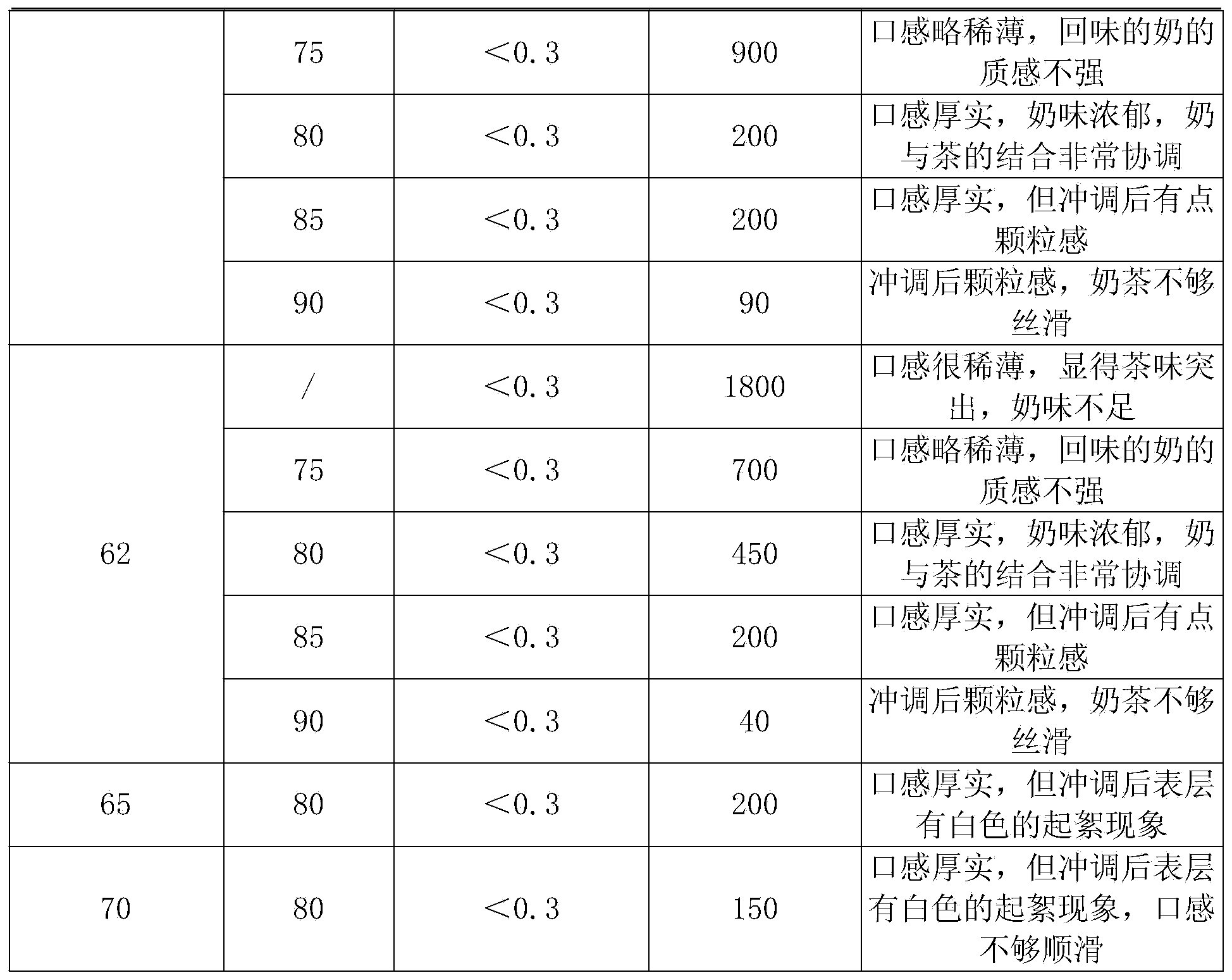

Method used

Image

Examples

Embodiment 1

[0024] Prepare raw materials by weight: 20 parts of process water, 1.3 parts of phosphate, 2 parts of concentrated whey protein powder, 17 parts of hydrogenated coconut oil, 0.5 part of edible emulsifier, and 40 parts of syrup.

[0025] Raise the temperature of the process water to 62°C, add phosphate and concentrated whey protein powder while stirring, raise the temperature to 60°C while stirring, and shear and stir at 50r / min for 10min to ensure that the protein is fully dissolved to obtain the water phase; the hydrogenated coconut Heat the oil to 70°C, add edible emulsifier while stirring until the edible emulsifier is completely dissolved to obtain an oil phase; heat the syrup to 40°C; stir the obtained water phase, oil phase and syrup at a stirring speed of 50r / min Mix evenly for 12 minutes, and then homogenize in a homogenizer at 57°C and 28MPa to obtain a feed liquid; the homogenized feed liquid is heat-exchanged for 30 seconds at a temperature of 82°C in a scraped-surfa...

Embodiment 2

[0027] Raw materials are prepared in parts by weight: 30 parts of process water, 1.5 parts of phosphate, 5 parts of concentrated whey protein powder, 20 parts of hydrogenated coconut oil, 1 part of edible emulsifier, and 50 parts of syrup.

[0028] Raise the temperature of the process water to 63°C, add phosphate and concentrated whey protein powder while stirring, raise the temperature to 62°C while stirring, and shear and stir at 53r / min for 15min to ensure that the protein is fully dissolved to obtain the water phase; the hydrogenated coconut Heat the oil to 80°C, and add edible emulsifier while stirring until the edible emulsifier is completely dissolved to obtain an oil phase; heat the syrup to 45°C; stir the obtained water phase, oil phase, and syrup at a stirring speed of 53r / min Mix evenly for 18 minutes, and then homogenize in a homogenizer at 60°C and 32MPa to obtain a feed liquid; the homogenized feed liquid is heat-exchanged for 40S at a temperature of 82°C in a scr...

Embodiment 3

[0030] Prepare raw materials by weight: 25 parts of process water, 1.4 parts of phosphate, 4 parts of concentrated whey protein powder, 18 parts of hydrogenated coconut oil, 08 parts of edible emulsifier, and 45 parts of syrup.

[0031] Raise the temperature of the process water to 62°C, add phosphate and concentrated whey protein powder while stirring, raise the temperature to 61°C while stirring, and shear and stir at 52r / min for 13min to ensure that the protein is fully dissolved to obtain the water phase; the hydrogenated coconut Heat the oil to 75°C, and add edible emulsifier while stirring until the edible emulsifier is completely dissolved to obtain an oil phase; heat the syrup to 43°C; stir the obtained water phase, oil phase, and syrup at a stirring speed of 52r / min Mix evenly for 15 minutes, and then homogenize in a homogenizer at 58°C and 30MPa to obtain a feed liquid; the homogenized feed liquid is heat-exchanged for 40S at a temperature of 80°C in a scraped-surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com