Preparation method of crisp chestnut kernel and product thereof

A technology for chestnut kernels and crispy, applied in the field of preparation of crispy chestnut kernels, can solve the problems of many processing steps and complicated processes, and achieve the effects of low production energy consumption, improved safety quality, and sweet taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

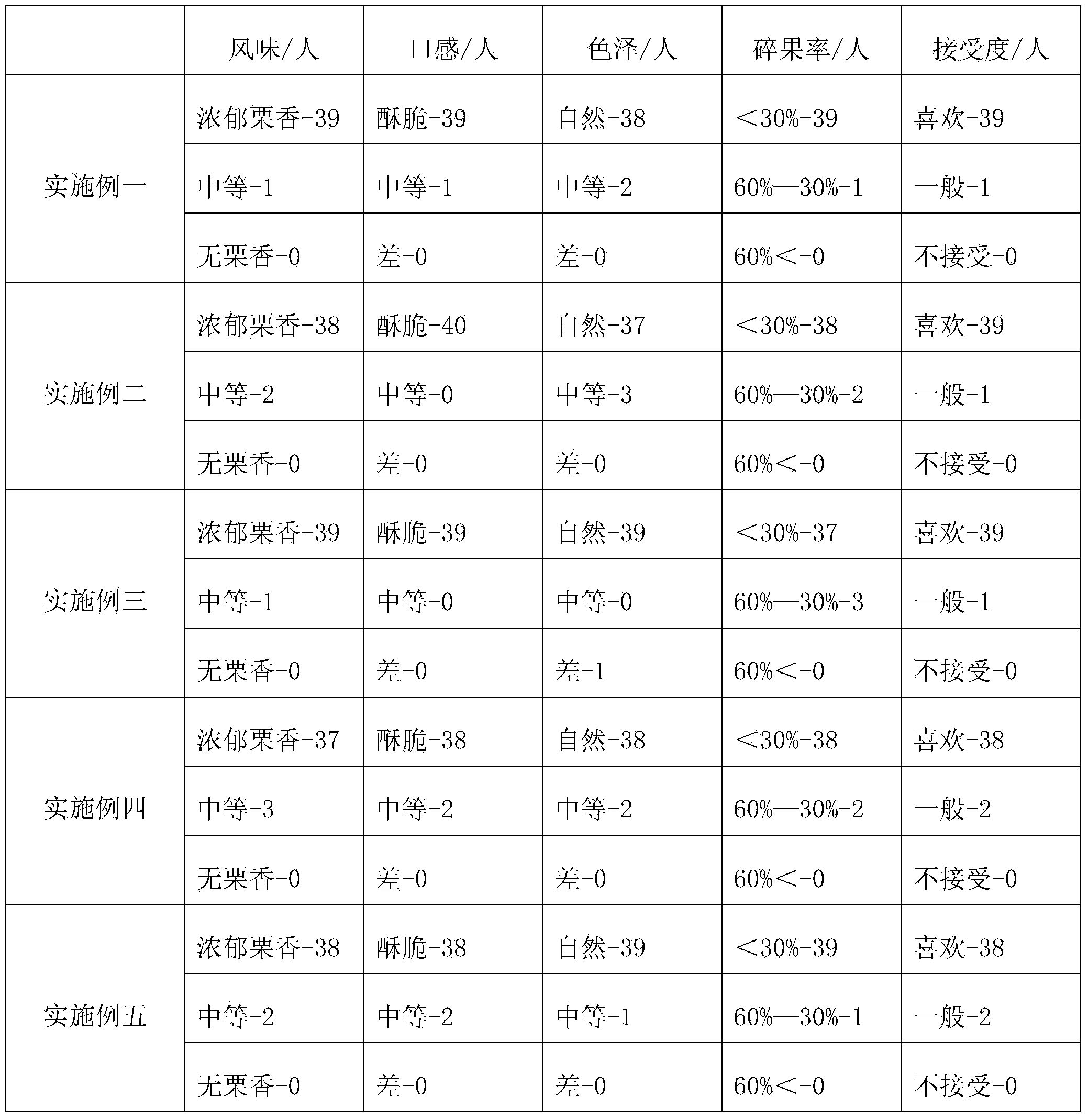

Examples

Embodiment 1

[0026] A preparation method for crispy chestnut kernels, comprising the following steps,

[0027] (1) Raw material screening: select clean fresh chestnuts, and get chestnut kernels after shelling;

[0028] (2) Steaming: steaming the chestnut kernels obtained in step (1) at 90°C for 60 minutes;

[0029] (3) Pre-drying: pre-drying the chestnut kernels obtained in step (2) in hot air at 60°C until the moisture content reaches 60%;

[0030] (4) High-pressure treatment: put the chestnut kernels obtained in step (3) into a high-pressure tank, vacuumize and flush into 0.5MPa high-pressure carbon dioxide permeation treatment for 60 minutes;

[0031] (5) Vacuum drying: the chestnut kernels obtained in step (4) are placed in a vacuum drying device at 50°C and vacuum-dried until the water content is 5%, to obtain crispy chestnut kernels.

Embodiment 2

[0033] A preparation method for crispy chestnut kernels, comprising the following steps,

[0034] (1) Raw material screening: select clean fresh chestnuts, and get chestnut kernels after shelling;

[0035] (2) Steaming: steaming the chestnut kernels obtained in step (1) at 100°C for 30 minutes;

[0036] (3) Pre-drying: pre-drying the chestnut kernels obtained in step (2) in hot air at 80°C until the moisture content reaches 20%;

[0037] (4) High-pressure treatment: after putting the chestnut kernels obtained in step (3) into a high-pressure tank, vacuumize and flush into 10.0MPa high-pressure nitrogen gas permeation treatment for 30 minutes;

[0038] (5) Vacuum drying: put the chestnut kernels obtained in step (4) in a vacuum drying device at 80°C and vacuum-dry until the water content is 3%, to obtain crispy chestnut kernels.

Embodiment 3

[0040] A preparation method for crispy chestnut kernels, comprising the following steps,

[0041] (1) Raw material screening: select clean fresh chestnuts, and get chestnut kernels after shelling;

[0042] (2) Steaming: steam the chestnut kernels obtained in step (1) for 40 minutes in water vapor at 95°C;

[0043] (3) Pre-drying: pre-drying the chestnut kernels obtained in step (2) in hot air at 70°C until the moisture content reaches 40%;

[0044] (4) High-pressure treatment: Put the chestnut kernels obtained in step (3) into a high-pressure tank, vacuumize and flush into 5.0MPa high-pressure carbon dioxide permeation treatment for 40 minutes;

[0045] (5) Vacuum drying: the chestnut kernels obtained in step (4) were placed in a vacuum drying oven at 70° C. and vacuum-dried until the water content was 6%, to obtain crispy chestnut kernels.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com