Water-absorbing oil-repellent fabric and production method

A production method and fabric technology, applied in the direction of plant fibers, etc., can solve problems such as complex methods and affect wearing comfort, and achieve the effects of simple and easy manufacturing methods, easy and fast washing, and excellent water absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Select polyester-cotton T / C (80 / 20) interwoven fabric as the base fabric (undyed product), and carry out the following processes in sequence to obtain the product.

[0036] (1) Treatment in the bath

[0037] ① Formula

[0038] Water-dispersible polyester resin 2%owf

[0039] Bath ratio 1:20

[0040] ②Process flow

[0041] Normal temperature → 2°C / min heating to 100°C for 20 minutes → 2°C / min cooling to 50°C → 130°C drying for 2 minutes;

[0042] (2) Padding processing

[0043] ① Formula

[0044] Carbon 6 fluorine resin 20g / l

[0045] Water-dispersible polyester resin 30g / l

[0046] ②Process flow

[0047] Padding (one dipping and one rolling, the remaining rate is 80%)→drying (130℃×2min)→setting (170℃×1min).

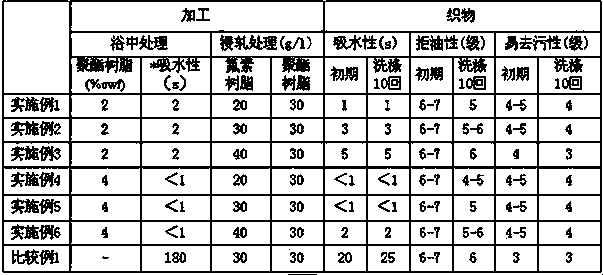

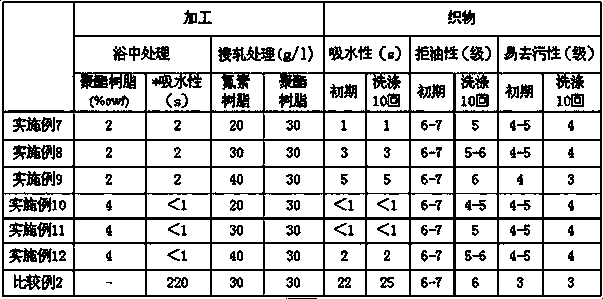

[0048] The various properties of the obtained water-absorbent and oil-repellent fabric are shown in Table 1.

Embodiment 2

[0050] Padding Processing Formula

[0051] Carbon 6 fluorine resin 30g / l

[0052] Water-dispersible polyester resin 30g / l

[0053] All the other conditions are the same as in Example 1.

[0054] The various properties of the obtained water-absorbent and oil-repellent fabric are shown in Table 1.

Embodiment 3

[0056] Padding Processing Formula

[0057] Carbon 6 fluorine resin 40g / l

[0058] Water-dispersible polyester resin 30g / l

[0059] All the other conditions are the same as in Example 1.

[0060] The various properties of the obtained water-absorbent and oil-repellent fabric are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com