Heat-transfer equipment performance experimental facility

An experimental device and heat transfer equipment technology, which is applied in the field of heat transfer equipment performance experimental devices to achieve the effect of efficient heat recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

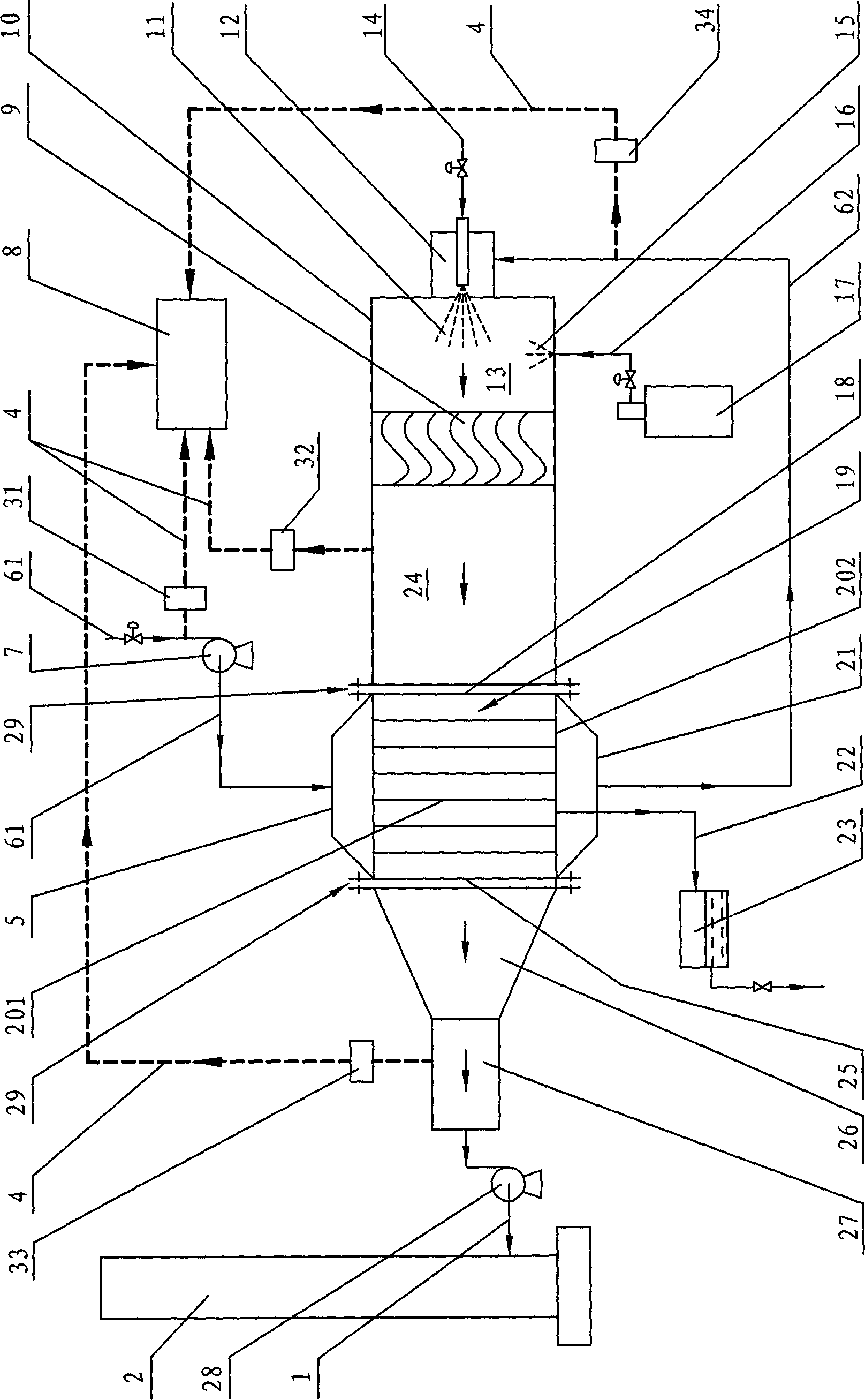

[0008] see figure 1 , the heat transfer equipment performance experimental device (abbreviated as the experimental device) of the present invention is used to conduct experiments on the heat transfer performance, corrosion resistance and mechanical properties of the air preheater 19 for gas-gas heat transfer, and the air preheater 19 installed on the experimental setup. figure 1 The air preheater 19 shown is a tubular air preheater, and is provided with heat transfer tubes 201; multiple heat transfer tubes 201 are provided to form a tube bundle. The present invention requires that the heat transfer tube 201 be arranged vertically, the air inlet 5 of the air preheater is located at the top, the air outlet 21 of the air preheater is located at the bottom, and the flue gas inlet 18 of the air preheater and the flue gas outlet 25 of the air preheater are located at the side . The air preheater 19 can also be a plate-type air preheater, provided with heat transfer plates; the pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com