High-power microchip laser device

A microchip laser, high-power technology, applied in the direction of lasers, laser components, phonon exciters, etc., can solve the problems of demanding laser stability, easy loss of coupling, waste of resources, etc., to facilitate the adaptation between mode fields effect, improve coupling efficiency, and improve stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The features of the present invention and other related features will be further described in detail below in conjunction with the accompanying drawings through embodiments, so as to facilitate the understanding of those skilled in the art:

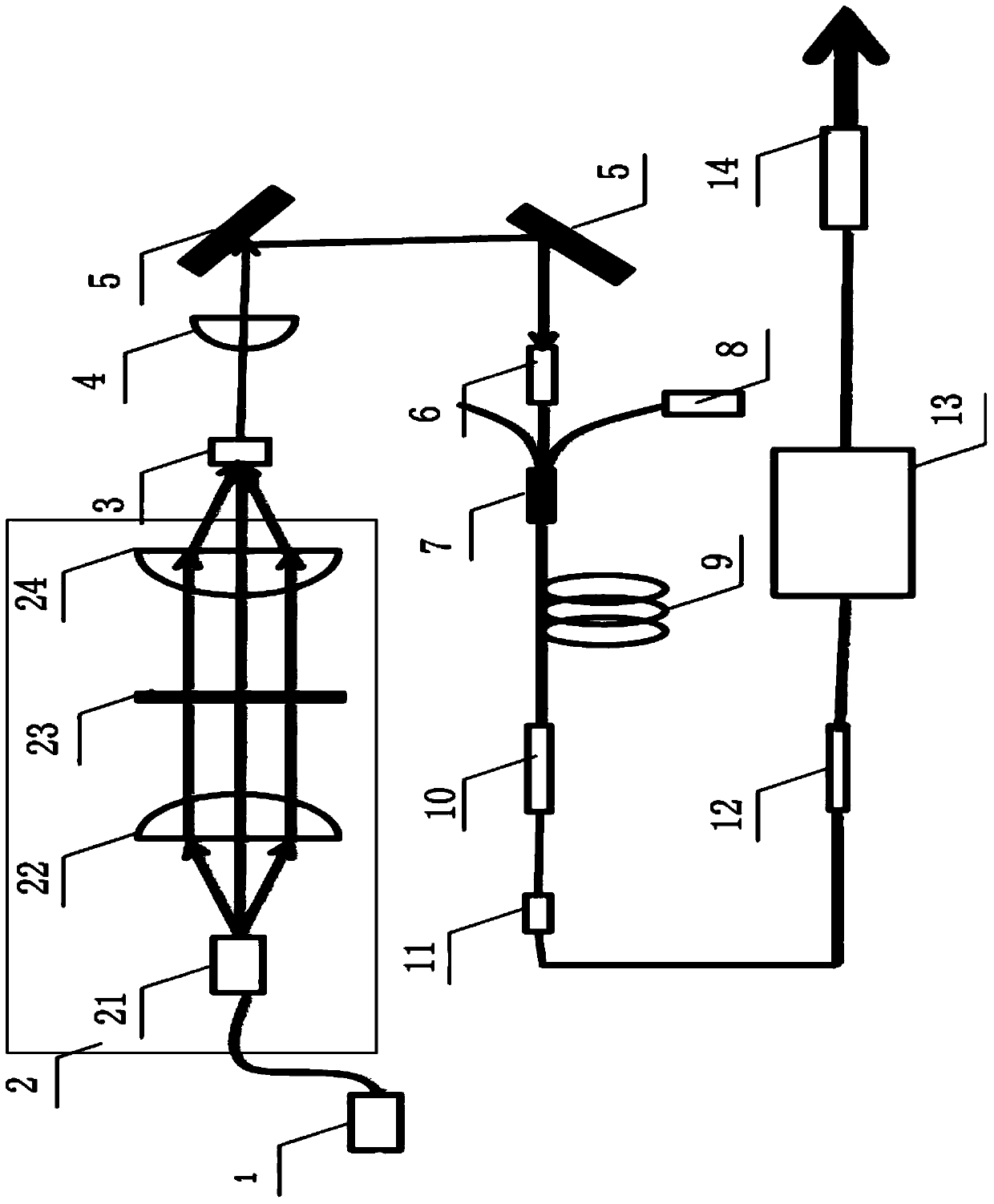

[0023] Such as figure 1 As shown, a high-power microchip laser device includes a first pump light source 1 connected in sequence, an optical coupling system 2, a passive Q-switched microchip 3, a convex lens 4 for focusing output, a reflector 5, and a first A collimator 6 and a beam combiner 7, the beam combiner 7 is provided with a collimation input end, a pump light input end, and a beam combination output end, and the beam combiner 7 collimates the input end and the first collimator The output end of the beam combiner 6 is connected to the output end of the beam combiner 7, and the pump light input end of the beam combiner 7 is connected to a second pump light source 8, and the output end of the beam combiner 7 is connected to a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Core diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com