Electromagnetic Steel Sheet

A technology of electromagnetic steel plate and steel plate, applied in the direction of circuits, magnetic objects, magnetic materials, etc., can solve the problem of reducing the limit of plate thickness, and achieve the effect of excellent iron loss characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

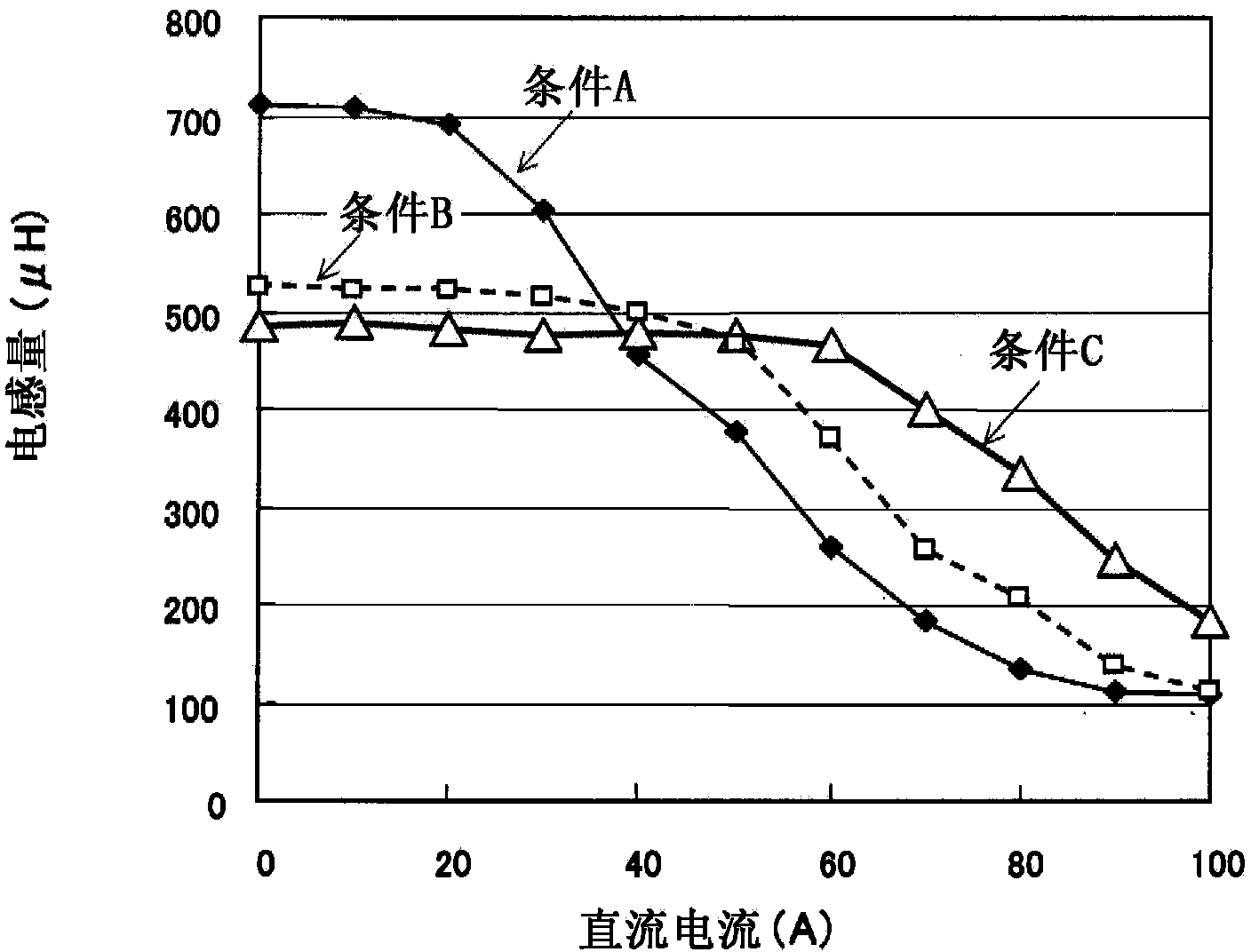

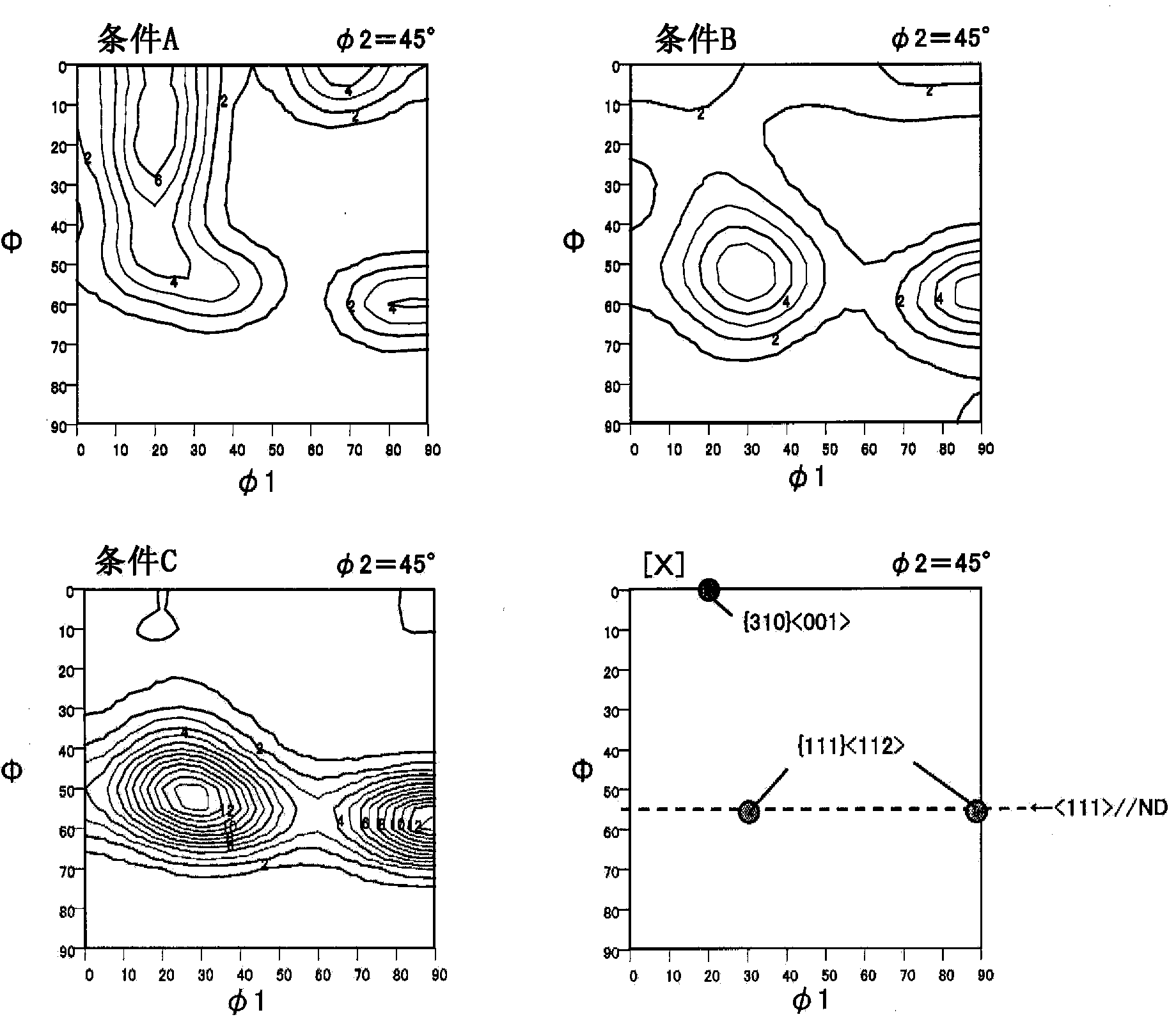

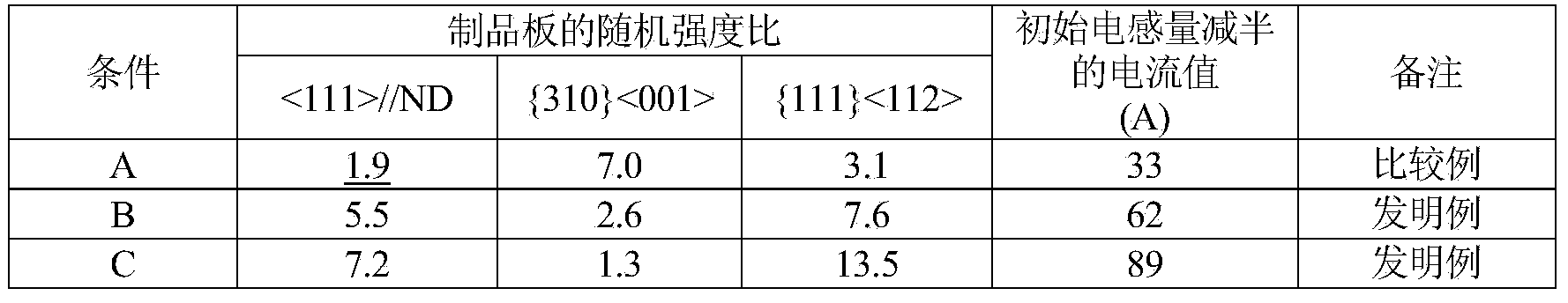

Embodiment 1

[0071] Melting steel containing C: 0.0047% by mass, Si: 1.24% by mass, Mn: 0.15% by mass, and the balance consisting of Fe and unavoidable impurities is melted, continuous casting is made into a slab, and the slab is heated Hot rolling was performed at 1220° C. to obtain a hot-rolled sheet having a thickness of 1.8 mm. Next, this hot-rolled sheet was made into a cold-rolled sheet having a final sheet thickness of 0.10 mm under the following three conditions.

[0072] A: After the hot-rolled sheet is annealed at 1050°C for 75 seconds, the intermediate plate thickness is 1.0mm by the first cold rolling, and after the intermediate annealing at 1000°C for 30 seconds, the second pass Cold rolling was performed to obtain a cold-rolled sheet having a final sheet thickness of 0.10 mm.

[0073] · B: After performing hot-rolled sheet annealing at 1050° C.×75 seconds on the hot-rolled sheet, cold-rolled sheet having a final sheet thickness of 0.10 mm was obtained by one pass of cold rol...

Embodiment 2

[0082] A steel containing Si in the range of Si: 1.1 to 4.5% by mass, other components in the amounts listed in Table 2, and the balance consisting of Fe and unavoidable impurities was melted and continuously cast to form a slab. The slab was heated to 1200° C., hot-rolled to form a hot-rolled sheet with a thickness of 1.8 mm, pickled to remove scale, and then cold-rolled once to obtain a cold-rolled sheet with a final thickness of 0.10 mm. After that, in 15 vol% SiCl 4 +85vol%N 2 A siliconizing treatment (final annealing) was performed at 1150° C. for 300 seconds in an air atmosphere. Among them, the steel plate No.2 in Table 2 is 100 volume% N 2 Gas is the atmosphere for final annealing, and siliconizing treatment is not performed. In addition, the Si concentrations of the steel sheets after the siliconizing treatment were all substantially uniform in the thickness direction, and the Si amounts are shown in Table 2 together. In addition, for the sake of caution, componen...

Embodiment 3

[0089] For components containing C: 0.0062 mass%, Si: 2.09 mass%, Mn: 0.08 mass%, P: 0.011 mass%, Cr: 0.03 mass% and Sb: 0.035 mass%, the balance is composed of Fe and unavoidable impurities The composed steel was smelted and continuously cast to form a slab, and the slab was heated to 1150° C. and hot-rolled to obtain a hot-rolled sheet having a thickness of 2.2 mm. Next, pickling was performed to remove scale, and cold rolling was performed once to obtain a cold-rolled sheet having a final thickness of 0.10 mm. After that, in 10 vol% SiCl 4 In an atmosphere of +90% by volume Ar gas, perform a siliconizing treatment (final annealing) at 1200°C for 30 seconds, and change the Si concentration gradient in order to further promote the diffusion of Si into the interior. 2 Diffusion annealing at 1200° C. for the time shown in Table 3 was performed in an atmosphere. However, since the siliconizing treatment conditions were the same for all the steel sheets, the Si concentration av...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com