High heat dissipation type inductor

A technology with high heat dissipation and inductance, applied in the field of inductance, it can solve the problems of thermal aging, low DC superposition characteristics, overheating use, etc., and achieve the effects of high toughness and bonding strength, excellent DC superposition characteristics, and high heat resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

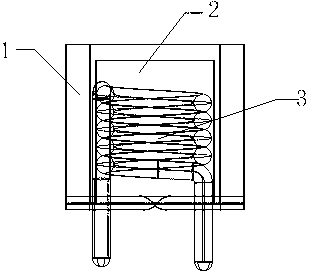

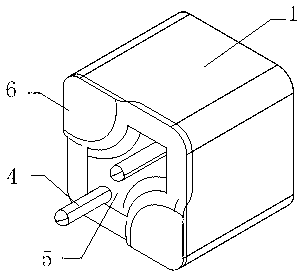

[0014] Such as figure 1 , figure 2 The high heat dissipation inductor shown includes an inductor core body 1 , which is different in that: the inductor core body 1 used in the present invention is provided with an accommodating space 2 . Specifically, a wire pack assembly 3 is provided in the accommodation space 2, and the accommodation space 2 is filled with alloy powder. At the same time, the pins 4 of the wire package assembly 3 and the heat dissipation structure are arranged at the bottom of the inductor core body 1 .

[0015] As far as a preferred embodiment of the present invention is concerned, in order to facilitate effective heat dissipation during work, increase the heat dissipation ratio, and reduce the temperature of the inductor, the heat dissipation structure is a heat dissipation groove 5 . At the same time, in consideration of unnecessary obstruction to the cooling slot 5 after the inductor is installed in place, there are cooling bumps 6 distributed at the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com