Distributor and distillation device with same

A technology of distillation device and distributor, which is applied in the field of distributor and distillation device, can solve problems such as insufficient contact of gas phase components, failure to achieve heat exchange, mass transfer effect, and influence on separation accuracy, so as to avoid channeling, Easy to control and improve the effect of separation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

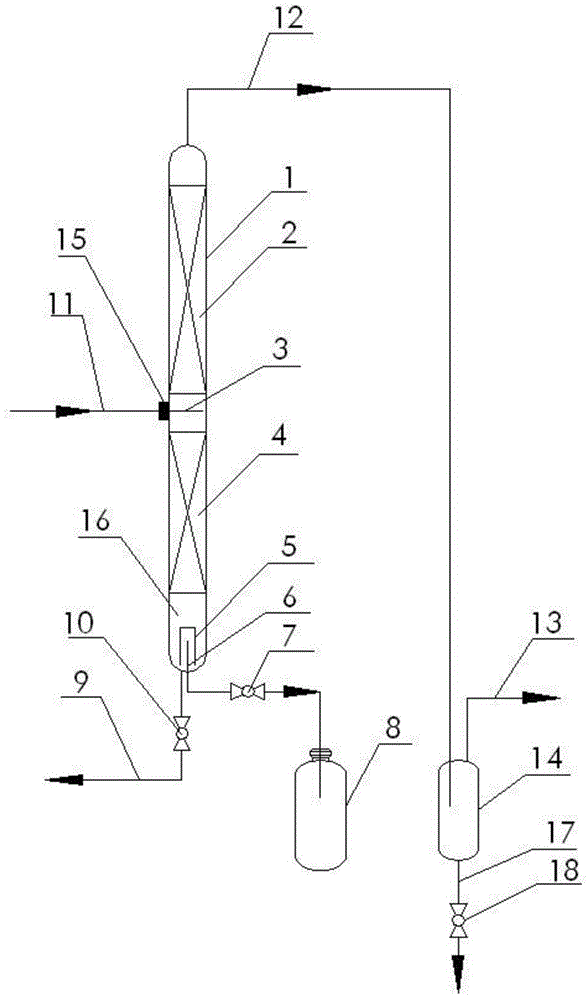

[0036] Distributor proposed by the present invention, when in use, such as figure 1 , 2 As shown, when the experimental device is tested, the following operations can be performed:

[0037] (1) Before starting work, check the distillation unit comprehensively;

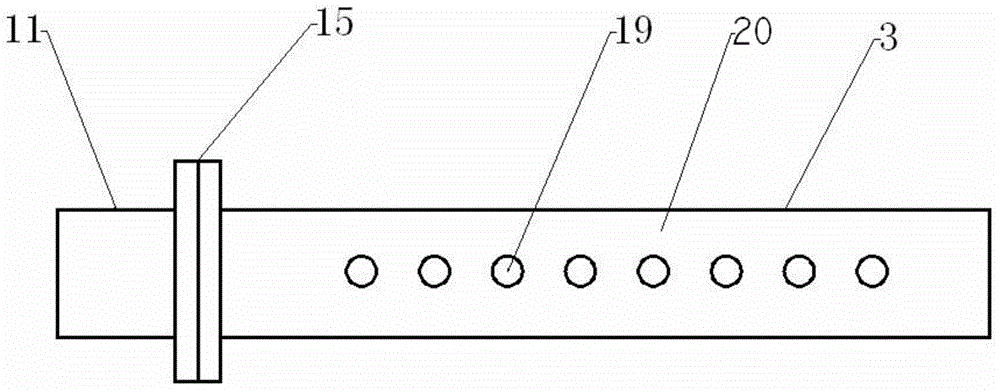

[0038] (2) Distributor 3 is connected with feed line 11 with quick connector 15;

[0039] (3) The raw material oil enters the distributor 3 from the feed line 11, then sprays downwards from a plurality of discharge holes 19, fully contacts with the stripping section 4 and the vaporized gas phase components from the reboiler 16, and performs heat exchange and mass transfer to achieve the purpose of separating light and heavy components;

[0040] (4) When the distributor needs to be replaced, remove the quick connector 15 and take out the distributor 3;

[0041] (5) Insert a new distributor into the distillation column, install it with the discharge port facing down, and connect it with the feed line 11 with a quick ...

Embodiment 2

[0043] A certain oil product is continuously distilled through 3 distillation towers (all equipped with the distributor of the present invention), and 4 fractions are separated. The product is ejected from tower 1 (T1), and the bottom of the tower enters tower 2 (T2) to continue distillation; the product is ejected from tower 2 (T2), and the bottom of the tower enters tower 3 (T3) to continue distillation; both the top and bottom of tower 3 (T3) come out product. The distillation range data of the 4 products are listed in Table 1.

[0044] Table 1 Distillation range of T1 ~ T3 distillation test products

[0045] product number

T1 top

T2 top

T3 top

T3 bottom

Distillate mass, %

temperature, ℃

temperature, ℃

temperature, ℃

temperature, ℃

0.5

128

307

330

399

5

159

328

364

408

10

179

331

369

417

30

247

339

379

427

50

284

345

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com