Load bearing jumping device of motorized gear shifting gear five-rod mechanism

A five-bar mechanism and gear technology, applied in the field of load-bearing jumping devices, can solve problems such as insufficient load-carrying equipment, and achieve the effect of strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] This embodiment is a load jumping device of a five-bar mechanism of a motorized shift gear.

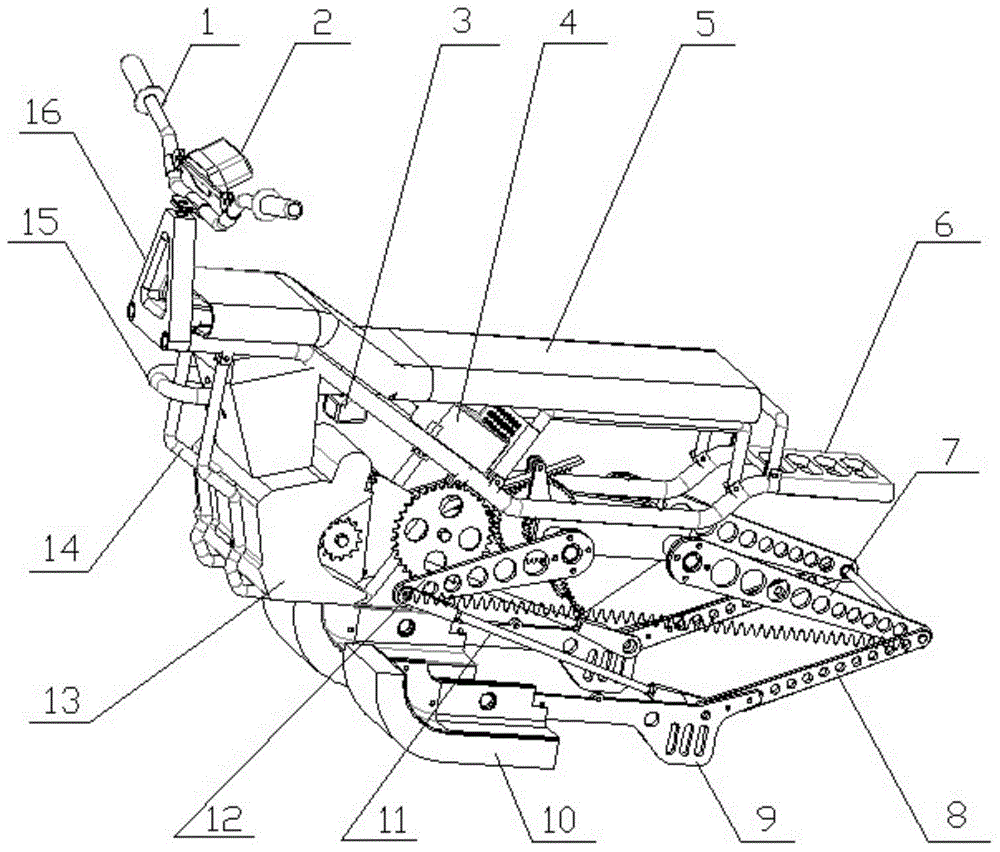

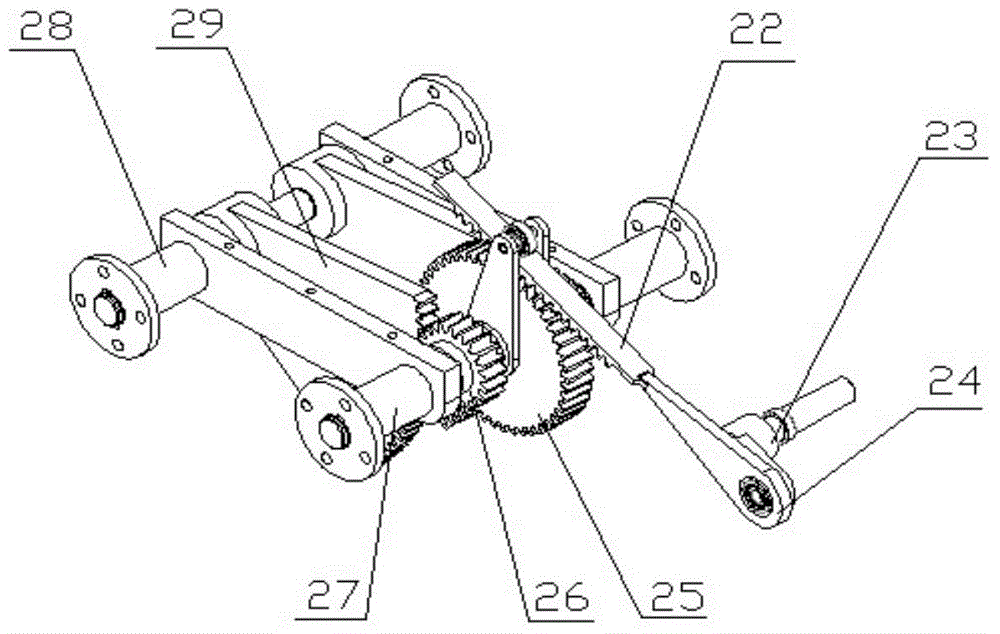

[0029] refer to Figure 1 to Figure 4 , the present embodiment load jumping device is made up of control mechanism, driving mechanism, transmission mechanism, jumping mechanism, and control mechanism is made up of handlebar 1, instrument panel 2, vehicle seat 5, rear seat 6, exhaust pipe 15, faucet frame 16, vehicle Frame 14 is formed, and handlebar and instrument panel are installed on the leading frame and are positioned at vehicle seat front, and handlebar 1 is installed on the leading frame 16 by bolt, and instrument panel 2 is installed between handlebar 1. Faucet frame, vehicle seat and back seat are supported by vehicle frame 14 and exhaust pipe 15.

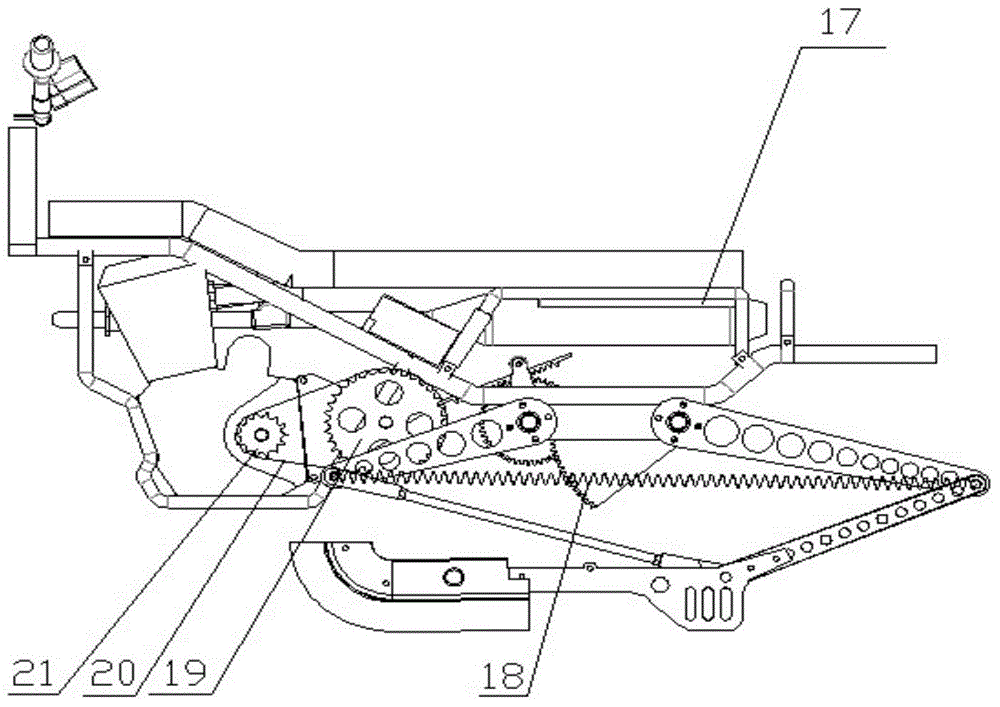

[0030] Driving mechanism is made up of fuel tank 17, carburetor 3, storage battery 4, engine 13, and engine 13 provides power, and engine 13 is fixed on the front portion of car body and is installed with vehicle frame 14 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com