A kind of fatliquoring agent and preparation method thereof

A fatliquoring and dripping technology, applied in small raw hide/large raw hide/leather/fur treatment, leather impregnation, small raw hide/large raw hide/leather hide/fur chemical treatment, etc., can solve the phenomenon of unstable emulsion delamination , can not be stored for a long time, the fatliquor is unstable, etc., to achieve the effect of excellent oily surface, no deepening of the whiteness of the leather surface, and high cleaning rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

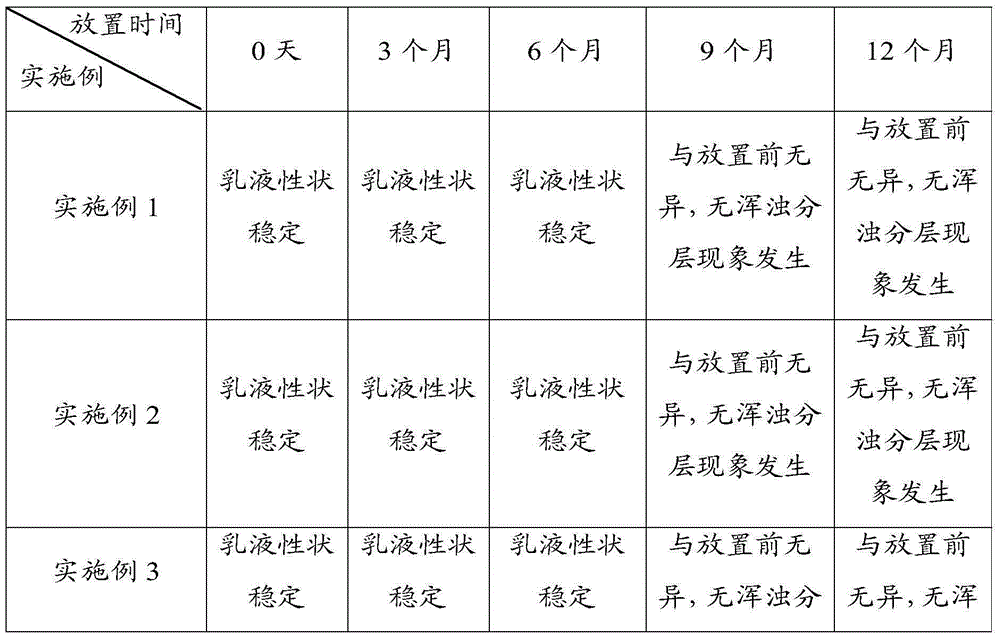

Embodiment 1

[0023] The preparation method of fatliquor is as follows:

[0024] (A) 100kg of ox hoof oil and 40kg of castor oil were mixed and stirred at 40°C for 20min to obtain the first mixture;

[0025] (B) Add 25kg of phosphorus pentoxide into the first mixture, mix and stir at 65°C for 120min, then raise the temperature to 75°C and stir for 120min to obtain the second mixture;

[0026] (C) Under the condition of cooling the second mixture to 50°C, add 4kg of sodium hydroxide solution with a mass concentration of 20% and 15kg of ethanolamine dropwise in turn, then raise the temperature to 65°C and add 50kg of water at a temperature of 60°C, and stir for 60 minutes Fatliquor is obtained.

Embodiment 2

[0028] The preparation method of fatliquor is as follows:

[0029] (A) 200 kg of natural beef hoof oil with a saponification value of 195 and 200 kg of refined castor oil were mixed and stirred at 45° C. for 30 minutes to obtain the first mixture;

[0030] (B) Add 150 kg of phosphorus pentoxide into the first mixture, mix and stir at 75°C for 140 minutes, then raise the temperature to 90°C and stir for 140 minutes to obtain the second mixture;

[0031] (C) Under the condition that the second mixture is cooled to 65° C., 38 kg of sodium hydroxide solution with a mass concentration of 30% is first added dropwise, and the dropwise addition time is 10 min while stirring while adding, then 100 kg of diethanolamine is added dropwise, and then the temperature is raised to Add 200kg of water at 65°C at 70°C and stir for 80 minutes to obtain the fatliquoring agent.

Embodiment 3

[0033] The preparation method of fatliquor is as follows:

[0034] (A) 150 kg of natural beef hoof oil with a saponification value of 200 and 150 kg of refined castor oil were mixed and stirred at 40° C. for 25 to obtain the first mixture;

[0035] (B) Add 100 kg of phosphorus pentoxide into the first mixture, mix and stir at 65°C for 120 minutes, then raise the temperature to 75°C and stir for 140 minutes to obtain the second mixture;

[0036] (C) Under the condition that the second mixture is cooled to 60° C., first dropwise add 30 kg of a mixed solution of potassium hydroxide and sodium hydroxide with a mass concentration of 25%, and the dropping time is 10 min while stirring while adding, and then dropwise adding three Add 80kg of ethanolamine, add dropwise for 60min while stirring, then raise the temperature to 70°C, add 100kg of water with a temperature of 65°C, and stir for 60min to obtain the fatliquoring agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com