Wastewater treatment device in semiconductor production

A wastewater treatment and semiconductor technology, which is applied in the fields of neutralization water/sewage treatment, natural water body treatment, water/sewage treatment, etc. The effect of the blend neutralization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

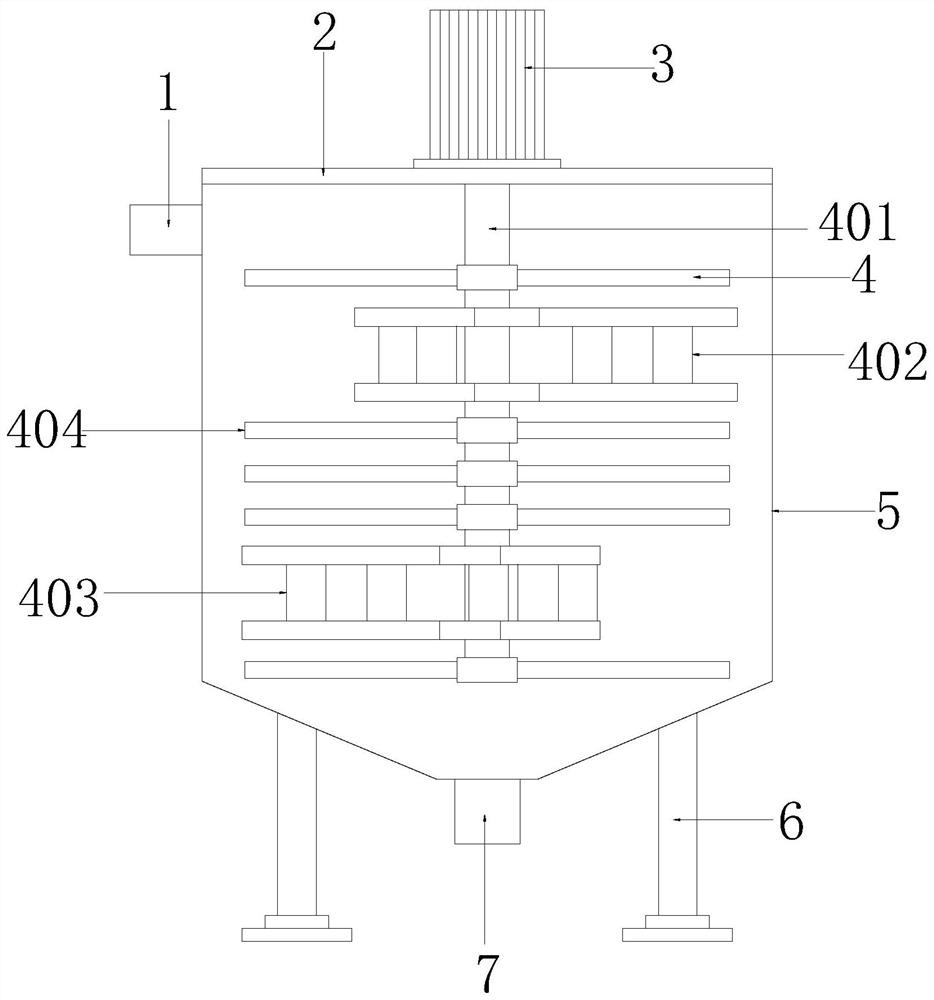

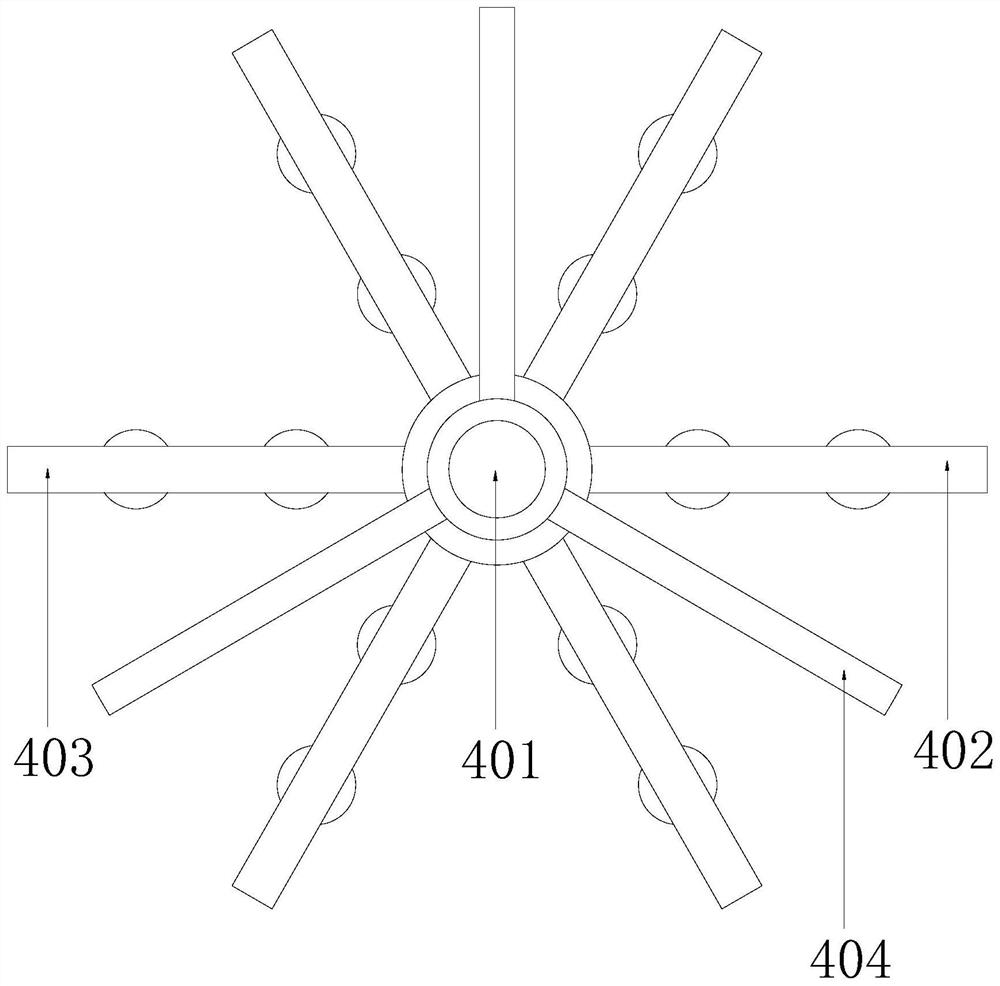

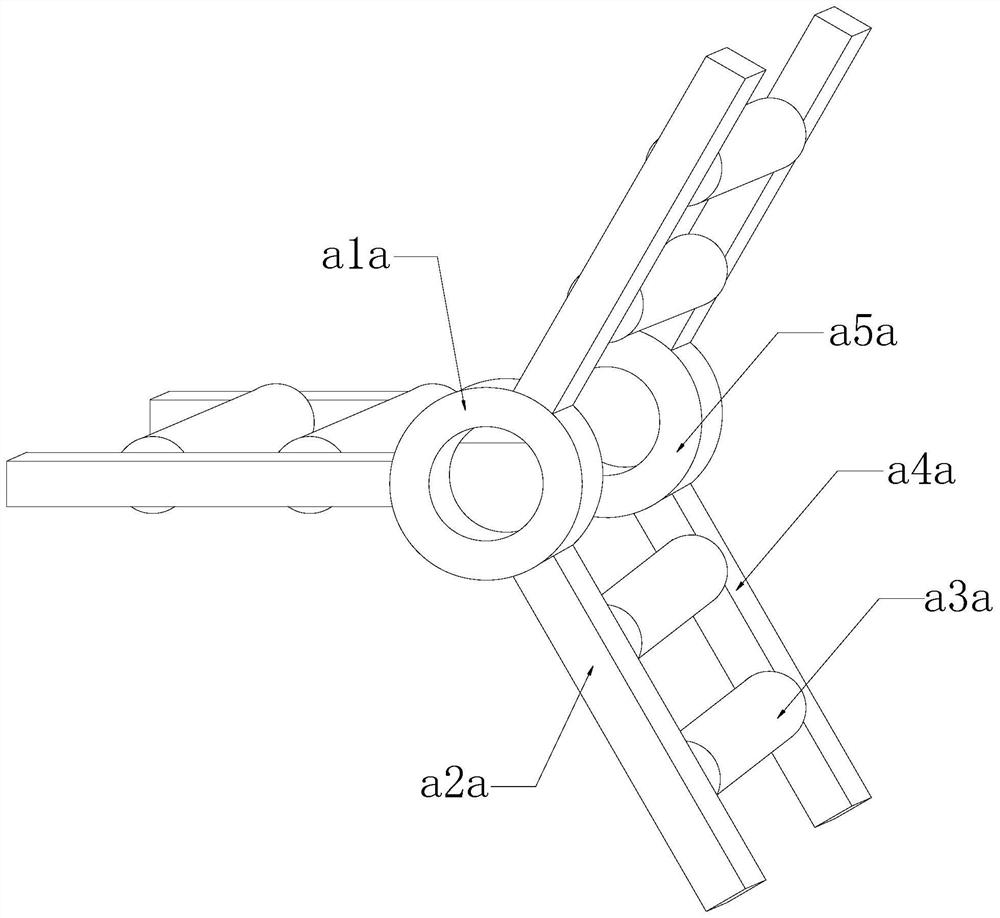

[0029]SeeFigure 1-7 , The present invention provides a technical solution for a wastewater treatment device in semiconductor production: its structure includes a water inlet pipe 1, a top cover 2, an energy-saving motor 3, a mixing and stirring device 4, an acid-base neutralizer body 5, and a supporting leg 6 A water outlet pipe 7, a water outlet pipe 7 is installed at the center of the bottom of the acid-base neutralizer body 5, and the bottom of the acid-base neutralizer body 5 is also vertically connected with a supporting foot 6; The top cover 2 is connected to the top of the receptacle body 5, the top center of the top cover 2 is provided with an energy-saving motor 3, the output shaft of the energy-saving motor 3 is connected with a mixing and stirring device 4, the mixing and stirring device 4 is arranged in the acid Alkali neutralizer body 5, the top of one side of the acid-base neutralizer body 5 is also connected with a water inlet pipe 1, and the mixing and stirring devic...

Embodiment 2

[0036]SeeFigure 1-8, The present invention provides a technical solution for a wastewater treatment device in semiconductor production: its structure includes a water inlet pipe 1, a top cover 2, an energy-saving motor 3, a mixing and stirring device 4, an acid-base neutralizer body 5, and a supporting foot column 6 A water outlet pipe 7, a water outlet pipe 7 is installed at the center of the bottom of the acid-base neutralizer body 5, and the bottom of the acid-base neutralizer body 5 is also vertically connected with a supporting foot 6; The top cover 2 is connected to the top of the receptacle body 5, the top center of the top cover 2 is provided with an energy-saving motor 3, the output shaft of the energy-saving motor 3 is connected with a mixing and stirring device 4, the mixing and stirring device 4 is arranged in the acid An alkali neutralizer body 5, the top of one side of the acid-base neutralizer body 5 is also connected with a water inlet pipe 1.

[0037]The mixing and sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com